In the field of “Supercapacitors”, we are researching the characterization of battery materials and optimization methods with regard to electrode and battery cell production.

Electric double-layer capacitors (EDLCs) are devices based on Carbon/Carbon-based electrodes and have the characteristics of being charged and discharged very fast (within seconds) and can therefore be used where high power is required. Despite the high-power capability, these devices have limitations in energy density.

One of the strategies to enhance the energy density is to design a hybrid system where one of the electrodes is a capacitive one (e.g. activated carbon) and the other electrode is a faradaic one (e.g. a battery material).

This includes:

- Lithium-ion capacitors – also called asymmetric capacitors or superbatteries – are typically based on a graphite or Li2Ti5O4 negative electrode (the faradaic electrode) and an activated carbon positive electrode (the double layer-type electrode) and already found a niche in the market.

- Sodium-ion capacitors where the faradaic electrode is typically represented by hard carbon can represent the next generation of more sustainable high-power energy storage devices.

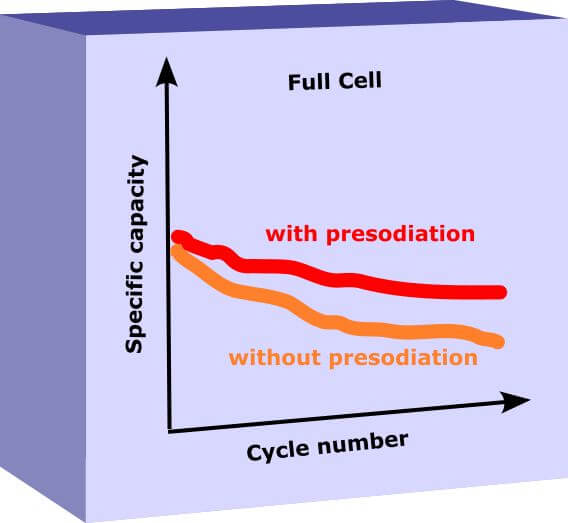

Differently than lithium- or sodium-ion batteries, these types of devices don't contain a lithium or sodium source at the positive electrode and therefore strategies of pre-metallation need to be considered.