Energy Provision

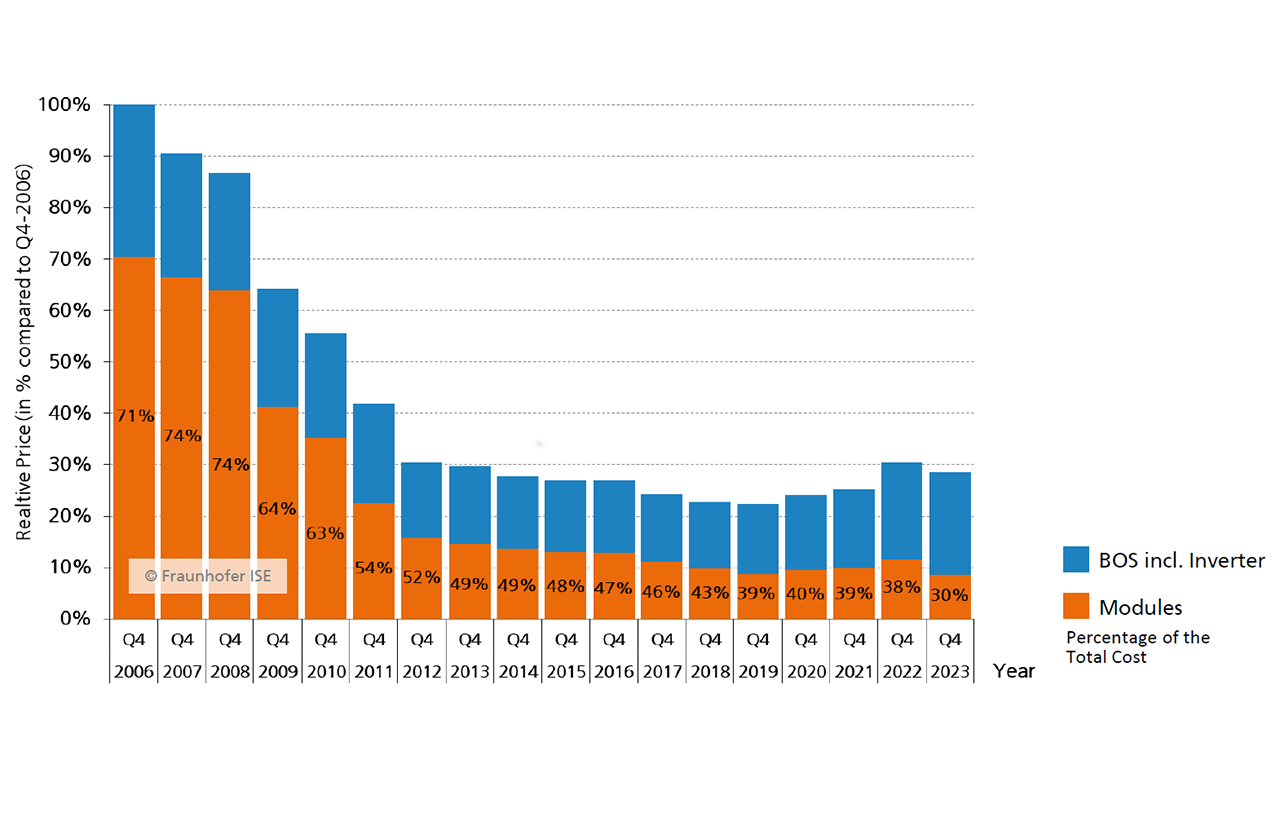

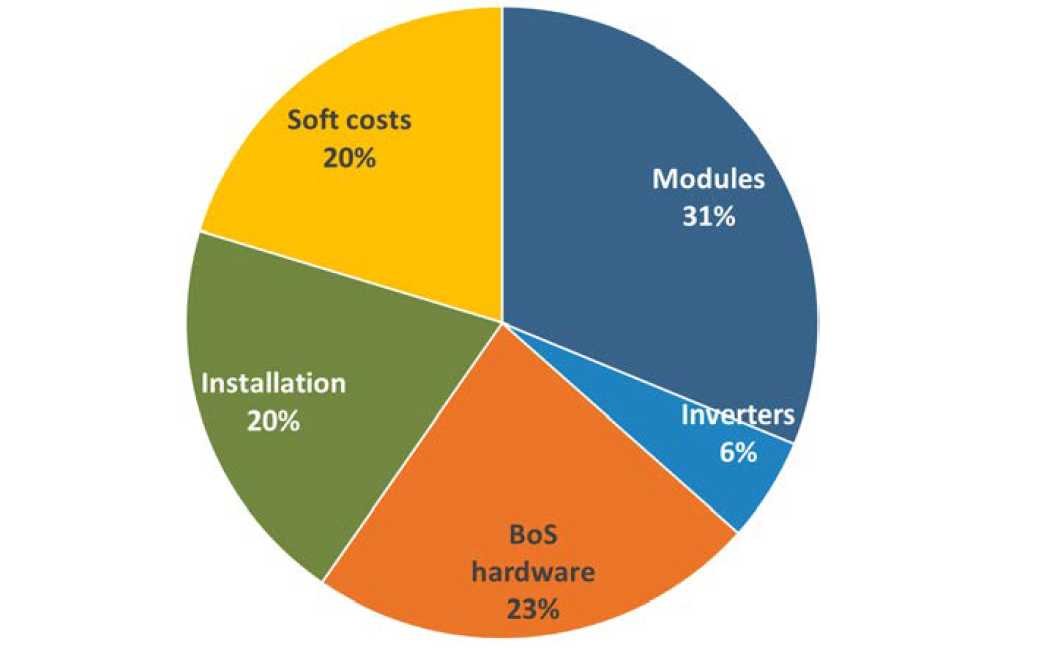

Around 73 terawatts of photovoltaic capacity alone must be additionally installed worldwide by 2050. At the same time, the PV industry is subject to enormous cost pressure. The price per installed kWp has dropped by about 14 percent per year over time, due to advances in technology and economies of scale in production. Today the costs for the installation and BoS hardware account for over 40 percent of the total costs. In future, savings in these areas will have a greater impact on the overall price. Medium voltage is a key lever in reducing energy generation costs.

Higher system voltages result in reduced cable currents, leading to savings in many areas. For example, the cable diameters, or cross-sections, can be greatly reduced, thus saving raw materials like copper and aluminum. Doubling the output voltage, that is, halving the output current, leads to a 75 percent reduction in the cable cross-section. According to the International Energy Agency’s (IEA) report "Global Critical Minerals Outlook 2024", copper demand will exceed the available supply from 2025 on, and thus raw material prices are expected to rise in the future. The European Union also identified in the “Study on critical raw materials for the EU 2023” aluminum as further critical raw material with a high economic importance and a high supply risk. However, the material costs are not the only savings potential for cables. Installation costs can be saved by smaller cables as well, since they are generally easier to lay and connect than large cable cross-sections.

Another advantage of medium voltage is that the higher voltage allows to increase the power of the individual subsystems. Today's PV power plants mostly use subsystems between 3 and 5 MVA in size, whose output cannot be significantly increased due to the large copper cross-sections necessary for the current in the low voltage range. By switching to medium voltage, a transformer with the same cross-section can transmit a higher power (10-12 MVA at 1,500 V). For PV power plants of the same size, the plant with medium voltage technology requires a smaller number of transformers and switchgear and therefore needs fewer construction measures and lower installation costs, while freeing up space for additional PV modules at the same time.

The Technological Course has been Set

The move to medium voltage (MV) at system level was made possible by the development of high voltage silicon carbide (SiC) components for power electronic systems, e.g. PV inverters. These are now available on the market with voltage classes of up to 3.3 kV. In the "MS-LeiKra" project, Fraunhofer ISE demonstrated the technical feasibility of the world's first medium-voltage photovoltaic (MS-PV) string inverter with an output voltage 1,500 VAC at a power of 250 kVA. Work is currently underway on the first MS-PV pilot systems.

Overcoming Obstacles Together

Despite the steadily increasing output power of PV inverters, the increase in system voltage has stagnated since 2018. This is due to the definition of low voltage, which ends at 1,500 VDC or 1,000 VAC. All existing PV standards up to now refer to this limiting value. An increase beyond this value is currently hindered by the existing standards, as they must first be adjusted, or rather extended, to meet the basic standards for medium voltage applications. To this end, a European consortium, made up of representatives from all trades involved in large-scale PV power plants, has been formed to jointly address and compile the technological and normative requirements necessary for the leap to medium voltage. Due to the hugely rising demand for raw materials, it is no longer a question whether medium voltage technology will be introduced, but rather who will be the first players in this promising market.

R&D Services

We perform R&D services for PV module manufacturers, solar contractors that perform EPC work, manufacturers of power electronic devices and systems, energy suppliers, transmission system operators, power plant operators as well as project developers, system integrators and system manufacturers. Our range of services include:

- Development of highly efficient PV modules

- Measurements and tests for type suitability and type approval of PV modules

- Module analysis, damage assessment and reliability of PV modules

- Potential analyses, yield assessments and feasibility studies for PV power plants

- Troubleshooting and fault analysis in the laboratory and onsite at PV power plants

- Development of efficient high-performance power converters for low and medium-voltage applications

- Feasibility and concept studies for high-power electronic systems

- Advice and expert opinions on power electronics issues