Hydrogen-based, sustainable synthesis products from power-to-X processes – such as ammonia, methanol, and dimethyl ether – will be key energy carriers in the energy system of the future. These hydrogen carriers enable the storage and transportation of renewable electricity, which is subject to local and seasonal fluctuations. Their conversion back into hydrogen closes the hydrogen value chain.

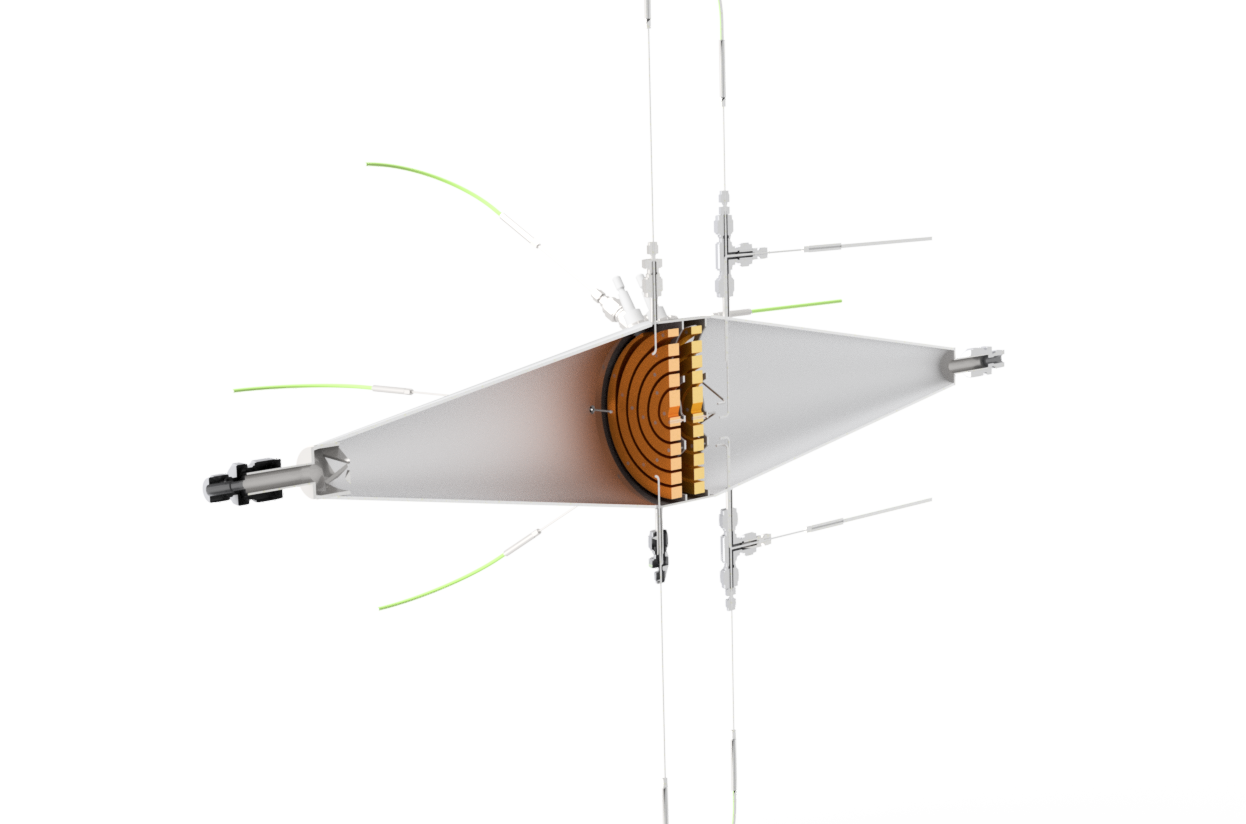

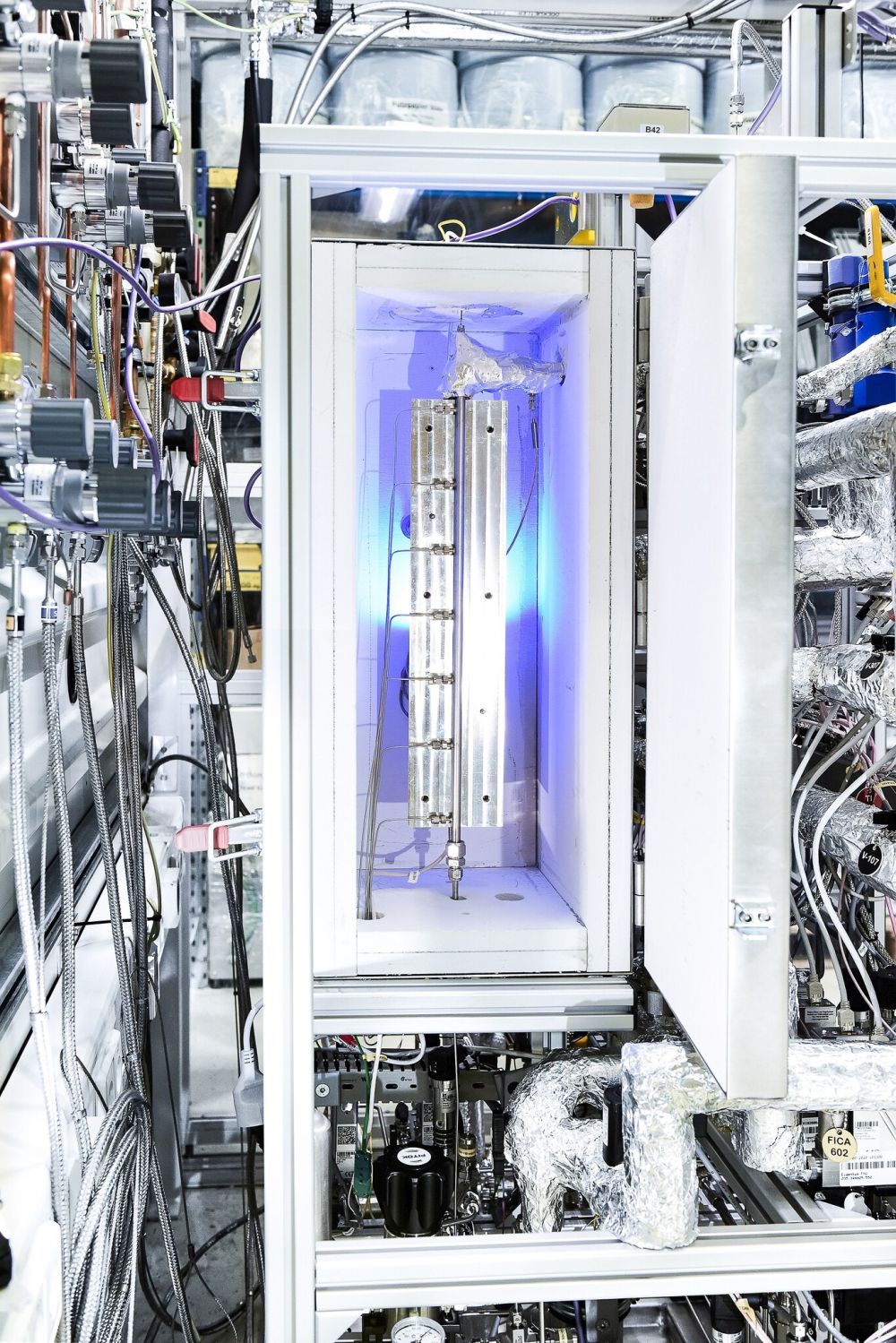

New and efficient conversion processes through catalytic reforming will be crucial for the use of synthesis products in all sectors. Large-scale catalytic reforming processes installed in harbors or industrial areas or smaller-scale catalytic reforming processes at the end user’s site or vehicles will enable the conversion of sustainable synthesis products into hydrogen. The department of Sustainable Synthesis Products focuses on thermochemical processes for hydrogen production.