| Duration: | 11/2019 - 06/2024 |

| Contracting Authority/ Sponsors: |

Federal Ministry for Digital and Transport (BMDV) |

| Project Partners: |

|

| Webseite: | Project page of NOW GmbH |

| Project Focus:: |

H2Fuel – Development of Revised Limit Values for Harmful Components in Hydrogen Fuel

Depending on the production and transportation process, hydrogen for fuel cell electric vehicles (FCEVs) contains impurities such as hydrocarbons, which affect the efficiency and service life of fuel cells. The hydrogen fuel quality standard ISO 14687:2019 therefore contains specifications for maximum permissible concentrations of harmful components, which are determined in comprehensive tests. The aim of the “H2Fuel” project is to check these limit values with regard to current fuel cell configurations, application-oriented driving modes and overall system costs.

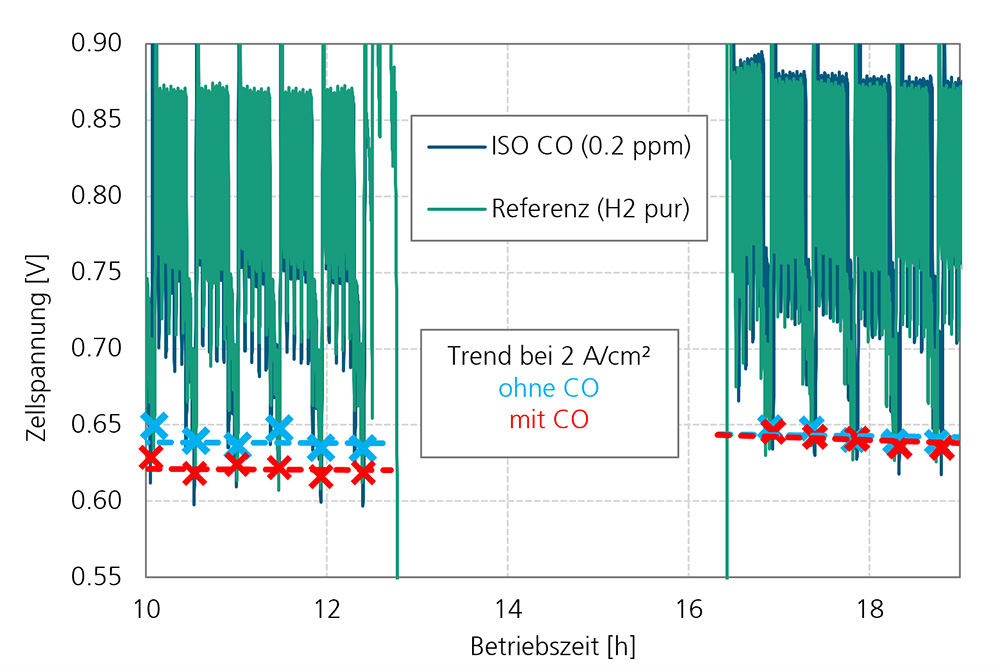

Usage data from FCEVs show that frequent load changes, such as those that can be simulated using the Fuel Cell Dynamic Load Cycle (FC-DLC), as well as starting and stopping the system mitigate undesirable contamination effects. In combination with operating modes adapted to contaminated hydrogen, this could argue for a reduction in certain impurity limits.

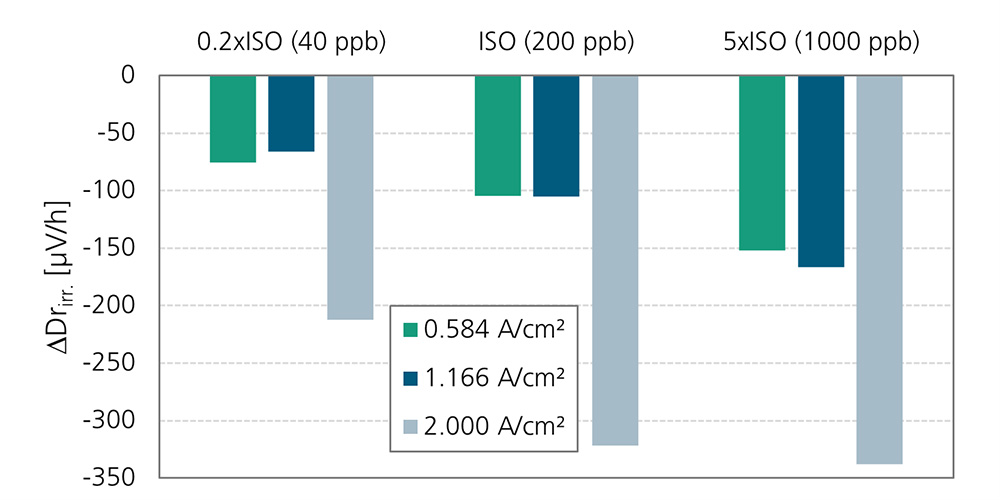

On the other hand, fuel cell manufacturers aim to reduce the amount of platinum per stack in fuel cells for cost reasons, which can have a negative impact on the system’s impurity tolerance. Efficiency losses and irreversible damage to the electrodes are more pronounced if only a small buffer against the loss of active catalyst surfaces is available. The concentrations of the respective hydrogen impurities must therefore be limited to such a low level that no contamination-related, irreversible degradation occurs despite long operating times.

If the requirements for hydrogen purity are high, the production costs of hydrogen and thus the operating costs of FCEVs increase. If the requirements are low and impurity concentrations are high, irreversible damage to the fuel cell can occur in the worst case, which can only be overcome by more robust fuel cell stacks.

Using individual cell measurements and models, H2Fuel compares the costs incurred by increased H2 post-purification and analysis on the one hand, and more robust stacks on the other, in order to ultimately justify adjustments to the ISO standard for hydrogen delivery quality at fueling stations, taking into account current and future fuel cell configurations and the cost-effectiveness of the overall system. Fraunhofer ISE is carrying out individual cell measurements for various impurities such as carbon monoxide, toluene, and formic acid in order to investigate their long-term effects.

The results will be submitted to the standardization groups to help launch the ISO revision process.

The “H2Fuel” project is funded by the German Federal Ministry for Digital and Transport with EUR 1,575,329 as part of the National Innovation Programme for Hydrogen and Fuel Cell Technology. The funding is coordinated by NOW GmbH and implemented by Project Management Jülich (PtJ). Funding reference number: 03B11014