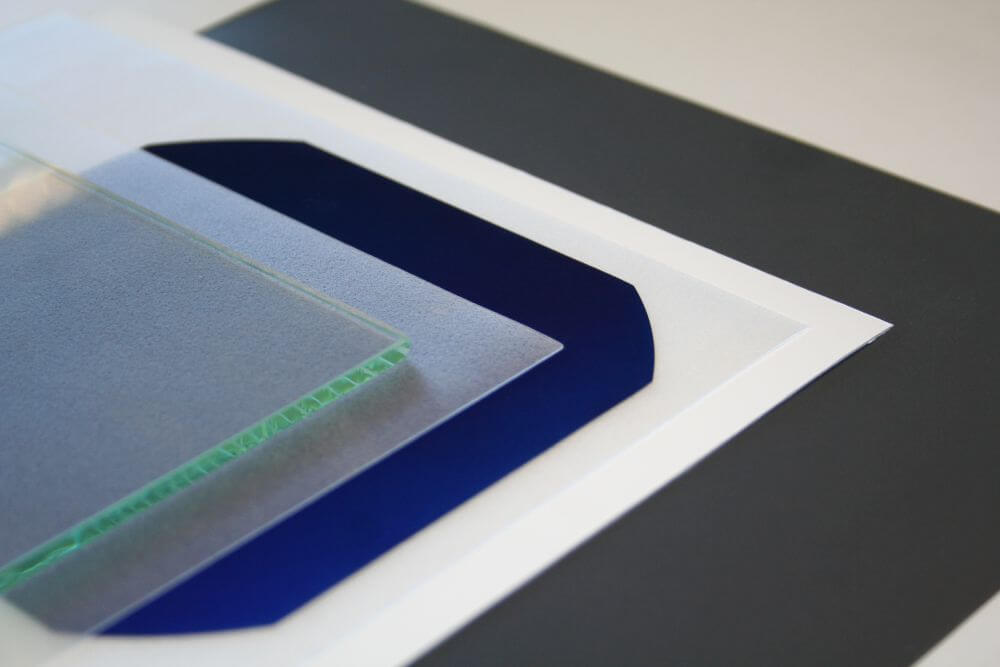

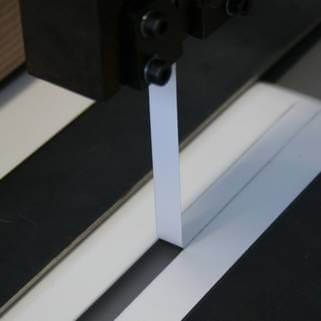

Encapsulation technology is used to protect the solar cells from environmental influences such as moisture, dirt and mechanical stress and to improve the optical and thermal performance as well as the reliability of the PV module. For this purpose, the cells are encapsulated in a transparent polymer between two glass plates or between a glass plate and a backsheet in the lamination process. The polymer melts under vacuum and high temperature and forms a stable bond with the cells.

There are various encapsulation technologies that can be used depending on the application and module type, such as glass-glass and glass-foil encapsulation, lightweight modules or 3D lamination. The choice of encapsulation materials and the optimization of the lamination process have an impact on lamination time, process costs, long-term stability and module performance. Fraunhofer ISE offers various services and research projects for the development and improvement of encapsulation technology.