We conduct safety tests on batteries and battery cells. In doing so, we can gain from extensive understanding of correlations and processes with the goal to design measures to optimize safety.

Safety tests on batteries

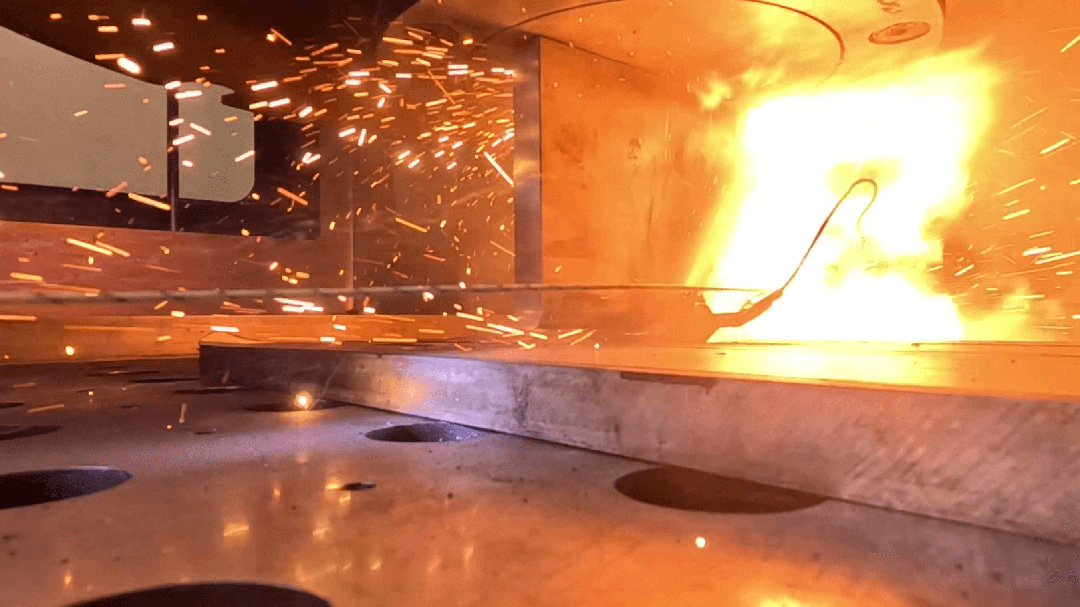

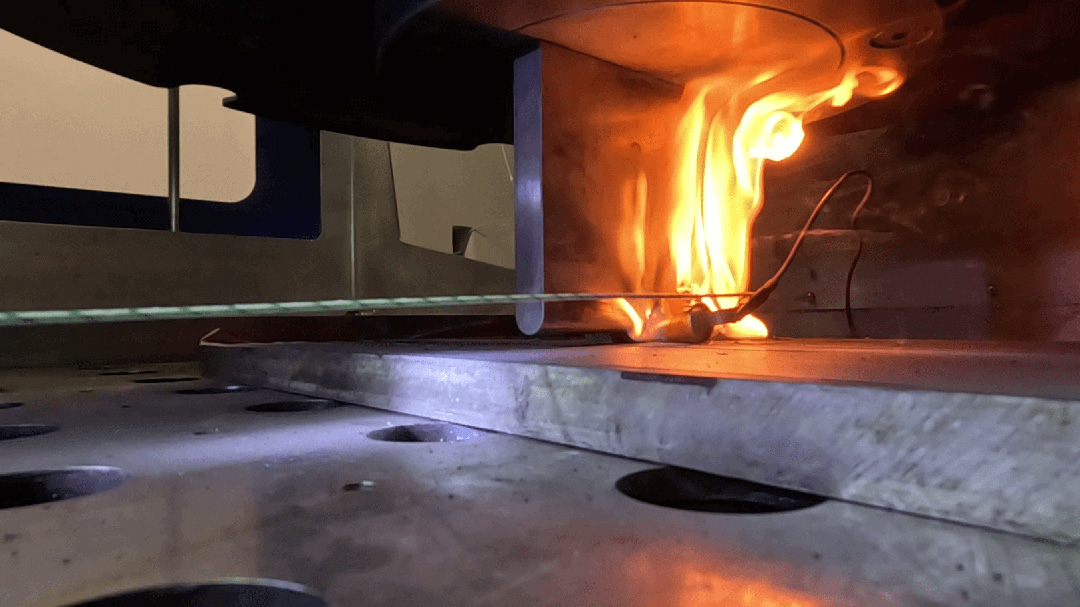

Experimental investigation is essential for understanding the safety of lithium-ion batteries. In our lab, batteries are brought into safety-critical states using various triggering methods. During and after these tests, a wide range of sensors are used to record data on factors such as temperature, voltage, pressure curves or gas development. These data allow us to determine the properties of safety-critical states and to develop countermeasures.

Crush tests: Destructive tests to optimize battery safety

Furthermore, we are investigating various scenarios that batteries are exposed to during their use. We are particularly focusing on situations that deviate from everyday use in line with the intended purpose. For example, a crush test can be used to test the penetration of a foreign body into a battery as well as the crushing and bending of a battery. Such tests can provide important information about battery behavior in accidents and in the event of improper handling. Battery safety is of crucial importance, especially when it comes to their use in electric vehicles. With our detailed analyses, we are able to provide valuable assistance in optimizing battery safety.