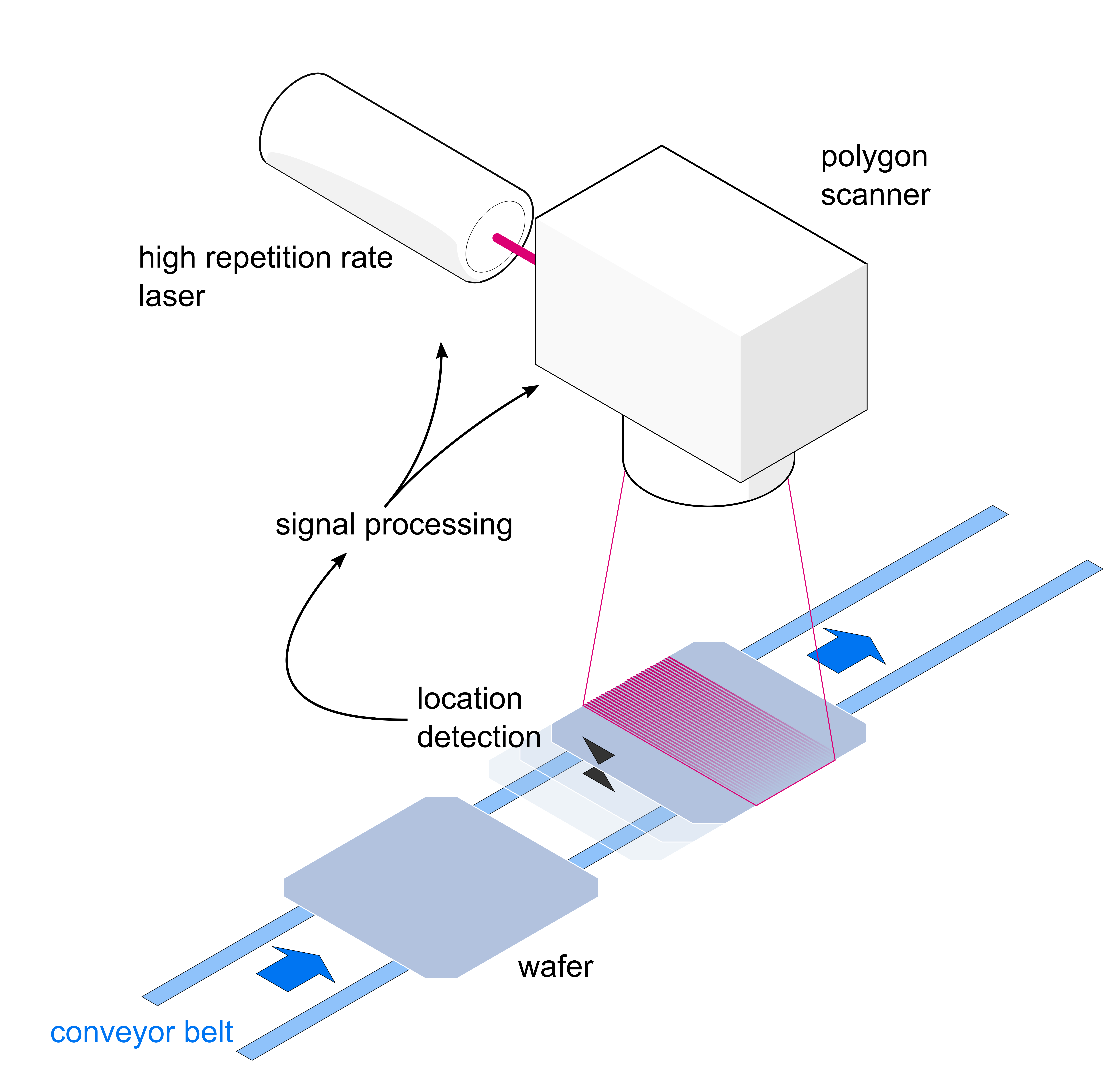

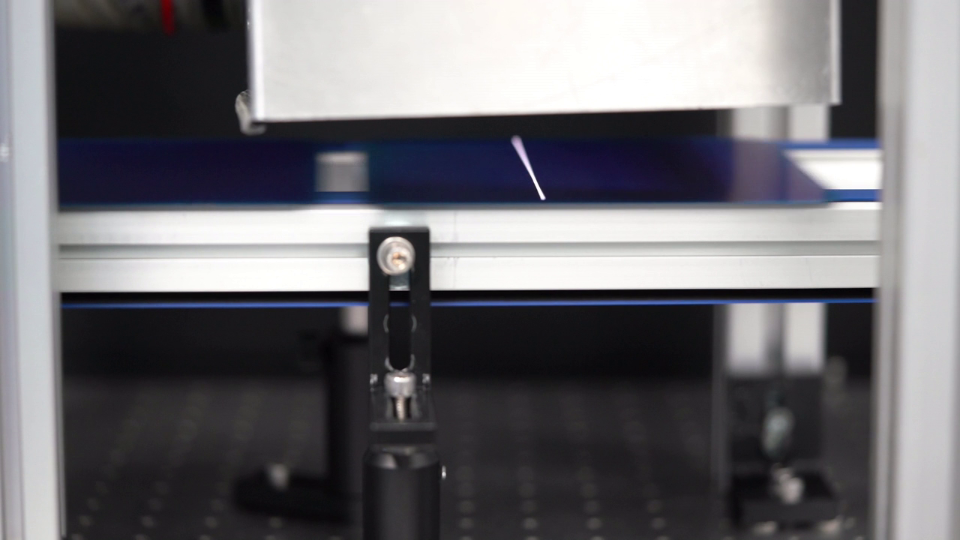

Galvanometer scanners, which can move the beam at up to 50 m/s over the sample by means of two mirrors, are usually used for fast beam alignment in laser material processing of silicon solar cells. Significantly higher processing speeds can be achieved with polygon scanners. Here, the laser beam hits a rotating polygon wheel consisting of several facets. The laser beam is then reflected from the facet onto the sample. Using a galvanometer mirror, the laser beam is also deflected transversely to this fast axis so that two-dimensional structures can be processed. Due to the high rotational speed of the polygon wheel, speeds of more than 1 km/s can be achieved, depending on the imaging optics.

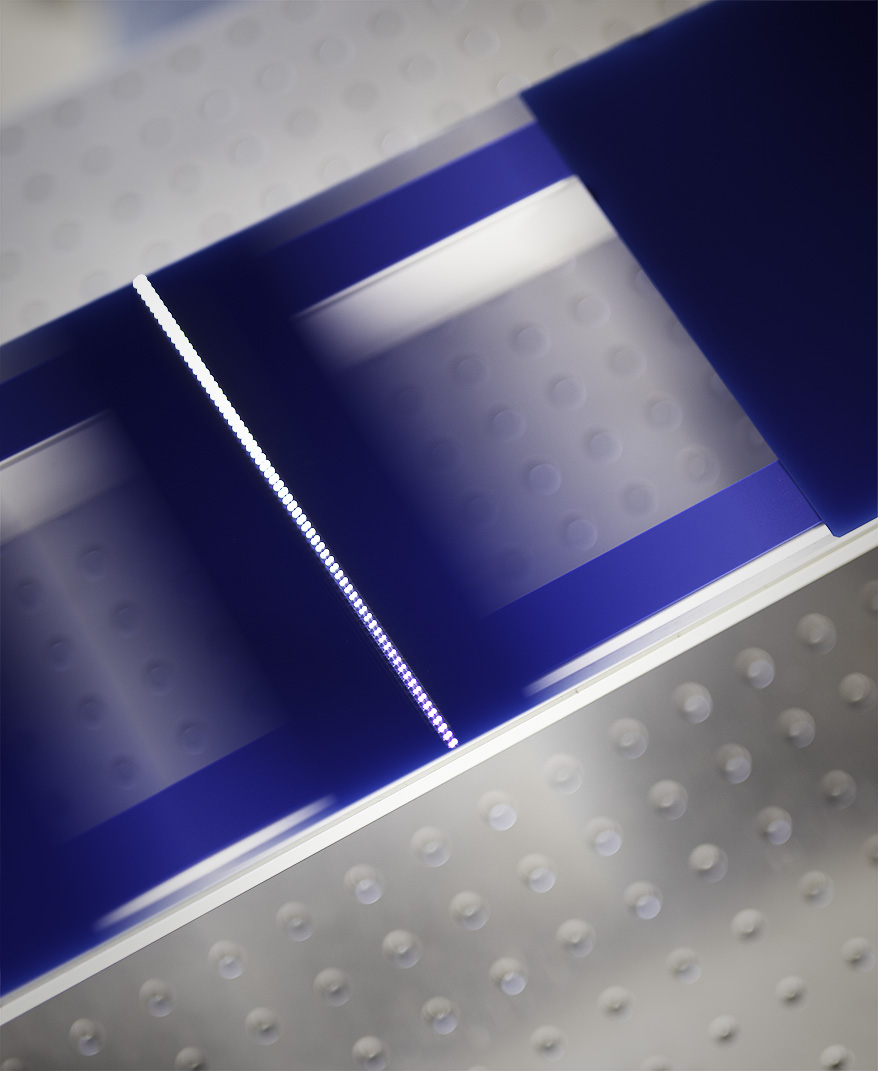

Linear or rotary table systems are often used to transport the silicon wafer to the processing position. With both of these system concepts, the wafer is halted after it has been moved to the processing position and then laser processing is performed. With on-the-fly processing, however, the wafer lies on a conveyor belt and is processed as it passes underneath the laser scanner. This allows for a higher throughput, since there is no need to stop the conveyor belt and the distance between the individual wafers can be minimized.

Special optical sensor technology detects the position of the workpiece, enabling the laser process to be triggered at the right time.