In our “Lab Battery Materials and Cell Production”, we conduct research on ~1,500 m2 of innovative technologies for the development and optimization of high-performance battery materials, efficient manufacturing processes and sustainable solutions for the energy storage of the future. In our laboratories, we can develop processes on a laboratory scale and scale them up to a pilot scale in order to optimize them for industrial application.

Lab Battery Materials and Cell Production

Our Services in the "Lab Battery Materials and Cell Production" Include:

Synthesis for Cathode and Anode Active Materials

For the production of cathode and anode active materials, different options and scaling levels are available at Fraunhofer ISE.

In the area of anode active material synthesis, we work with furnaces with different process atmospheres and temperature ranges. In addition, the active material can be scaled on our Piot line with up to 5 kg of material per day. Among other things, we use these facilities for research in the areas of silicon composite production for lithium-ion batteries and the synthesis of hard carbon, which is used as an anode active material for sodium-ion batteries.

At Fraunhofer ISE there are two different routes for the synthesis of the active cathode materials. In addition to the solid synthesis for layered oxides (e.g. NMC) for lithium-ion batteries, these active materials can also be produced by aqueous co-precipitation. Reactors with 2 L and 10 L are available in our laboratories for this purpose. The precursors produced by this process can be lithiated or sodiated by a subsequent high-temperature step. Research at Fraunhofer ISE ranges from the production of active materials for solid-state batteries (ASSB) to the synthesis of layered oxides for sodium-ion batteries.

Electrode Production via Solvent-Based and Dry Processing

Various processes and scaling options are available at Fraunhofer ISE for the development and production of electrodes.

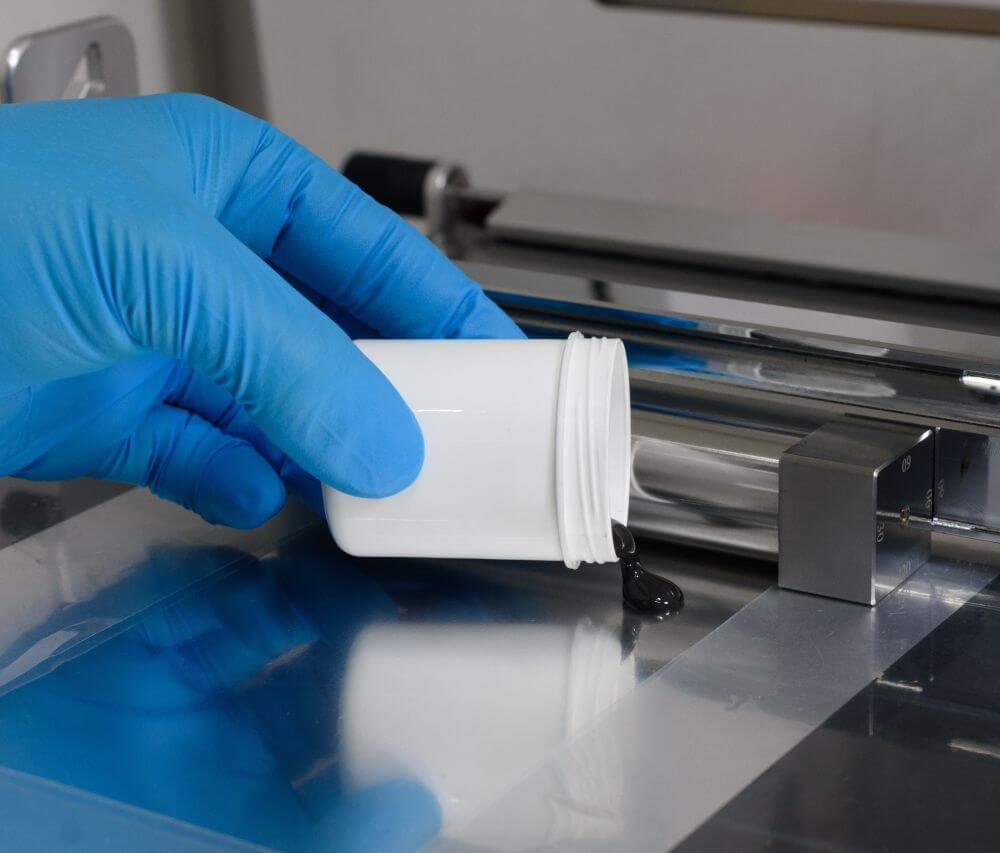

For the development and optimization of electrodes using a solvent-based process, we can use a laboratory-scale doctor blade process. After successful validation on a small scale, it is possible to examine the formulations on our roll-to-roll coater (available Q1/2025). Here we have the option of testing smaller quantities by doctor blade in a continuous process or evaluating substances for a further scaling step by slot die coating.

For dry or semi-dry electrode production, we have various options for pre-powder processing (e.g. ball mills and granulation). A discontinuous electrode production can be carried out both on a coin cell scale or in an application-oriented format (20 x 20 cm). In addition, we have the option of using a calender to process and evaluate a continuous dry coating.

In the area of solvent-based electrode production, we are researching, among other things, PFAS-free binder systems and the use of non-toxic solvents such as water. In the area of dry coating, we are investigating various process methods for powder pretreatment and are working with different binder systems.

Cell Assembly

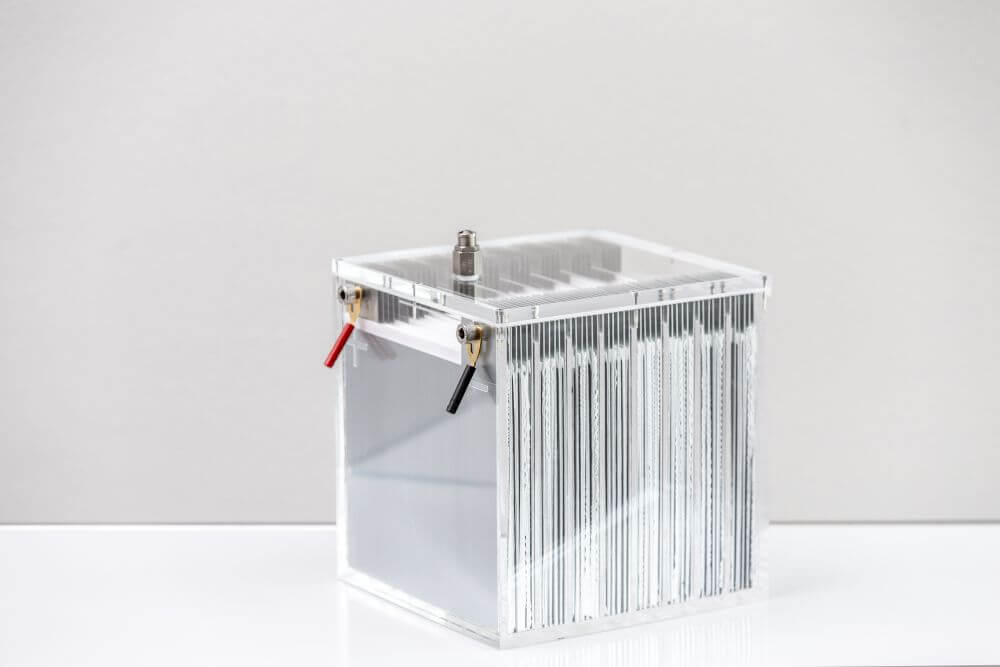

At Fraunhofer ISE, we can test materials and electrolytes in various cell formats:

- Experimental cell formats (e.g. coin cells, EL cells or Swagelok cells) are suitable for evaluating cell components during their development, for example. Cell types (EL cells or Swagelok cells) with a three-electrode setup allow, among other things, a precise determination of the redox potential. In addition, these cells can be opened so that post-mortem analyses of the components can be carried out.

- Single-layer and multi-layer pouch cells enable the testing of materials and other cell components in a scaled setup. These are assembled either in the glovebox or using semi-automatic production in the drying room.

- For the assembly of solid-state batteries, our gloveboxes are equipped with a wide range of processing equipment to scale up from experimental cells to pouch cells.

- For aqueous cell chemistries (e.g. zinc-ion technology), we design the cell housings ourselves according to requirements and print them using a 3D printer, among other things.

Electrochemical Characterization

Fraunhofer ISE has various options for electrochemical characterization:

- Characterization in half and full cell setups

- Development of formation strategies

- Galvano- and potentiostatic measurement methods (CC/CV and GITT measurements)

- Electrochemical impedance spectroscopy (EIS)

- Cyclovoltammetry (CV)

- Linear sweep voltammetry (LSV)

Dry Rooms and Mini-Environments

Manufacturing battery cells with innovative materials places high demands on the production environment. At the Fraunhofer ISE, the interplay between manufacturing technology and infrastructure as well as novel plant concepts are being investigated. Focusing on energy efficient clean and dry room technology, mini environments and contamination control, the following services are available:

- Evaluation of ventilation concepts for production facilities and mini-environments

- Evaluation of the efficiency of dehumidification systems and drying room concepts

- Investigation of infiltrations into the system technology

- Investigation of production technology, intralogistics and materials in mini-environments under varying ventilation concepts and inert gas, including particle emission control

- Mechanical material testing at different dew point temperatures (down to -55°Cdp)

- System and material testing in clean and dry rooms at different atmospheric conditions (dew point -30°Cdp to -55°Cdp)