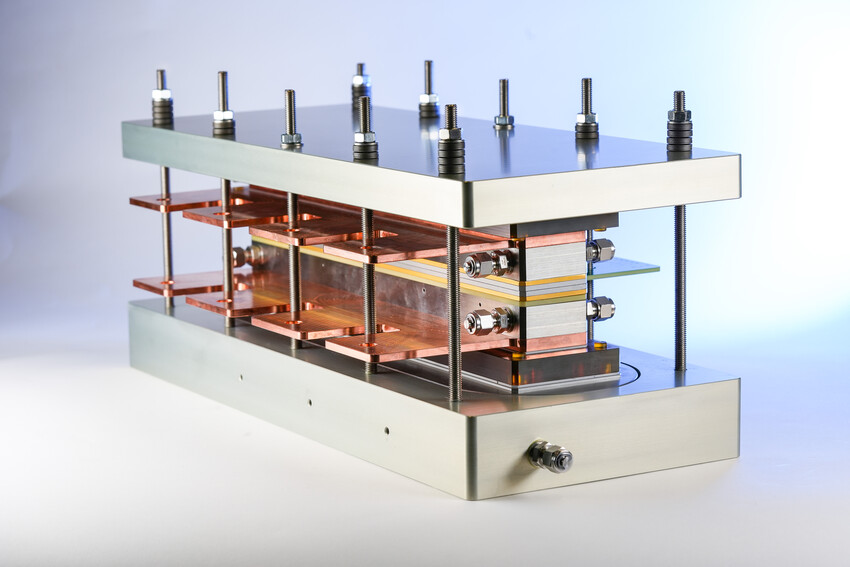

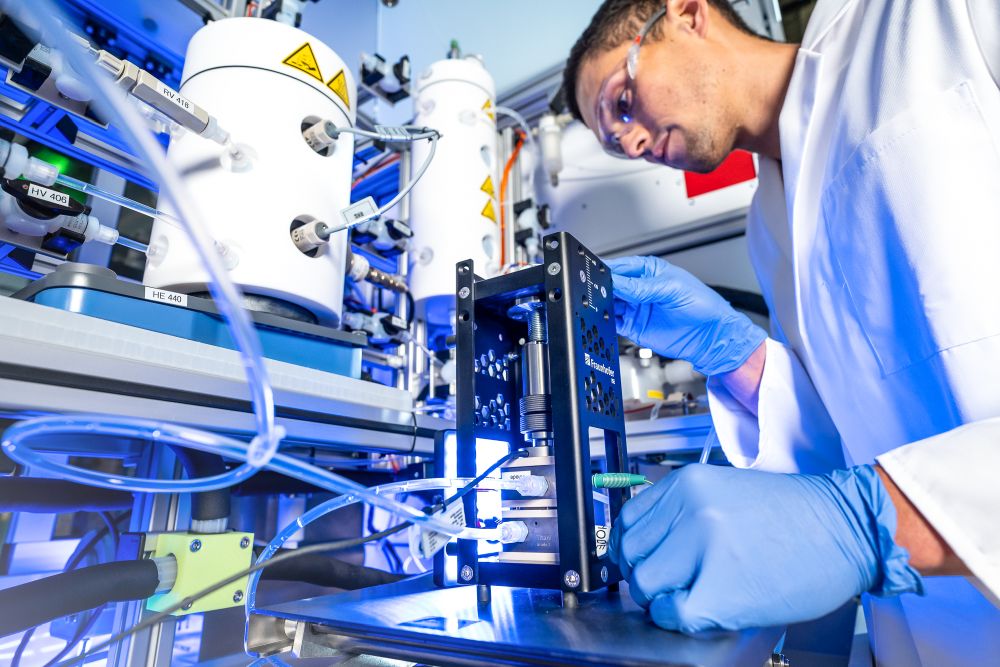

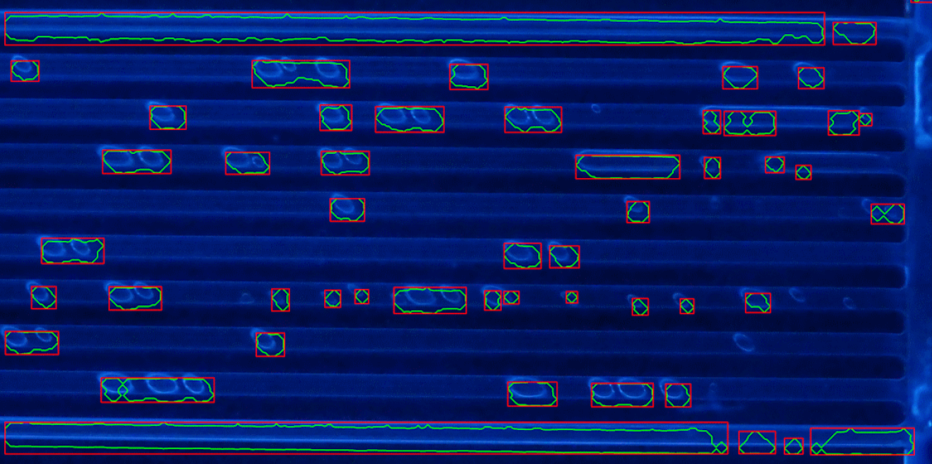

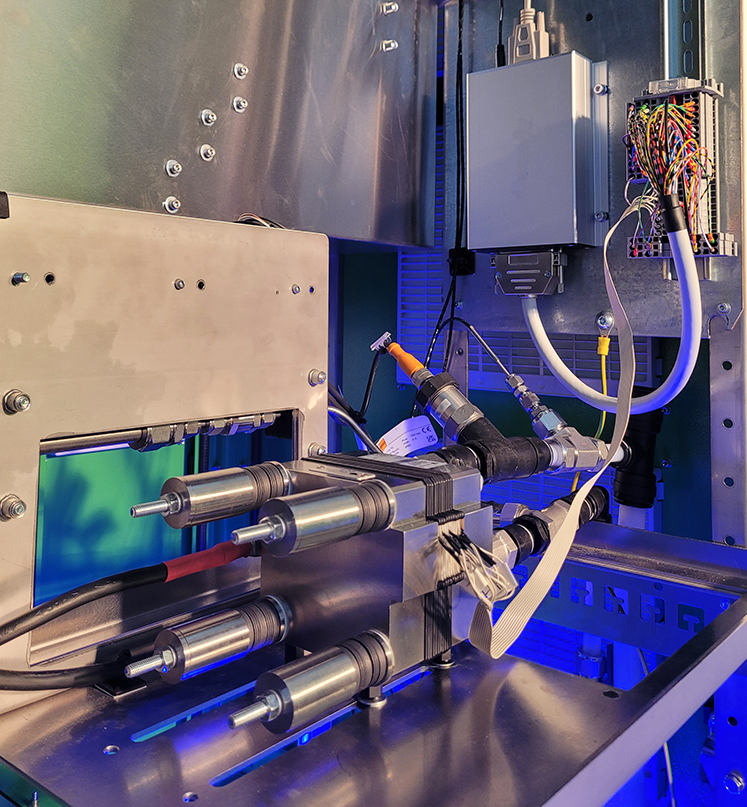

In our 700 m² electrolysis laboratory, we conduct research into innovative technologies for the development and optimization of high-performance materials and components for water electrolysis with proton exchange membranes (PEM) and anion exchange membranes (AEM). We develop novel cell and stack designs, carry out short-term electrochemical measurements with our customized test benches, and analyze the material properties of the components using various ex-situ measurement methods. To understand aging mechanisms and to derive rapid aging tests, we examine the durability of the cell components using automatic long-term measurements.

In production research, we concentrate on manufacturing processes for membrane electrode assemblies (MEA). We optimize manufacturing processes from catalyst powders to MEA and support our customers in implementing industrial solutions for series production.

By monitoring our customers’ electrolyzers, we round off our range of services with the development of operational management concepts, including measurements for condition-based maintenance approaches.

Our services are aimed at companies and research institutions that develop and manufacture components and systems for hydrogen production.

Our interdisciplinary team has many years of experience in the development and characterization of materials and components for electrolysis and in the engineering of electrolysis test benches and systems.