Individualized productions such as those in the Photovoltaic Technology Evaluation Center (PV-TEC), ), place high demands on the flexibility of software systems for production monitoring and the collection, interlinking and analysis of the resulting data due to the wide variety of manufactured products and the continuous change in production capabilities and processes. Conventional production control systems can only cope with this to a limited extent, due to the need to adapt operating processes to these systems and the considerable configuration and maintenance effort involved.

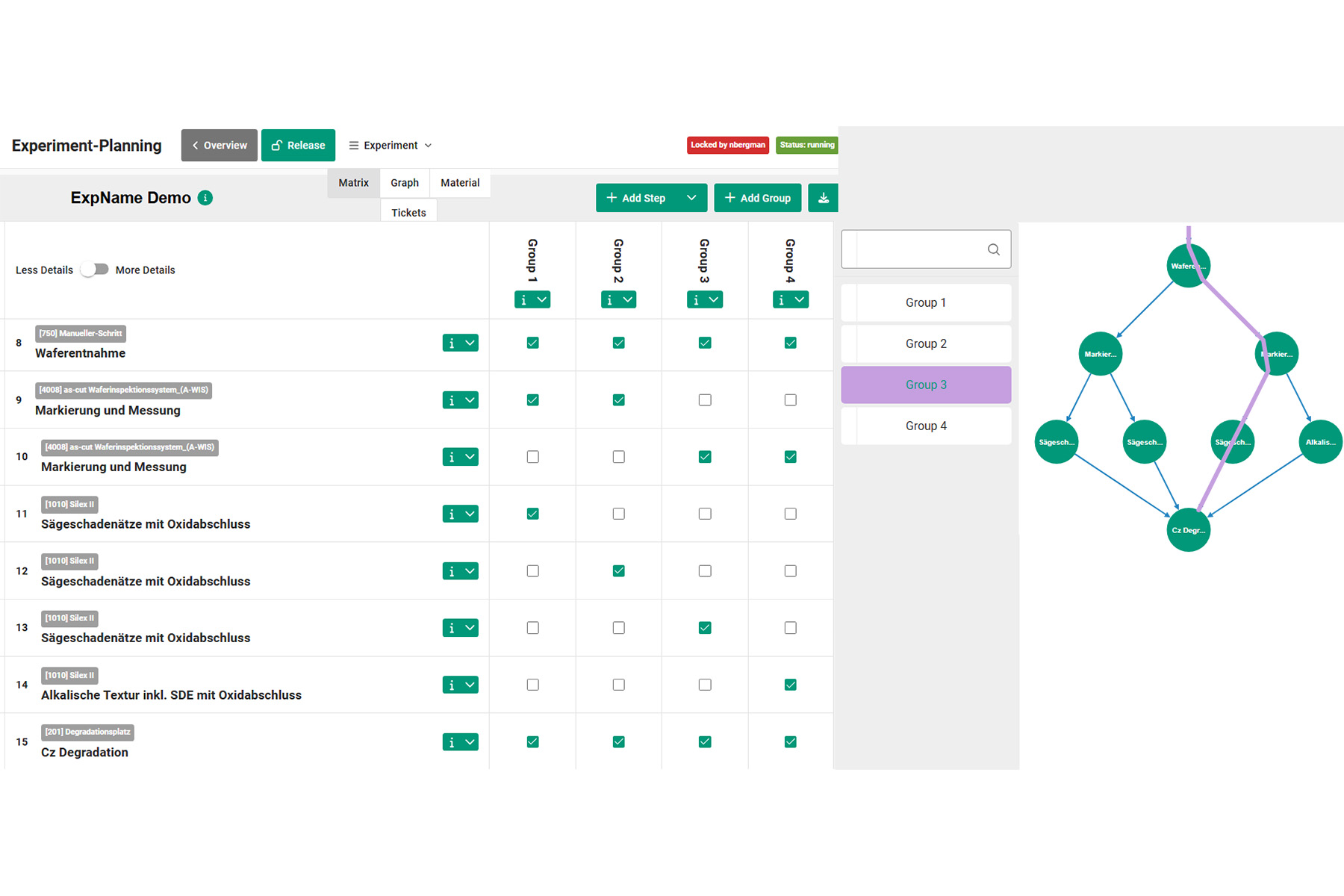

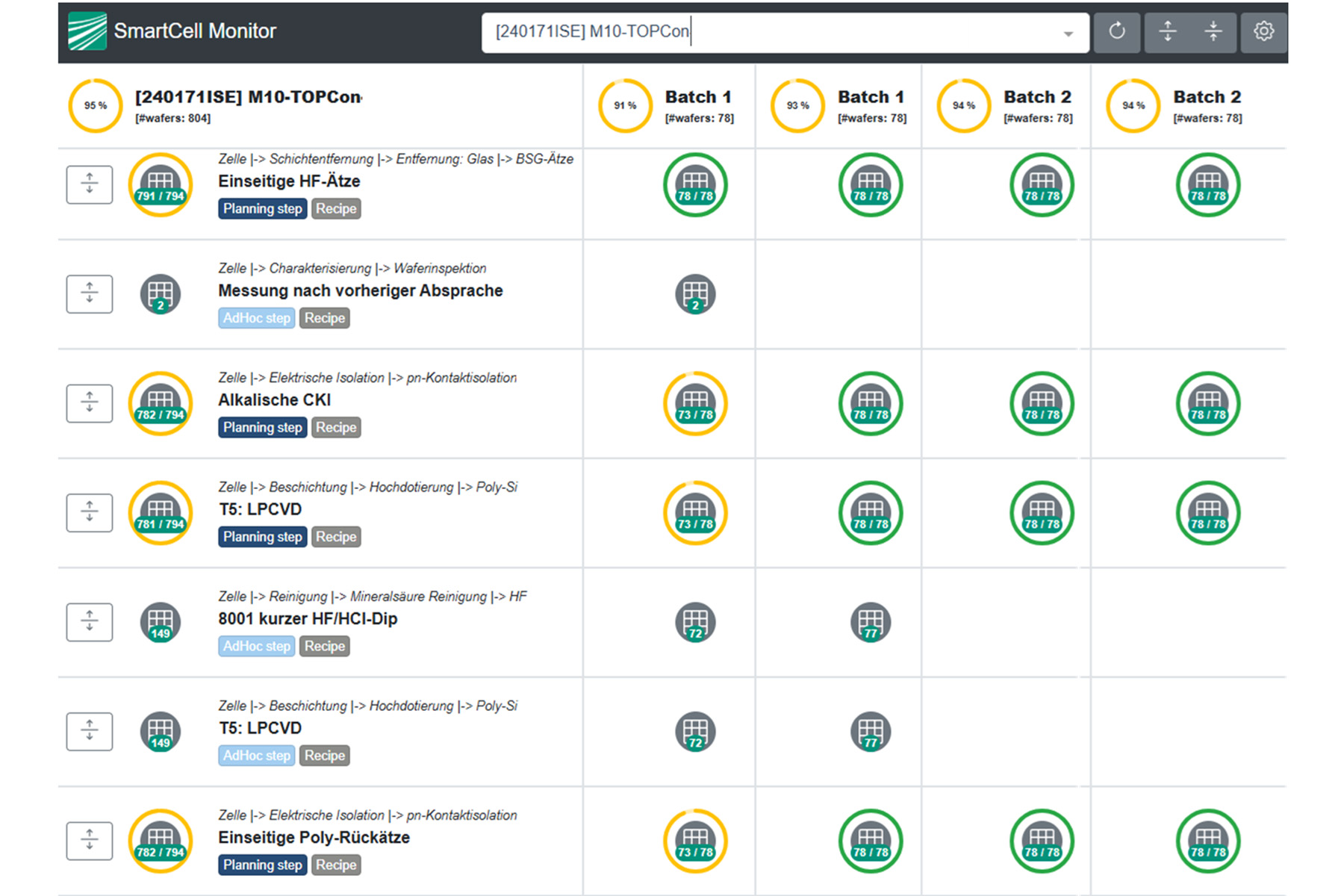

We therefore develop innovative modular digitalization concepts for planning and tracking production orders and collecting and analysing the resulting data, which meet the requirements of individualized productions. In addition to the selection and implementation of suitable NoSQL databases and the development of customized metadata models we develop specific applications for master data management, material management, experiment planning and order tracking as well as for data acquisition, data filtering, data analysis and dynamic report generation. In doing so, we attach importance to an open and easy-to-use interface to the database network, which enables the customer to connect their own analysis and reporting tools to the system with little effort.

Our "SmartCell" software solution is characterized by:

- a scalable, micro-service-based software architecture

- a container-based software implementation and the use of a modern development & operations (DevOps) platform that ensures CI/CD (continuous integration, delivery & deployment) and thus short development cycles

- provision of a uniform "single source of truth" data interface for all applications

The system is therefore easy to expand, efficient to administer and variable to integrate. We ensure code quality through the use of professional development and operation strategies. Our software ECO system thus fulfills the essential requirements for productive use in an industrial environment and is successfully used in the PV-TEC laboratory of Fraunhofer ISE.