Generative AI models offer the potential to significantly improve the quality of measurement data or accelerate the generation of simulated data. Using an extensive database, the models learn to process the structures in the data in a task-specific manner. We train generative models for our metrology and production partners, which, for example, increase the resolution of the measurement or calculate out the blurring in images of moving samples. This speeds up measurements and simulations, reduces the costs of measurement systems and quantifies even the smallest structures in low-resolution measurements.

Generative AI Models and Transfer Learning for Data and Measurement Technology Optimization

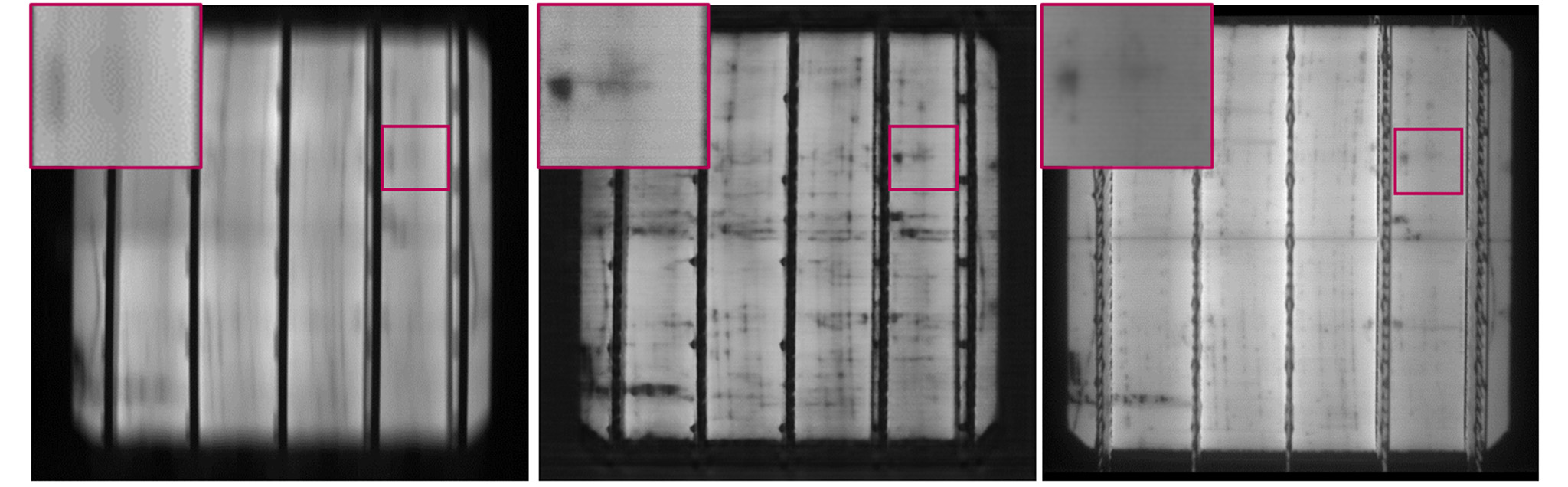

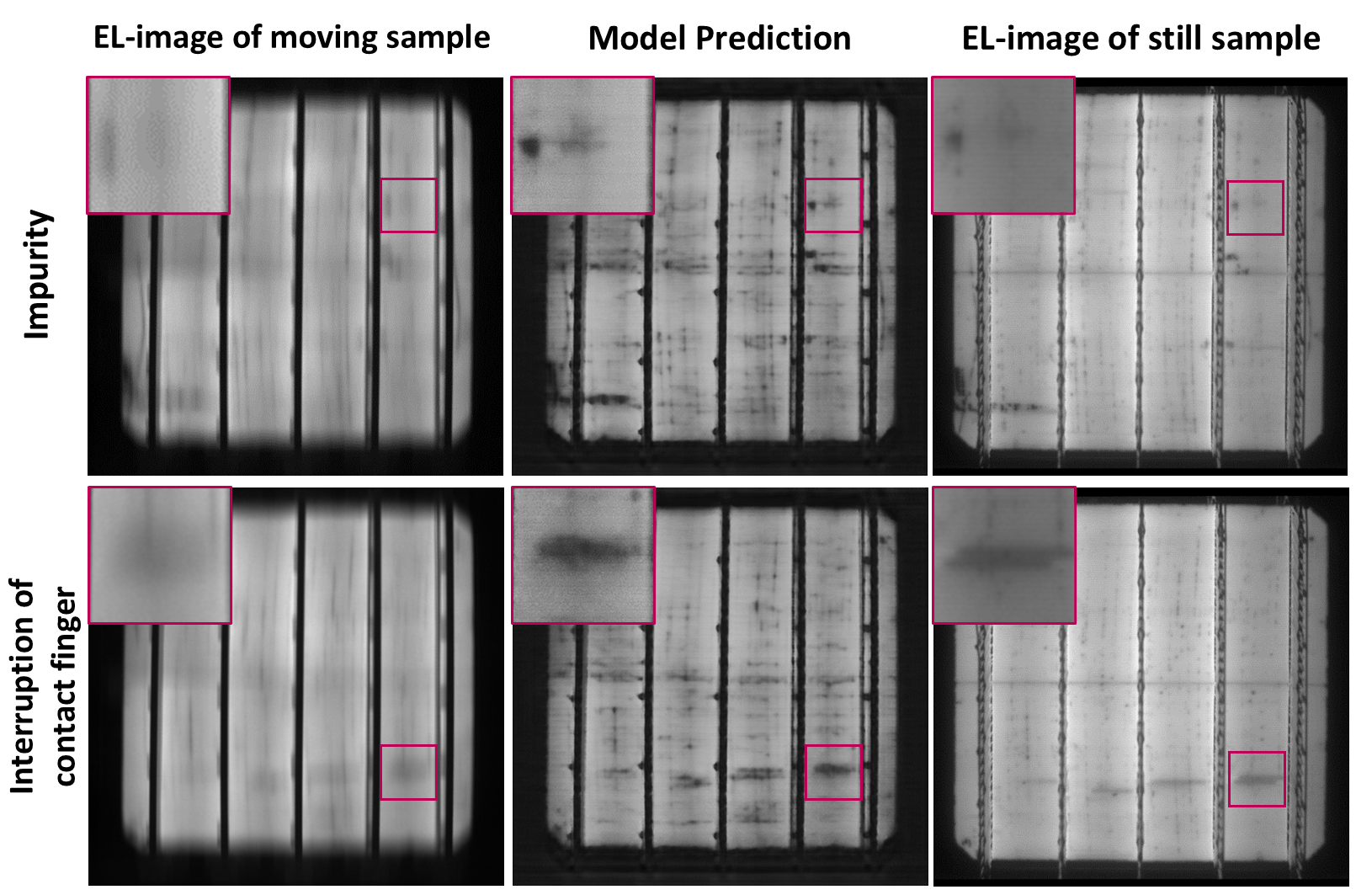

Defect Detection in Measurements on Samples in Motion

Center: The generative AI model learns to correct this blurring.

Right: The generative AI model recreates the defects analogous to the reference measurement on the stationary sample.

We are pursuing innovative approaches for the high-throughput inspection of solar cells. Electroluminescence measurements can be accelerated by capturing the sample in motion. This is where conventional algorithms for defect detection fail due to the motion blur in the images. We have developed two solutions for this:

- Our generative AI models are able to correct the blurred images and make the defects visible. The models are first trained using synthesized data and then transferred to the real measurement data. Despite the noisy signal, the image is reconstructed and can then be evaluated by humans.

- The defects can even be detected directly in the blurred images by our AI models. Our "smart labeling" approach is used here, in which extensive data with defect information is collected using reference measurements, in particular series resistance defects (such as finger interruptions) or defects in the dark saturation current (such as material defects). This information is used as a label to train the detection models.

By applying deep generative AI models and the smart labeling approach, the challenges of motion blur can be overcome. Our methods allow the algorithms to be quickly adapted to our customers' production lines and measuring systems (Figure 1).

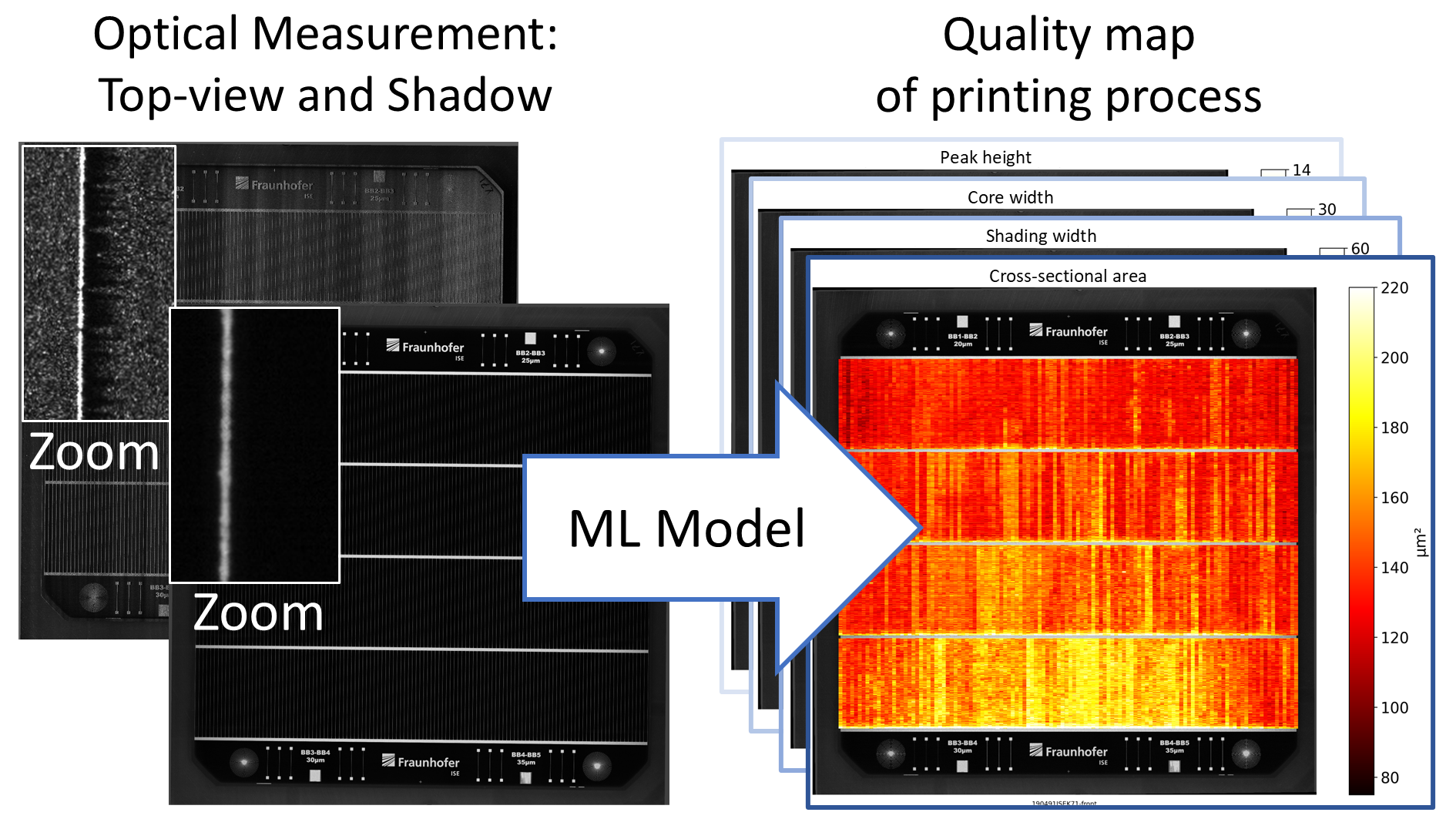

Full-Surface Analysis of Smallest Geometric Structures

In addition, we are developing AI models that enable the geometric analysis of printed structures on a microscopic level based on full-area measurements during production. Using deep learning methods, geometric parameters of the contact structures on the solar cells are extracted from optical inline images, which are crucial for monitoring and optimizing metallization technologies. In particular, the shadow cast by a laser beam incident at a flat angle is reliably evaluated in order to determine the height of the structures. This technique replaces traditional, time-consuming microscopic measurements and enables fast and comprehensive quality control of the entire printed structure.

Our R&D services include:

- development of high-throughput measurement methods through AI-based optimization of measurements on samples in motion:

- application example: evaluation methods for "on-the-fly" electroluminescence measurements, which enable a significant reduction in measurement times.

- development of AI models for defect identification or structural analysis in noisy or low-resolution measurements

- application example: defect detection in fuzzy electroluminescence measurements due to sample movement

- application example: geometric analysis of printed structures for full-surface print characterization based on production data

- smart labeling: customer-specific data generation using smart labeling technology for fast and precise defect annotation based on reference measurements

- improving image quality with synthetic data: developing methods to artificially generate motion blur and camera noise to create larger data sets for the training of defect detection models