During coating development, we use various characterization methods, such as optical, structural, chemical or electrochemical analysis. Based on this, we offer our customers services for the characterization, analysis and measurement of functional surfaces. We adapt our analyses to their individual requirements.

Lab Characterization of Functional Surfaces

Our Services in the "Lab Characterization of Functional Surfaces" Include:

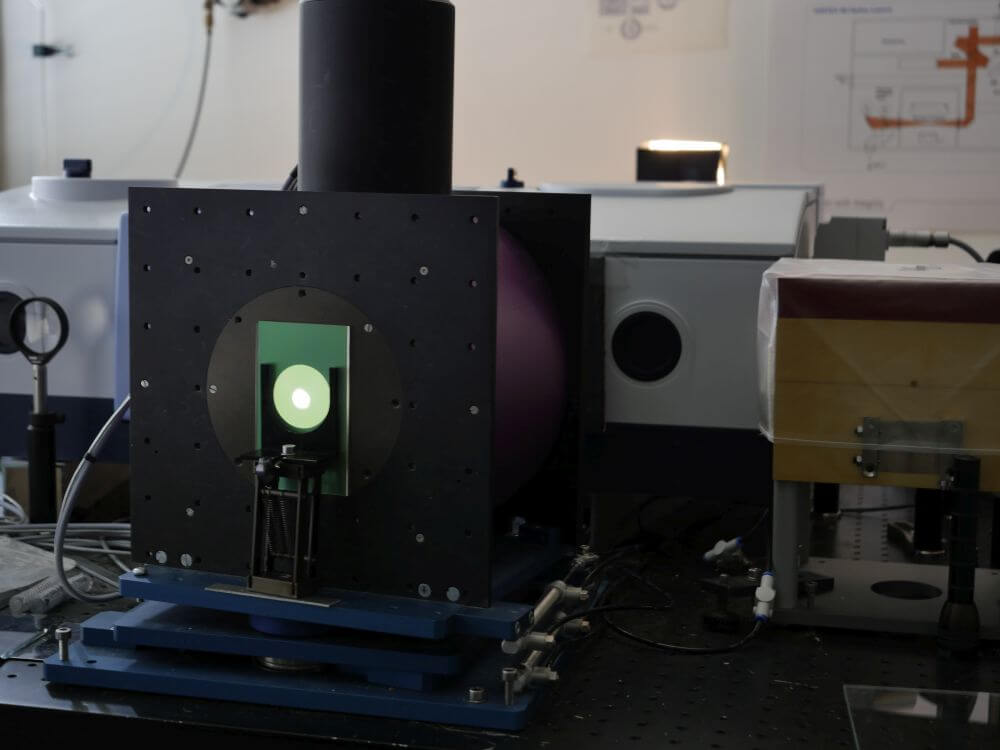

Optical Characterization

The measurement of the spectral hemispherical reflection, transmission and absorption of samples and products in the Fourier transform spectrometer is the basis of our work in the development of optical coatings. However, we also offer these services to customers and can thus answer individual questions.

The measurements are carried out in the Fourier transform spectrometer, which has an integrating sphere for measurements in the short-wave spectral range (300 nm - 2.4 µm) and a sphere for measurements in the infrared spectral range (1.9 µm - 17 µm).

By weighted integration of the spectra with e.g. the solar spectrum AM 1.5 according to ASTM G173 or the Planck radiator at a temperature to be agreed, integral parameters (e.g. solar transmission, absorption, thermal emission) are calculated.

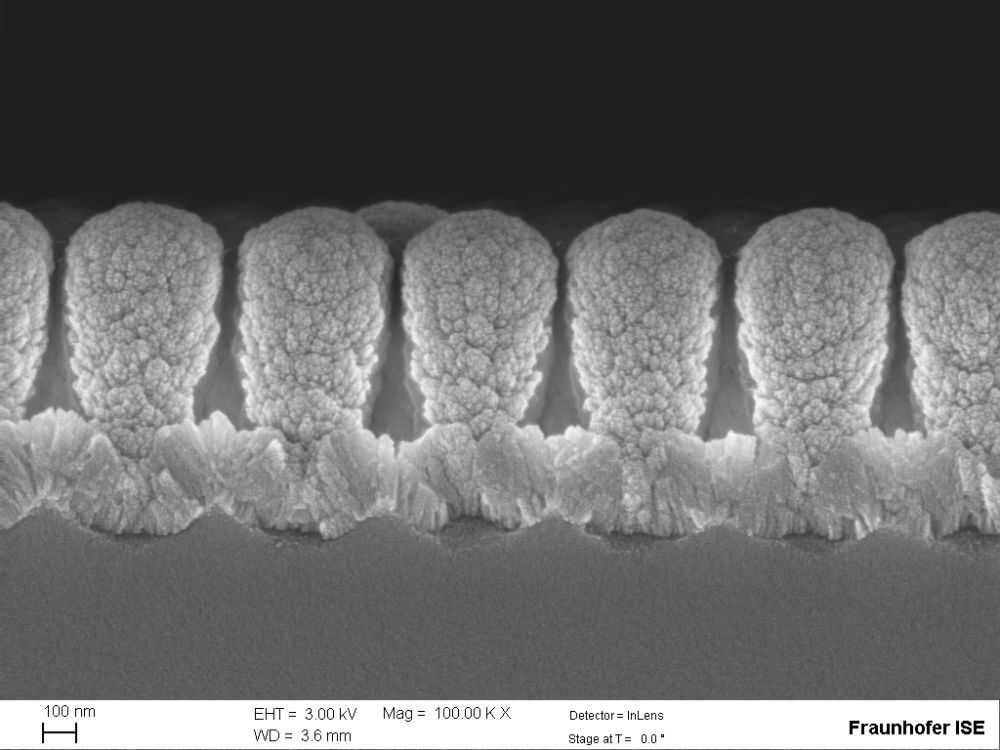

Characterization of the Structure or Microstructure

To characterize the structure and microstructure of surfaces, we have various microscopes available for different magnifications and research questions. Larger structures can be easily depicted and evaluated with regard to the common roughness parameters using a light microscope and a white-light interference microscope. Roughness in the nanometer range can be examined using an atomic force microscope.

Structures of a few nanometers can be made visible using a scanning electron microscope (SEM). In addition, connected EDX (energy dispersive X-ray spectroscopy) can be used to analyze the material composition, either at individual points or in the complete image section (mapping).

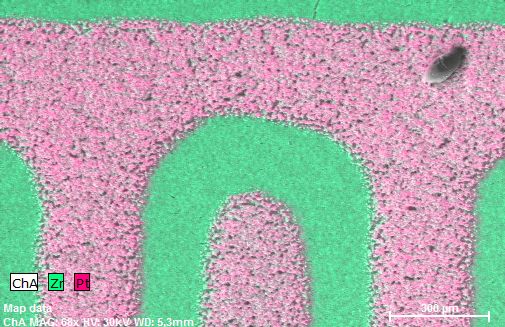

Analysis of the Material Composition (Chemical Characterization)

An EDX (energy-dispersive X-ray spectroscopy) connected to the scanning electron microscope (SEM) provides us with information about the material composition of samples. In addition to point analyses, complete image sections can also be displayed (mapping).

Our X-ray fluorescence analysis (XRF) offers a quick measurement of the material composition of individual samples. However, only elements with an atomic number above 11 can be detected here.

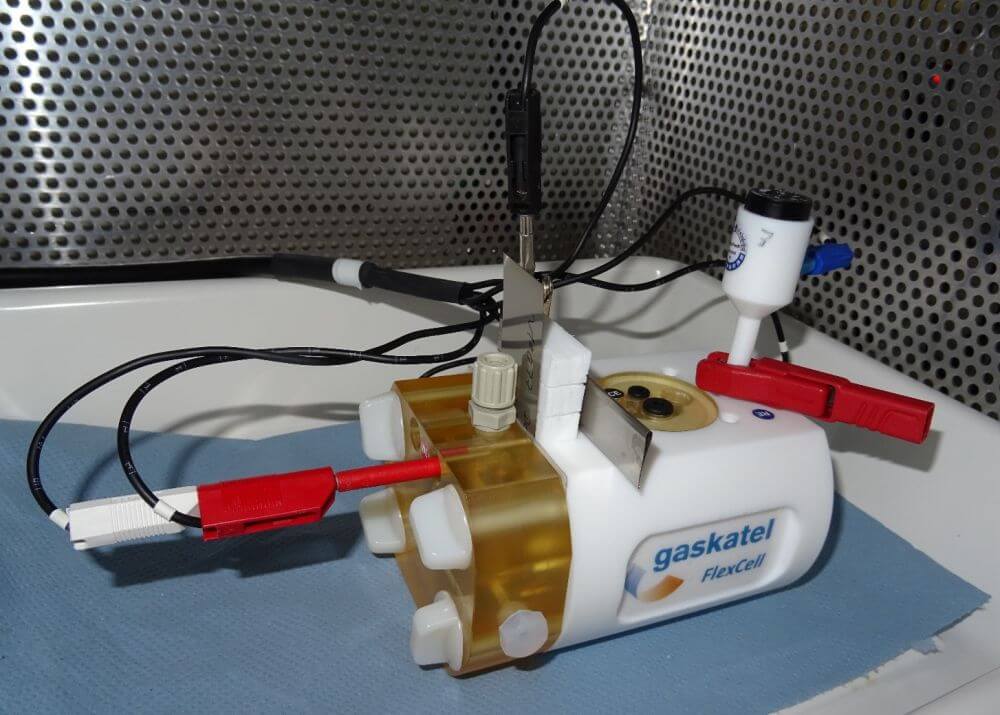

Electrochemical Measurement Methods

Corrosion protection coatings for bipolar plates and porous transport layers (PTL) are used for PEM electrolysis and PEM fuel cells. The BTS group offers the possibility of intensive electrochemical characterization of the corrosion resistance of such layers by means of ex-situ measurement protocols in three-electrode test cells. This is done in combination with measurement of the contact resistance and trace analysis of the electrolyte (ICP-MS). The electrochemical methods include impedance spectroscopy, cyclic voltammetry, linear sweep voltammetry, chronoamperometry and Mott-Schottky analyses. Depending on the application, specific test protocols and test electrolytes are used.

For electrochromic optically switchable systems, electrochemical methods are combined with optical measurement. In particular, the BTS group has also developed characterization methods for photoelectrochromic and photochromic systems.

Layer Stresses in Thin Layers

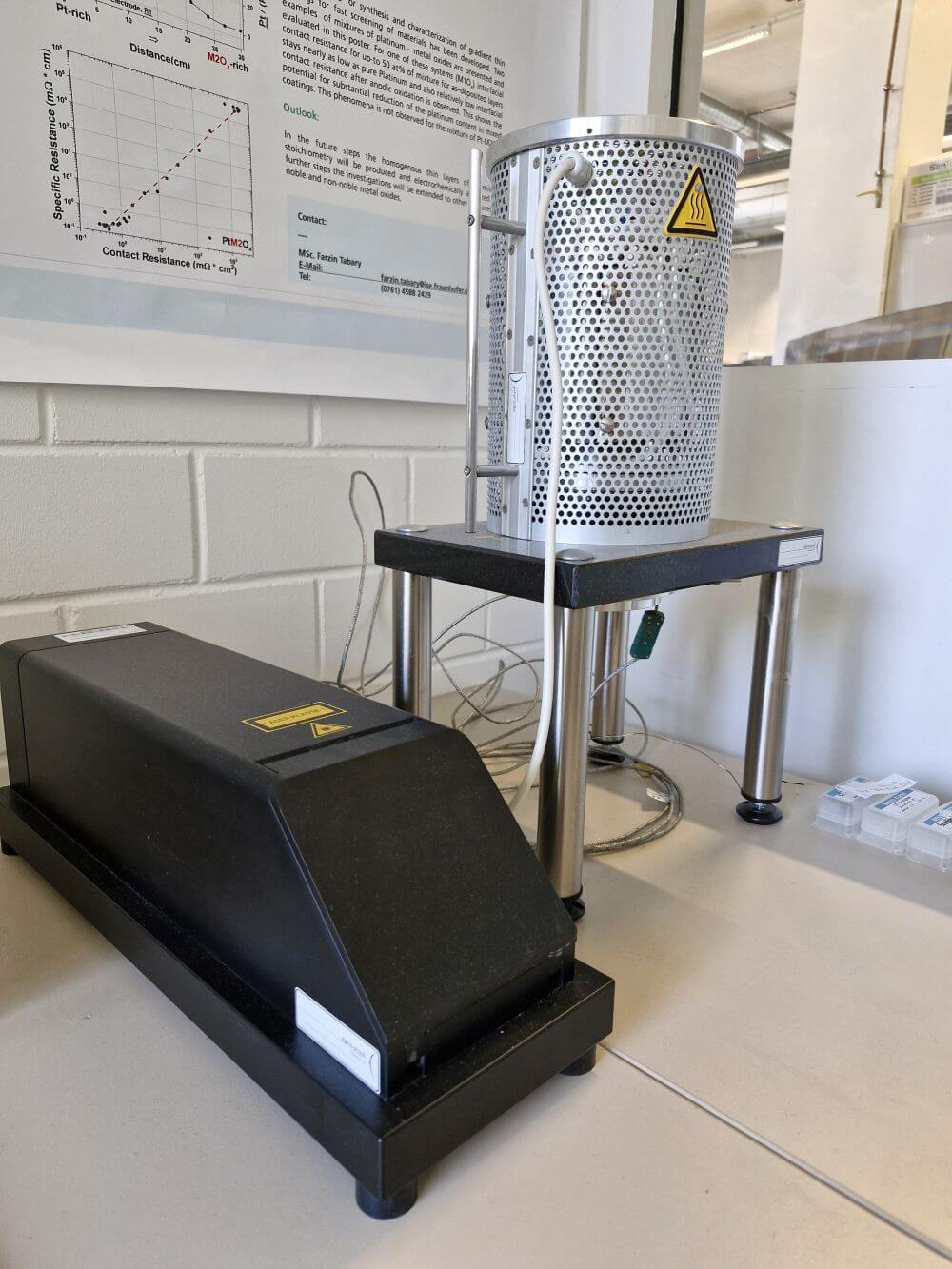

Excessive layer stresses in thin layers can lead to cracks or even delamination, which is particularly interesting in multi-layer coating systems. In the stress measurement system, the curvature of thin glass substrates or silicon wafers due to mechanical intrinsic stresses in the layer is measured by laser; the mechanical layer stress can be determined from this. The process parameters during the sputtering process have an influence on the level of mechanical stresses and can be optimized using these measurements.

An extension of the measuring system enables the determination of thermally induced layer stresses. For this purpose, the coated glass or silicon samples are heated and measured during this process.

Resistance Tests

To investigate the resistance of our coating developments, we define resistance tests at the start of development that characterize the application conditions of the products as well as possible. We have various ovens in different sizes and different maximum temperatures (up to 1000°C) at our disposal for this purpose. The samples can be exposed to different environmental conditions, e.g. air, vacuum, various gases.

We also have two climate chambers in which we can expose samples to different temperatures and humidity levels (e.g. vapor heat test) and carry out condensation tests. Weathering with UV radiation is also possible.

To evaluate mechanical resistance, we have an abrasion test stand based on the structure for coated glass panes described in the DIN EN1096-2 standard. It enables cyclic tests with a standardized piece of felt, in which the number of cycles and the length of the abraded surface can be set. In addition, harder material can be used as an alternative to felt.