Fraunhofer ISE develops physics-informed AI models for fast and interpretable analysis of solar cells and power plants. With our novel methods, we aim to characterize solar cells based on measurements that can be collected for each sample during production. The physical information is integrated into the modeling in different ways.

This will be illustrated using two examples:

Physics-Informed AI Models for Interpretable Data Analysis

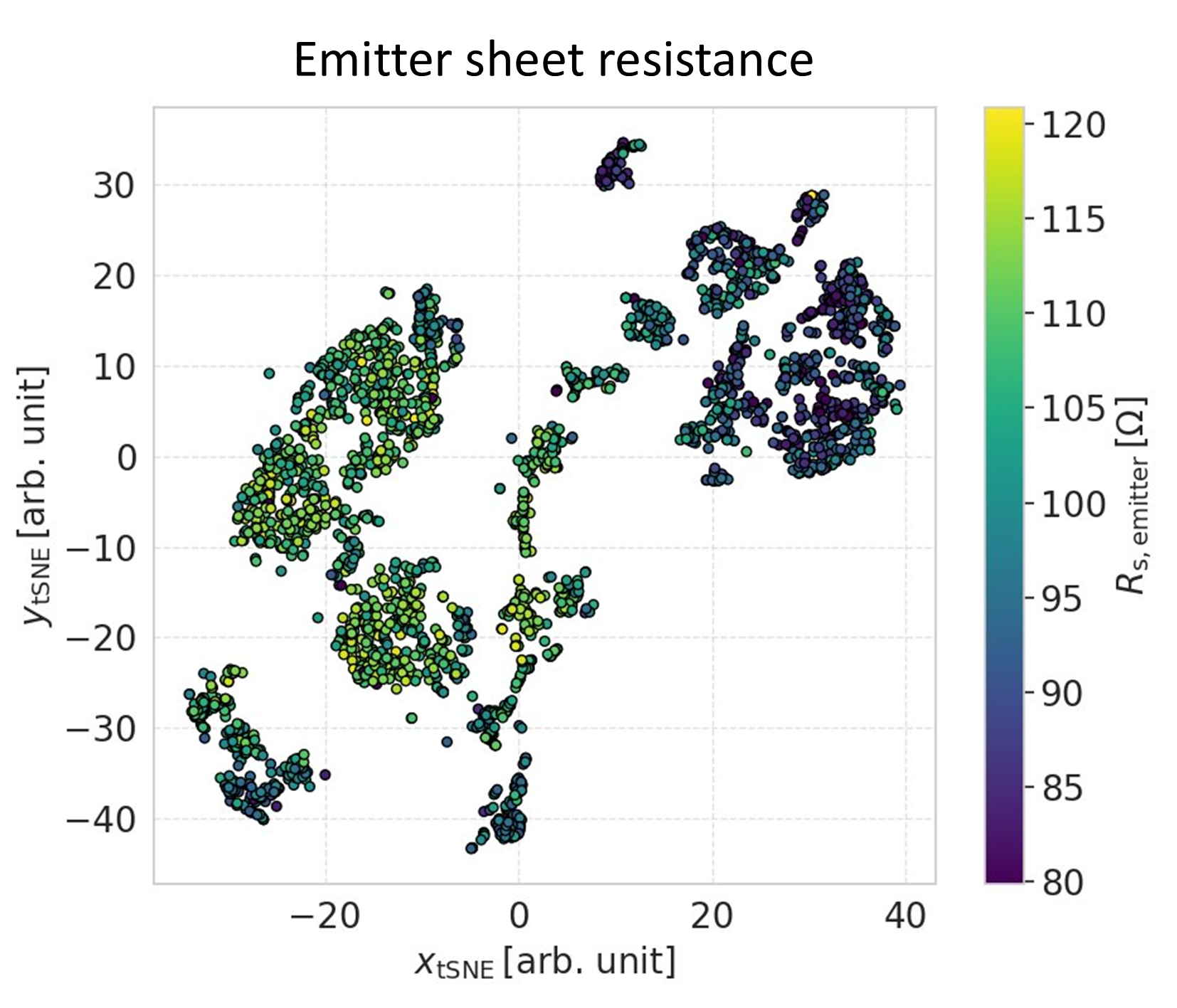

Hybrid Models and the Physical Digital Twin

Fraunhofer ISE has developed a digital twin of the solar cell that combines deep learning models and physics-based simulation methods. This digital twin enables real-time quality control and inline loss analysis of solar cells solely based on inline accessible measurement data and thus creates the basis for targeted and efficient process optimization. By combining simulation-based models and expert knowledge with machine learning, an interpretable and physically accurate representation of each individual solar cell is created. The physics-informed approach enables the fusion and compression of measurement data and thus efficient storage and analysis of the measurement data collected on the workpiece.

Our R&D services for the digital twin include:

- physical digital twin: development of methods for real-time quality control and inline loss analysis for novel solar cell concepts to optimize production

- production evaluation: evaluation of solar cells from your production with data measured at Fraunhofer ISE

- customer transfer: transfer of the algorithms to the customer-specific solar cell production and adaptation to the measurement systems implemented at the customer's site

- concept development: development of concepts for efficient data analysis and data storage in production and for the integration of expert knowledge via suitable operating modules

- design optimization: loss and potential analysis based on hidden physical parameters that can be derived

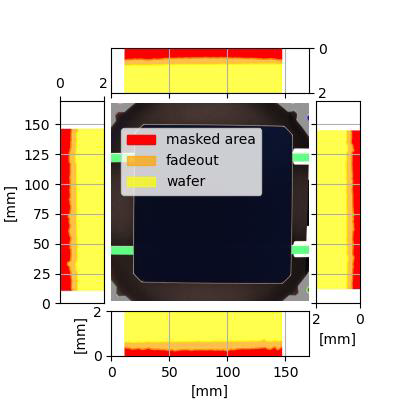

Layer Thickness Measurement

Fraunhofer ISE has developed a novel, physics-informed machine learning model for fast, precise and full-area determination of the layer thickness of transparent conductive oxides (TCO) in solar cells. Using multispectral images and synthetic training data, this model enables comprehensive quality control and process analysis during the production process. The technology enables the creation of complete thickness maps of the TCO layer in just one second and thus improves quality control in the production of heterojunction (HJT) solar cells and thus their efficiency and reliability.

Our R&D services for layer thickness measurement include:

- fast layer thickness measurement: implementation of the machine learning model for fast and quantitative layer thickness determination in the production process; transfer of the models to functional layers of alternative cell structures

- production evaluation: evaluation of solar cells from your production with data measured at Fraunhofer ISE

- quality control: comprehensive inline quality inspection of the TCO layer thickness distribution to optimize cell performance

- process optimization: analysis and adaptation of masking procedures to reduce shunts and increase cell efficiency

- training and implementation: provision of the necessary know-how for the integration and use of machine learning solutions in existing production lines