The metallization of solar cells is one of the largest cost factors in the manufacturing process. It has a significant influence on both cell efficiency and module connection.

While silver is still the main contact material used in production, we at Fraunhofer ISE have been developing alternative manufacturing processes based on copper for many years. This saves costs, achieves the same solar cell efficiencies and ensures the availability of the required materials even in the rapidly growing photovoltaic market.

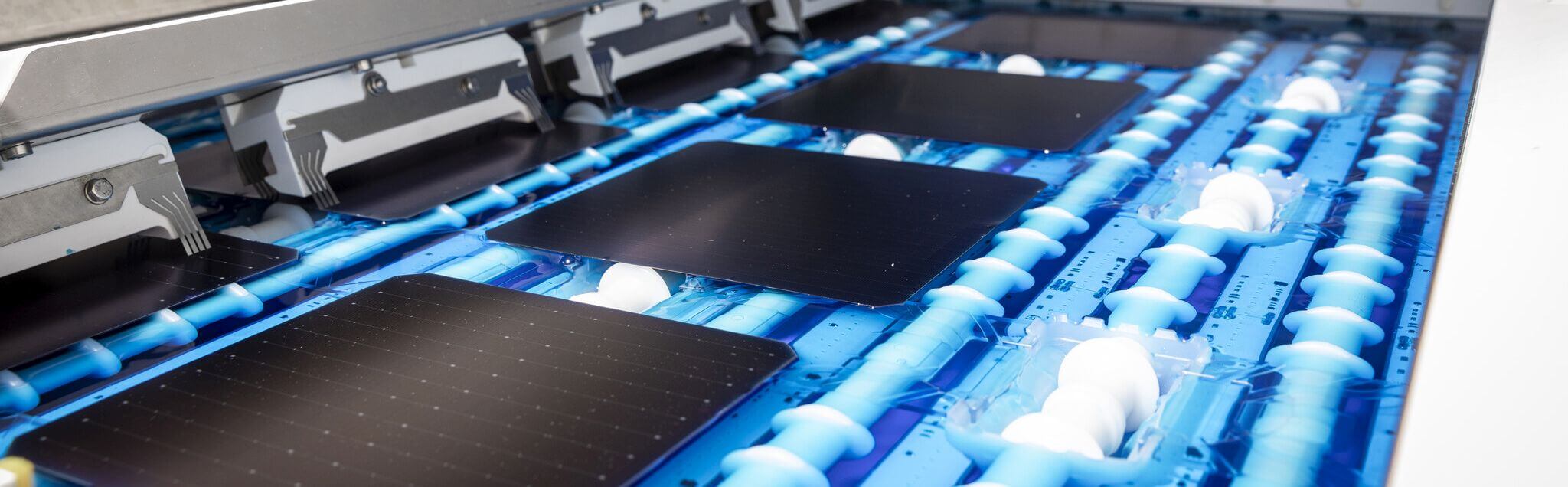

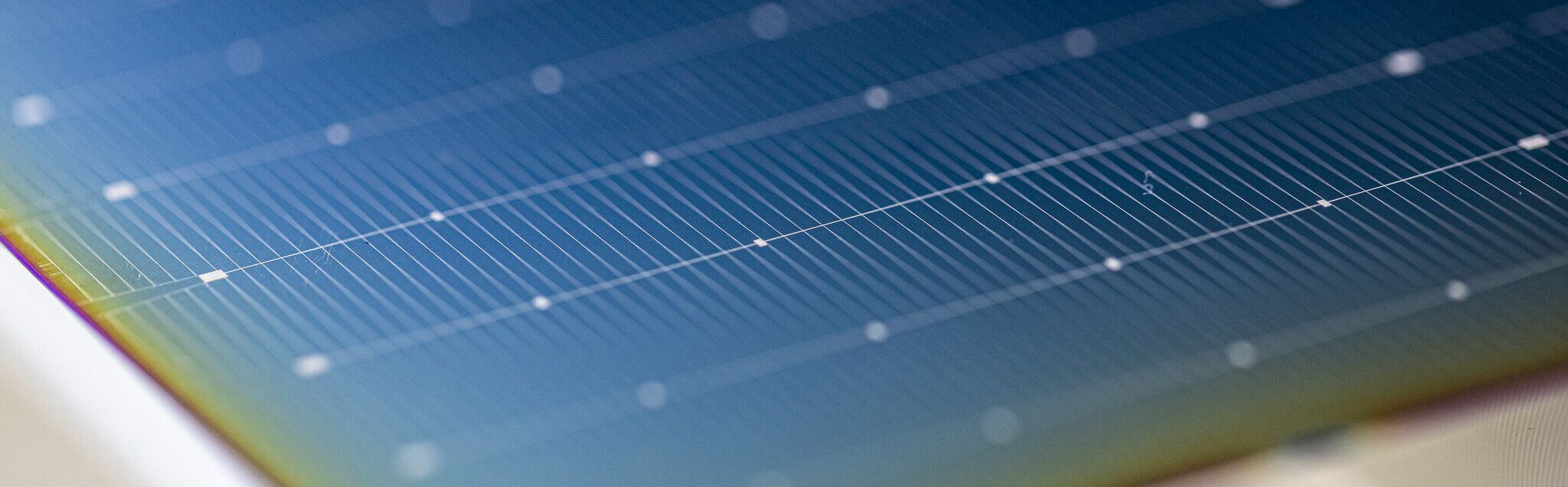

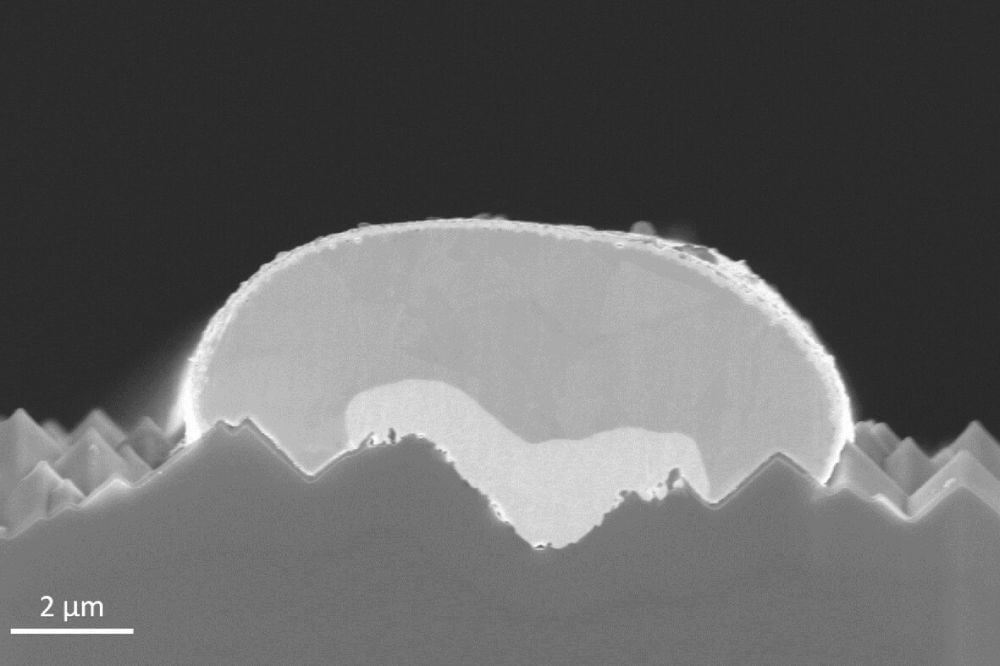

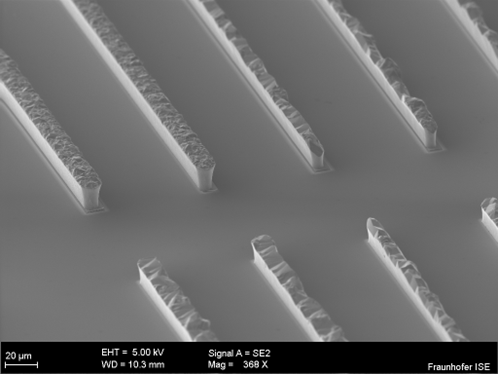

We develop galvanic metallization processes for various types of solar cells. Laser structuring of the anti-reflective layer is used for both TOPCon and PERC solar cells, and a layer stack of nickel, copper and an ultra-thin silver finish is then deposited from the chemical solution.

For silicon heterojunction and perovskite solar cells, special measures are required to avoid deposition over the entire surface of the transparent, conductive oxide. At the same time, sensitive functional layers must be protected from corrosion by the galvanic baths. We have developed innovative solutions to realize galvanic copper contacts for these challenging applications as well.

Even on III-V or germanium materials, galvanic metal processes are interesting alternatives for highly conductive and cost-efficient contacts. Even though material costs usually play a less important role here, galvanic metal deposition also allows for very high-performance metal contacts under economic conditions. .