In the “BI-FIT”project (Break-In for Fuel Cells Initializing and Testing), Fraunhofer ISE is investigating and optimizing the break-in process, i.e. the initial operation of the fuel cell. To this end, a fundamental understanding of the mechanisms involved is being obtained through scientific, robust analyses and research, and new break-in concepts are being developed so that the duration of the break-in can be reduced to a maximum of 60 minutes. The project is integrated into the “HyFab” project network, which is intended to create a knowledge base for the automotive and supplier industry in order to facilitate research into fuel cell production technologies. | Duration: 08/2022 - 07/2025

more infoResearch Projects

-

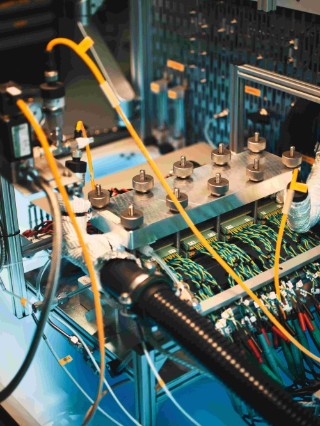

Testing laboratory for in-situ characterization of membrane electrode units for the PEM fuel cell.

-

Segmented along-the-channel (ATC) cell for characterization of local degradation.

An important form of propulsion in the future will be powered by fuel cells. However, the development focus has shifted significantly from passenger cars to freight and heavy duty traffic. At the same time, this increases the expectation of the service life of fuel cells by a factor of five to ten. This aspect is being investigated by the FC-RAT research project coordinated by Fraunhofer ISE. The understanding of the aging processes is to be significantly expanded and deepened. | Duration: 01/2021 - 06/2024

more info -

Multipotentiostaten-System mit segmentierter ATC (Along-the-channel) Zelle zur ortsaufgelösten Charakterisierung.

The development of new fuel cell materials and fabrication processes requires a deep understanding of the complex interaction between the transport processes of the reactants/products, the electrochemical reaction and the microstructure of the active layers. The development of improved fuel cell models in different dimensions and their validation based on experimental data is the goal of the project. | Duration: 06/2019 - 06/2024

more info -

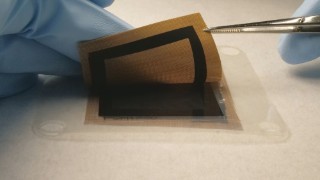

The project is investigating the production of catalyst coated membranes (CCM) with hydrocarbon-based materials as a PFAS-free alternative.

Currently, low-temperature PEM fuel cells, such as those used in mobility, require membranes that typically contain PFSA, a type of PFAS. The project “GIRAFFE” (Generic Investigation Regarding Alternative Fluorine-Free Electrolytes for Fuel Cells) will examine commercially available PFAS-free and low-PFAS materials, with a focus on hydrocarbon polymers. These materials are environmentally benign and could offer advantages in cost and functional merits. The aim is to evaluate the technology readiness level of these materials. | Duration: 01/2024 - 12/2027

more info -

Fuel cell vehicle of the Abfallwirtschaft und Stadtreinigung Freiburg GmbH (ASF) at Fraunhofer ISE’s hydrogen fueling station.

Project in the Business Area: Hydrogen Technologies; Topic: Fuel Cell; Characterization of Fuel Cells Duration: 11/2019 - 06/2024

more info -

HyFaB-BW - HyFab-Baden-Württemberg

Research Factory for Hydrogen and Fuel Cell Technology

Screen printing of a fuel cell catalyst layer.

The »HyFaB-BW« project creates an open, flexible platform for companies in the plant engineering, automotive and supplier industries in which technologies for component production and component qualification can be researched and tested with regard to the fuel cell membrane electrode assembly. This includes further topics such as the investigation of the interrelationship between the material composition of a component or its material structure and its operating behavior. In concrete terms, the project will generate findings that will enable companies to transfer their product developments to series-ready production, depending on the application and fuel cell type. HyFaB is carried out by the Center for Solar Energy and Hydrogen Research Baden-Württemberg (ZSW) (focusing on the cell stack) and the Fraunhofer Institute for Solar Energy Systems ISE (focusing on the membrane electrode unit). | Duration: 11/2019 - 06/2023

more info -

Herstellungsprozess von katalysatorbeschichteten Membranen (Catalyst Coated Membrane, CCM) mit skalierter Fläche (600 cm2) mittels Siebdruckverfahren.

The “HyFaB3” project is developing reference processes for the production of catalyst-coated membranes (CCM) to optimize electrolysis and fuel cell technologies. The aim is to scale the cell area, reduce the precious metal content and increase throughput rates to support the market ramp-up of CCMs.. | Duration: 01/2024 - 07/2026

more info -

OREO

Electrolysis and Fuel Cells: Overall Research on Electrode Coating Processes

The catalyst layer is produced by slot die coating onto a decal transfer foil. For control of the platinum-loading, volume flow, coating velocity and solid content can be adjusted.

The “OREO” project has established robust and reproducible processes for the production of catalyst layers for both fuel cells and electrolyzers. Fraunhofer ISE developed dispersion processes to produce catalyst inks and coating processes such as slot die, screen printing and rotary screen printing to apply the ink. Ex- and in-situ analyses were utilized to understand all the processes involved in the production of the catalyst layers. In addition, a new break-in protocol for the electrolyzer cells was developed. | Duration: 01/2021 - 12/2024

more info -

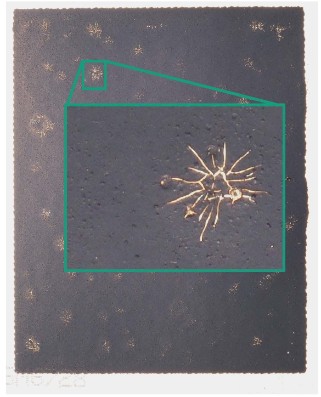

Optische Visualisierung von Rissen in einer Katalysatorschicht, aufgebracht mittels Siebdruck auf einer Decalfolie

The QUALLE project brings together partners from industry and research with diverse expertise in quality assurance (QA) for PEM fuel cells. This HyFab project supports the further development of the industrial-scale production of catalyst-coated membranes (CCM), the heart of the PEM fuel cell, by enabling systematic testing with special analytical methods. Offline quality assurance takes place after production, inline QA occurs on the assembly line and at-line QA uses production-compatible measuring times and conditions. The project develops and validates methods for each of the quality assurance measures. Extensive series of tests of different defects in different manifestations provide a valid assessment of the problem areas and thus significantly reduce rejects. | Duration: 01/2024 - 12/2026

more info -

Full-format catalyst layer on decal transfer foil after the drying process in a continuous convection dryer.

Project in the Business Area: Hydrogen Technologies; Topic: Fuel cell; Duration: 05/2022 - 11/2025

more info