We analyze battery components using modern analytical methods and characterization equipment to support our customers in process and product development. Our services are aimed at companies and research institutes that develop and manufacture batteries and electrical storage systems.

One of our core competencies is the performance of post-mortem analysis of battery cells. For example, by analyzing cell components, we identify the causes of performance problems or failures. These studies are critical to improving the safety and lifetime of battery cells.

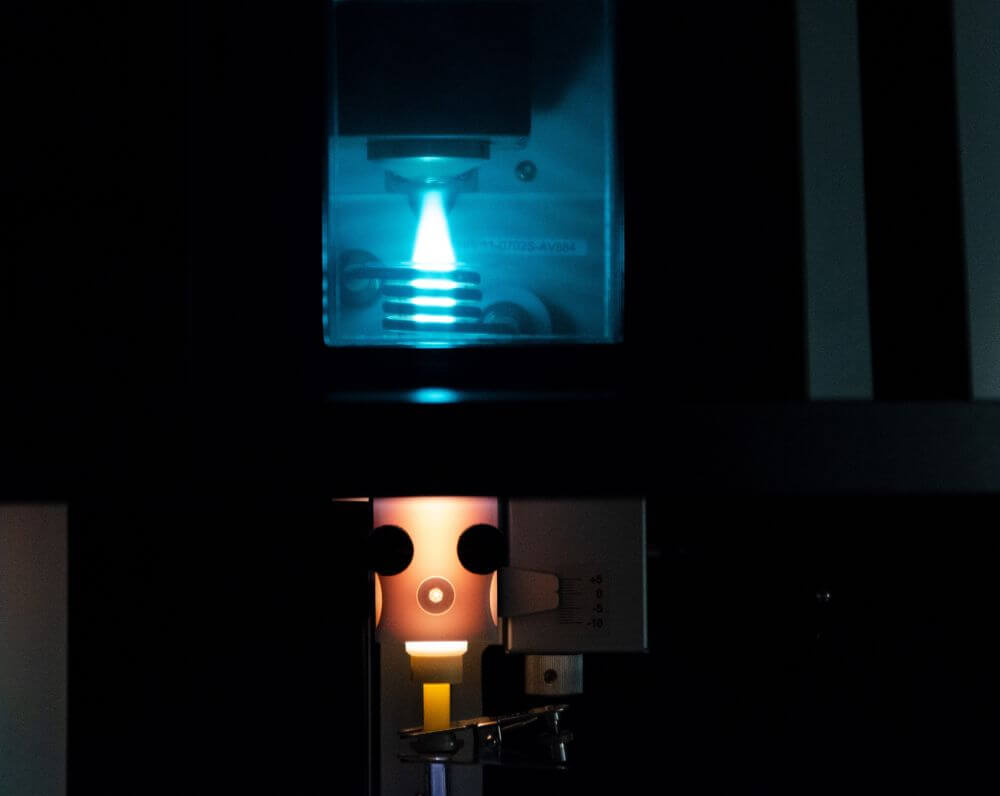

Our laboratories are equipped with a wide range of analytical methods that allow us to perform detailed and precise investigations. In addition, our interdisciplinary team has many years of experience in battery material characterization.