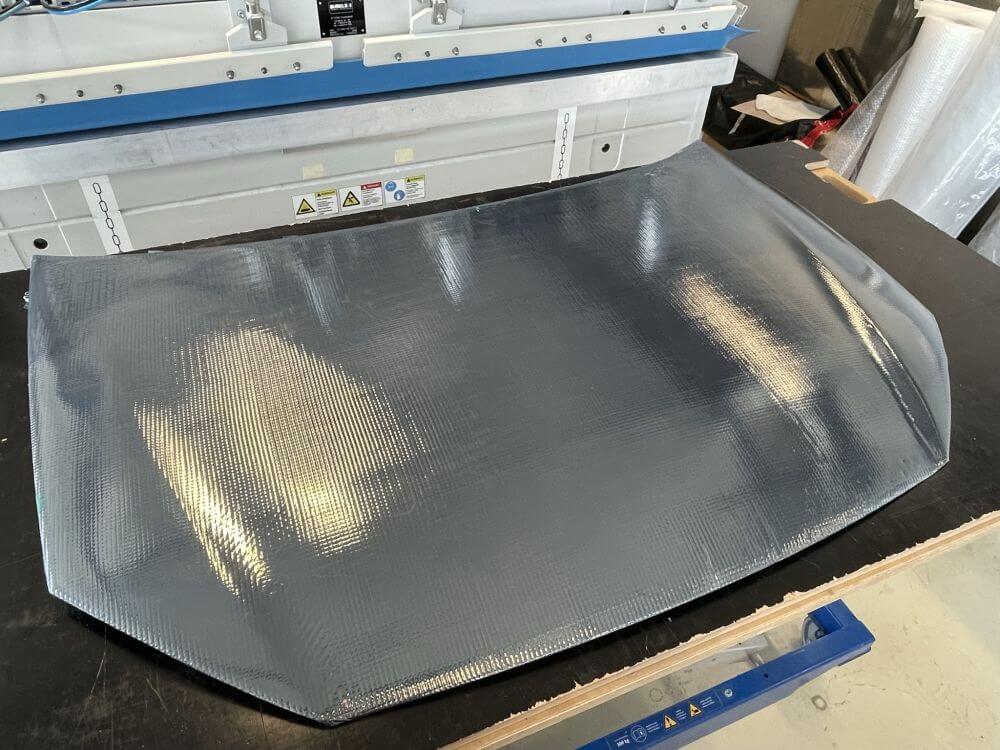

We offer solutions to problems and themes in the area of photovoltaics, solar thermal energy, energy efficiency, thin-film batteries and hydrogen technology based on the development of functional coatings. Our technical deposition process is focused mainly on sputtering..

Our range of services includes feasibility studies, small series production and product development through to finished industrial prototypes. We cover the entire spectrum of coating development, from the basics to demonstrator production and characterization of long-term durability.

We work together with companies that carry out coatings themselves, with plant manufacturers or with companies that use coated goods in their products.