With the help of simulation, physical processes such as the mass transport of media, taking diffusion and flow processes into account, as well as the course of chemical reactions, can be investigated and evaluated. Specific problems such as the mixing of chemical reactors or the diffusion of liquids and/or gases can be investigated and visualized in detail, making them suitable for applications in the process industry as well as in energy and environmental technology. Furthermore, chemical reactions in fluids as well as reactions at interfaces can be simulated. In combination with simulations of heat transport, the influence of the heat of reaction can also be integrated into the system.

Mass Transport and Chemical Reactions

R&D Services for Mass Transport and Chemical Reactions

In the research topic Silicon Photovoltaics, we offer the following services in the area of mass transfer and chemical reactions.

- Mapping of arbitrary components in a FEM model and calculation on a High Performance Computing Cluster (HPC cluster)

- Surface treatment of solar cells, heat pumps and heat and cold storage systems

- Optimization of reaction chambers including flow and heat distribution

- Virtual product development and optimization

- Spatially resolved modeling of surface reactions

- Experimental validation

Application Examples

Rounding of Micropyramids

In the photovoltaic industry, wet chemical baths are used for surface structuring, conditioning and cleaning. In addition to cleaning the wafers, surface etch removal also occurs during ozone-based wet chemical cleaning processes, resulting in two effects: The etching back of the emitter as well as the rounding of textured surfaces. To simulate and predict these roundings of micropyramids during the cleaning process, a two-dimensional process simulation model was built to describe the diffusive and convective mass transport of ozone along the pyramids. Important parameters for the evaluation, which are derived from experimental results, are the etch rate and the resulting roundness (R) of the micropyramid tips. A parameter study was performed to fit the model. The simulation represents the experimental data very well, after 2 min exposure R = 67 nm for the experimental and R = 66 nm for the simulation data.

Brief Description:

- Goal

- Improvement of the passivation quality by rounding of pyramid tips on textured solar cells

- Simulative illustration of the rounding process on micro-pyramids

- Procedure

- 2D simulation with stationary flow in the gap by Navier-Stokes and continuity equation

- In combination with mass transports in the domain and at the wafer surface

- Deformation of the computational mesh with time represents etch removal at the wafer surface

- Validation of the simulation with experimental results

- Result

- Model for the prediction of the rounding radii at different process parameters

Mesh deformation can be used to show the rounding of the pyramids as a function of diffusion- and convection-based mass transport of the reactants with time.

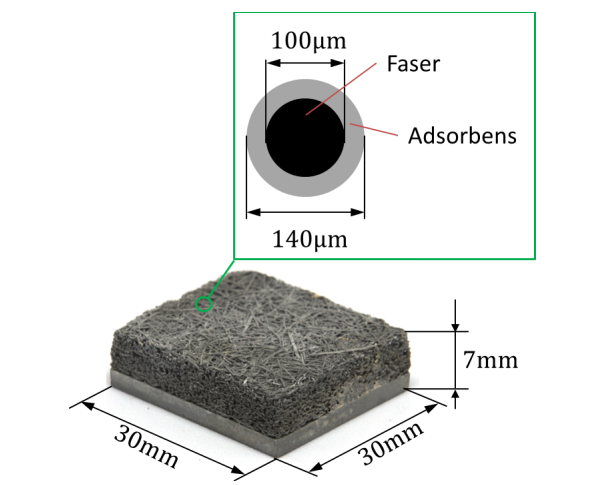

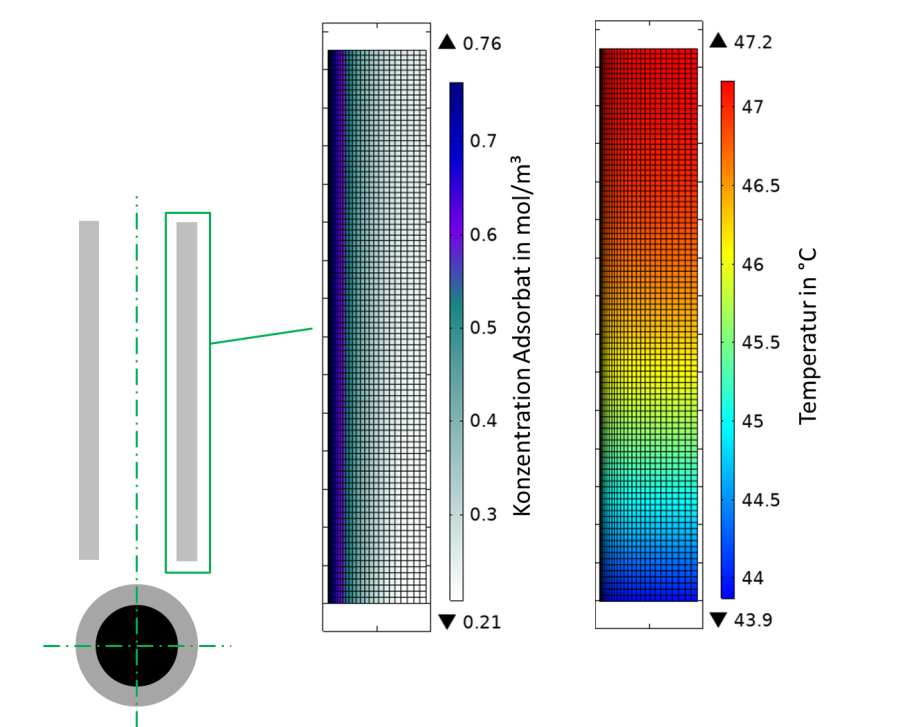

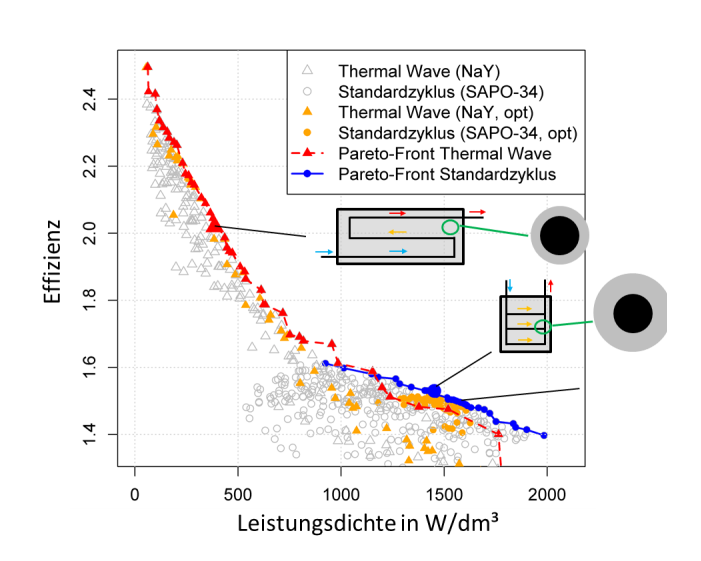

Adsorption of Water Vapor in Microporous Adsorbents

Building air conditioning and the need for domestic hot water account for a significant share of energy consumption in private households. Likewise, there is a large demand for cooling in data centers, for example. Thermally driven heat pumps can help reduce energy consumption here. Adsorption heat pumps and chillers use microporous adsorbents that release heat while absorbing water vapor. To achieve a high power density of the adsorption heat pump or chiller, it is crucial that the heat and mass transfer processes in the components take place as quickly as possible. At the same time, it is important for high efficiency that the thermal mass of the components is as low as possible. A promising design for adsorption heat exchangers are fiber structures with a large surface area (8000-12000 m²/m³) coated with a microporous adsorbent. An understanding of the coupled heat and mass transfer processes is required to design this type of heat exchanger.

Brief Description:

- Goal

- Predicting the dynamics of coupled heat and mass transfer in fiber structures coated with a microporous adsorbent

- Design of adsorption heat exchangers based on coated fiber structures

- Calculation of efficiency and power density in an adsorption heat pump or chiller

- Procedure

- Simulation of mass transfer on two levels:

- At the macro level, water vapor flows through structural pores in the order of 80-200 µm, here 1D simulation viscous flow or Knudsen diffusion

- At micro level, adsorbed water diffuses in the compact adsorbent layer, here 2D simulation of adsorbate diffusion

- 1D and 2D model coupled by source and sink terms for heat and mass transport

- Validation of the simulation with experimental results

- Result

- The model for the design of adsorption heat exchangers can be used to calculate the efficiency and power density of adsorption heat pumps and chillers

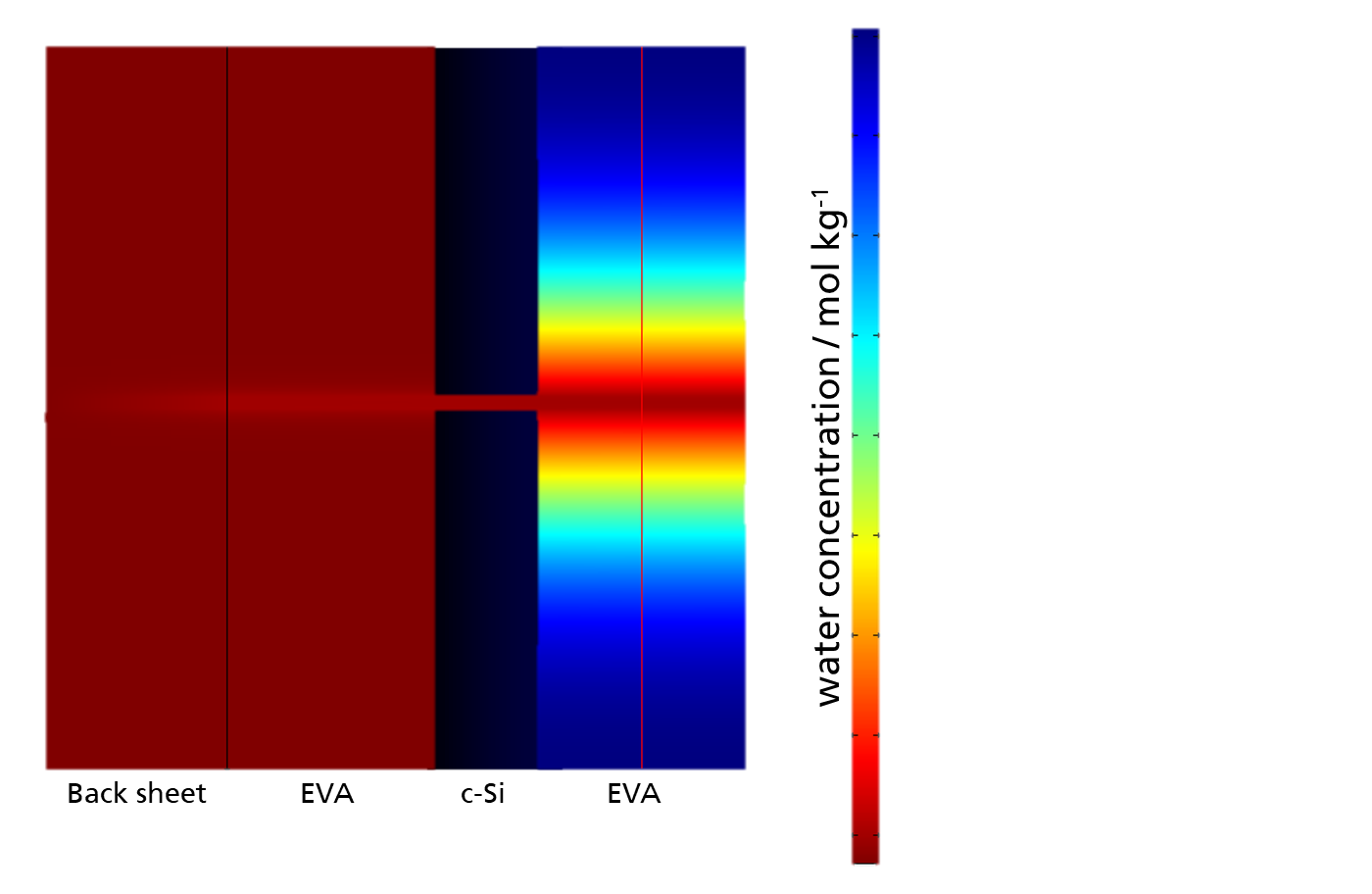

Simulation of the Microclimate

All parts and components (such as PV modules, cables, solar thermal collectors, etc.) that are used outdoors are exposed to influences that usually result in aging. The decisive factor for the aging processes is the microclimate in the component or components, which can sometimes differ significantly from the measurable macroclimate (ambient temperature, relative humidity). Especially for special geometries, the microclimate is difficult to measure, but can be reliably described by FEM simulations. The input variables are temperature, relative humidity and material-specific parameters such as permeability or mass transfer coefficients, thermal conductivity and density, which can be measured in our Center for Material Characterization and Durability Analysis. In the example shown here, the moisture balance within a PV module consisting of backsheet, EVA, silicon cell and cover glass (not shown) was simulated during a steam-heat test. The determined water concentrations can then be used in the development of accelerated aging tests.

Brief Description:

- Goal

- Simulation of the moisture balance of components as a function of climate data

- Procedure

- Measurement of relevant material parameters like diffusion coefficients, thermal conductivity and adsorption isotherms

- Transfer of the component geometry into a representative section for the simulation

- Extraction of relevant temperature and humidity curves from monitoring data or models

- Simulation of the moisture balance of individual materials over time

- Analogously, it is possible to simulate other species such as oxygen or acetic acid

- Result

- Microclimate in the component in the form of temperature and humidity for an application-oriented derivation of tests for the reliability of components