| Duration: | 01/2021 - 12/2024 |

| Contracting Authority/ Sponsor: |

Federal Ministry of Digital Affairs and Transport (BMDV) |

| Project Partners: |

|

| Project Focus: | |

OREO

Electrolysis and Fuel Cells: Overall Research on Electrode Coating Processes

The catalyst layer is the key element of fuel cells and electrolyzers, where the electrochemical reactions take place. It determines not only the overall cost of the system, but also its lifetime. Understanding the relationship between performance and catalyst layer properties is crucial for market ramp-up. The “OREO” project has established robust and reproducible processes for the production of catalyst layers for both fuel cells and electrolyzers. Fraunhofer ISE developed dispersion processes to produce catalyst inks and coating processes such as slot die, screen printing and rotary screen printing to apply the ink. Ex- and in-situ analyses were utilized to understand all the processes involved in the production of the catalyst layers. In addition, a new break-in protocol for the electrolyzer cells was developed.

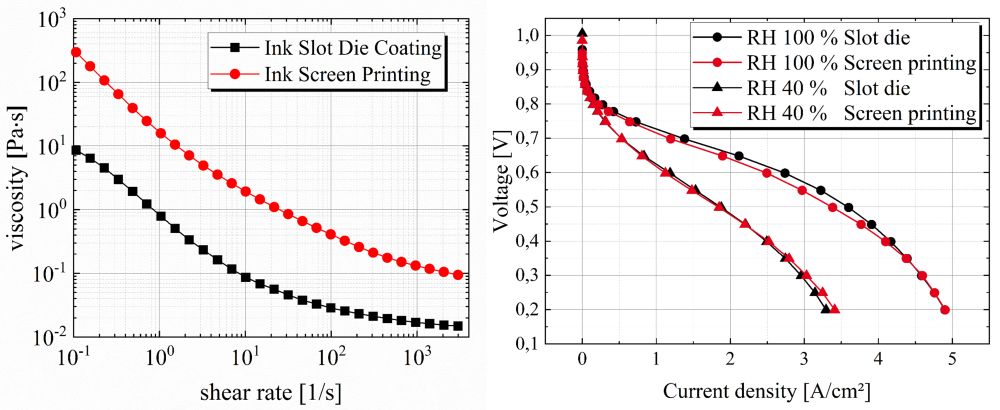

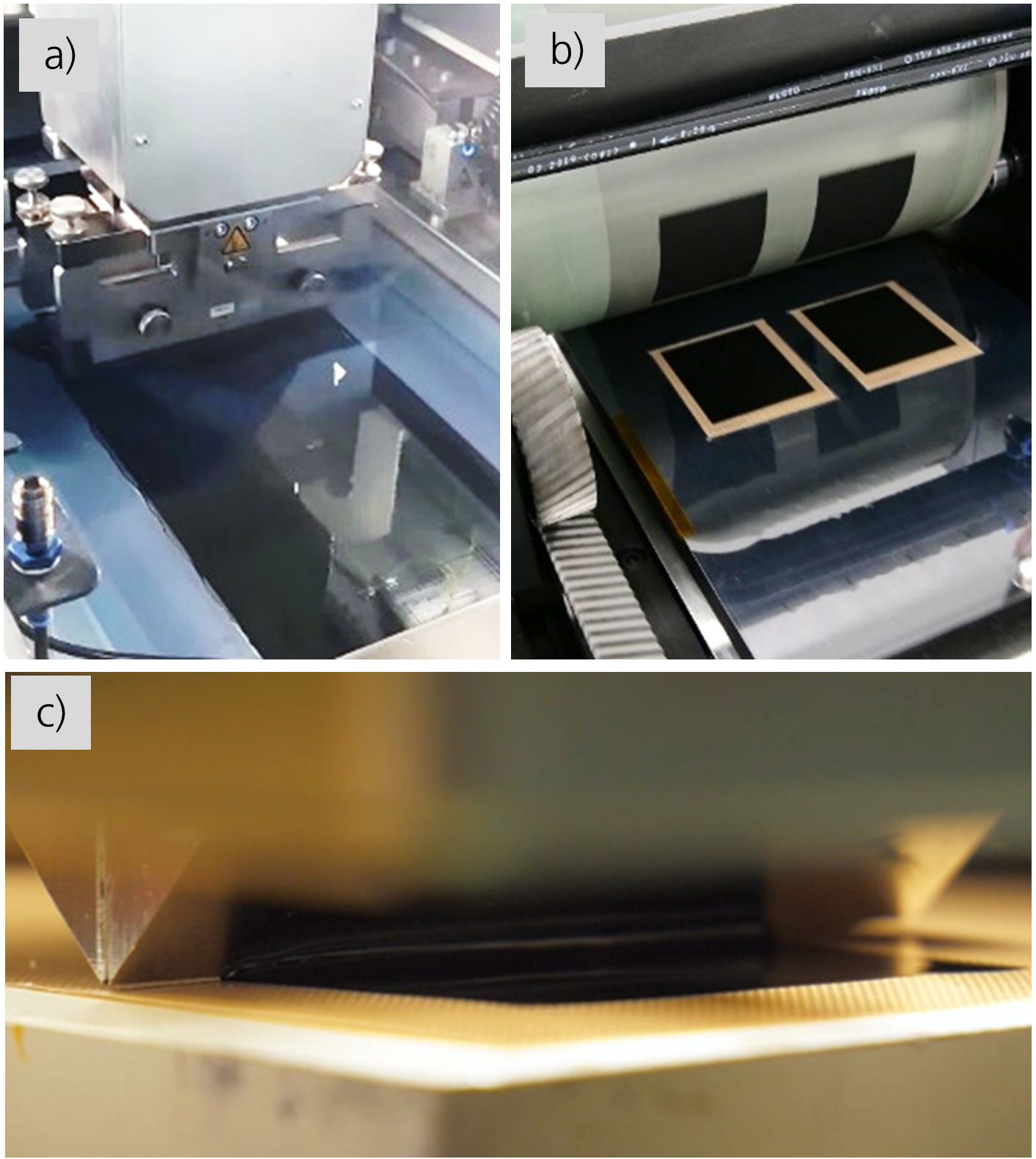

The research focus of the “OREO” project was to understand the production processes of the catalyst layers of PEM fuel cells and electrolyzers. In particular, the effect of material composition and production methods on the performance of these cells has been investigated. The aim was to understand the ink viscosity and coating velocity and to explore further ex-situ measurement methods. Ink rheology is crucial for stable coating processes and is influenced by solvents, solid content, ionomer-to-carbon (I/C) ratio, and platinum-to-carbon (Pt/C) ratio used to make the ink. Coating parameters control the wet layer thickness and determine the homogeneity of the catalyst layers. Together with the drying parameters, they can affect the performance of the cells. In this project, we were interested in further developing screen printing, both flatbed and rotary, and exploring the slot die coating as a coating technique (see Figure 1).

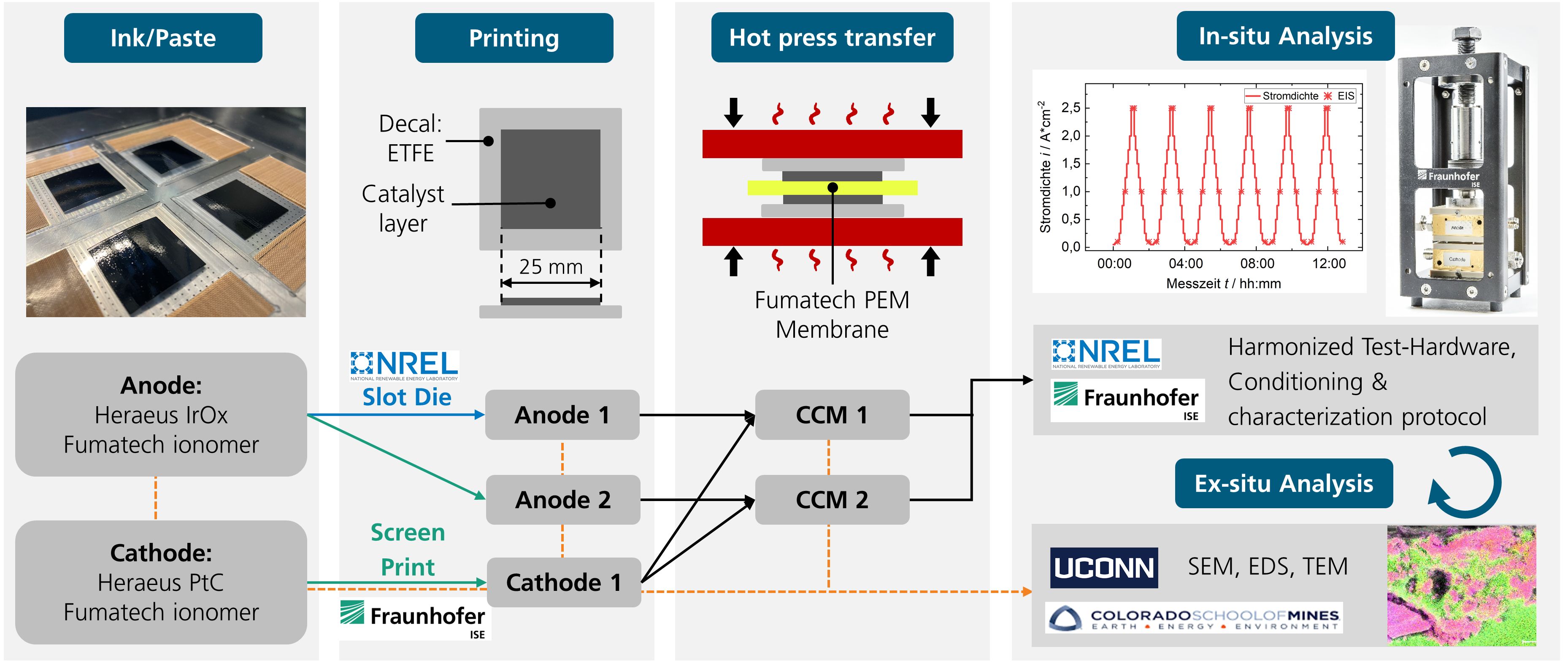

In addition, round robin tests were conducted to understand the interlaboratory variation. Together with our US partner, NREL, we compared screen printing and slot die coating for PEM electrolysis. Catalysts (iridium oxide: anode and platinum on carbon: cathode) from partner Heraeus and ionomer and polymer electrolyte membranes from partner Fumatech were used for the experiment, as shown in Figure 2. The focus of the experiment was to compare the anodes with all cathodes printed at Fraunhofer ISE. The anodes were then printed according to each institute’s process, with anode 1, printed by NREL using slot die and anode 2 printed by Fraunhofer ISE using screen printing.

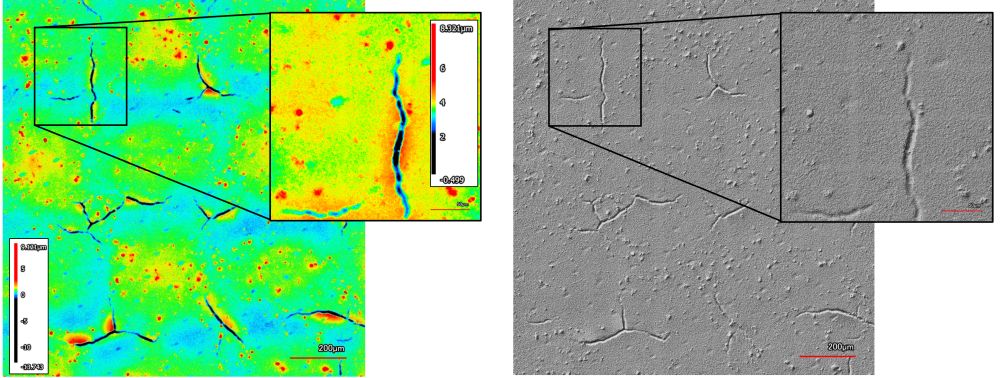

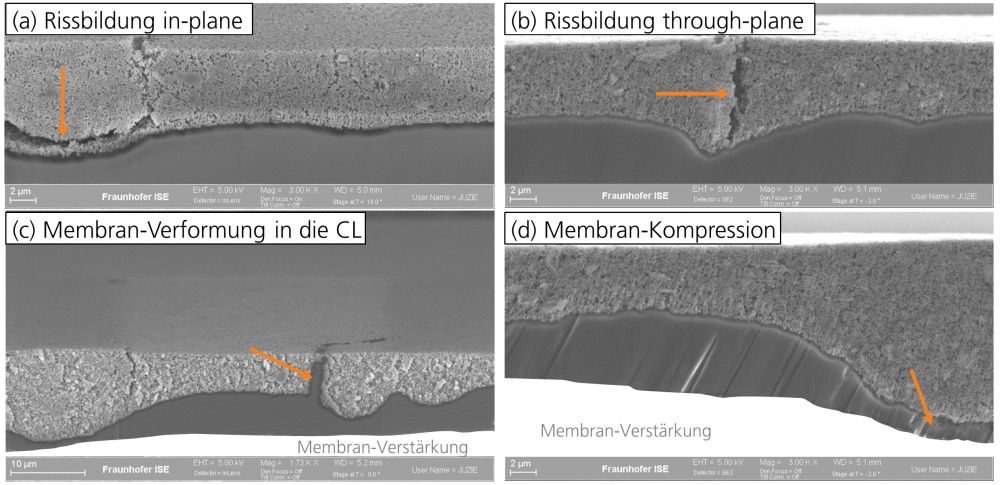

Throughout the project, inhomogeneities in the catalyst layer were detected and analyzed. Unsuitable ink dispersion methods lead to agglomerates in the ink which can cause cracks and local membrane compression after decal transfer (see Figure 3). Further, the quality of the decal foil can play a role in surface inhomogeneities of the printed layer (see Figure 4). In OREO, we identified and classified different types of defects, such as: cracks, scratches, craters, etc. A neural network model was trained with optical images to classify defects on a catalyst layer. This model proved to be very robust and will be used for defect classification at ISE.

In-situ charcterization was used to understand the effect of the different production processes on the overall performance. An example for fuel cells is shown in Figure 5. Here, it can be seen that slot die coating and screen printing exhibit comparable performance, despite differing ink properties.

Finally, a cost analysis model considering the full life cycle of the production of the catalyst layers was developed in this project.

The project "OREO" (Electrolysis & Fuel Cells: Overall Research on Electrode Coating Processes) was funded by the German Federal Ministry of Digital Affairs and Transport (BMDV) within the framework of the National Innovation Program Hydrogen and Fuel Cell Technology with a total of 2.679.978,00 Euro. The funding guideline is coordinated by NOW GmbH and implemented by Project Management Jülich (PtJ).