Efficient and reliable detection of malfunctions and energy losses is essential for reducing costs and guaranteeing successful operation. By promptly identifying issues, timely corrective actions can be taken to minimize downtime and maintain optimal performance. This proactive approach helps to extend the lifespan of the PV system, maximize energy production, and ultimately increase return on investment for solar energy projects.

PV Systems Performance Monitoring

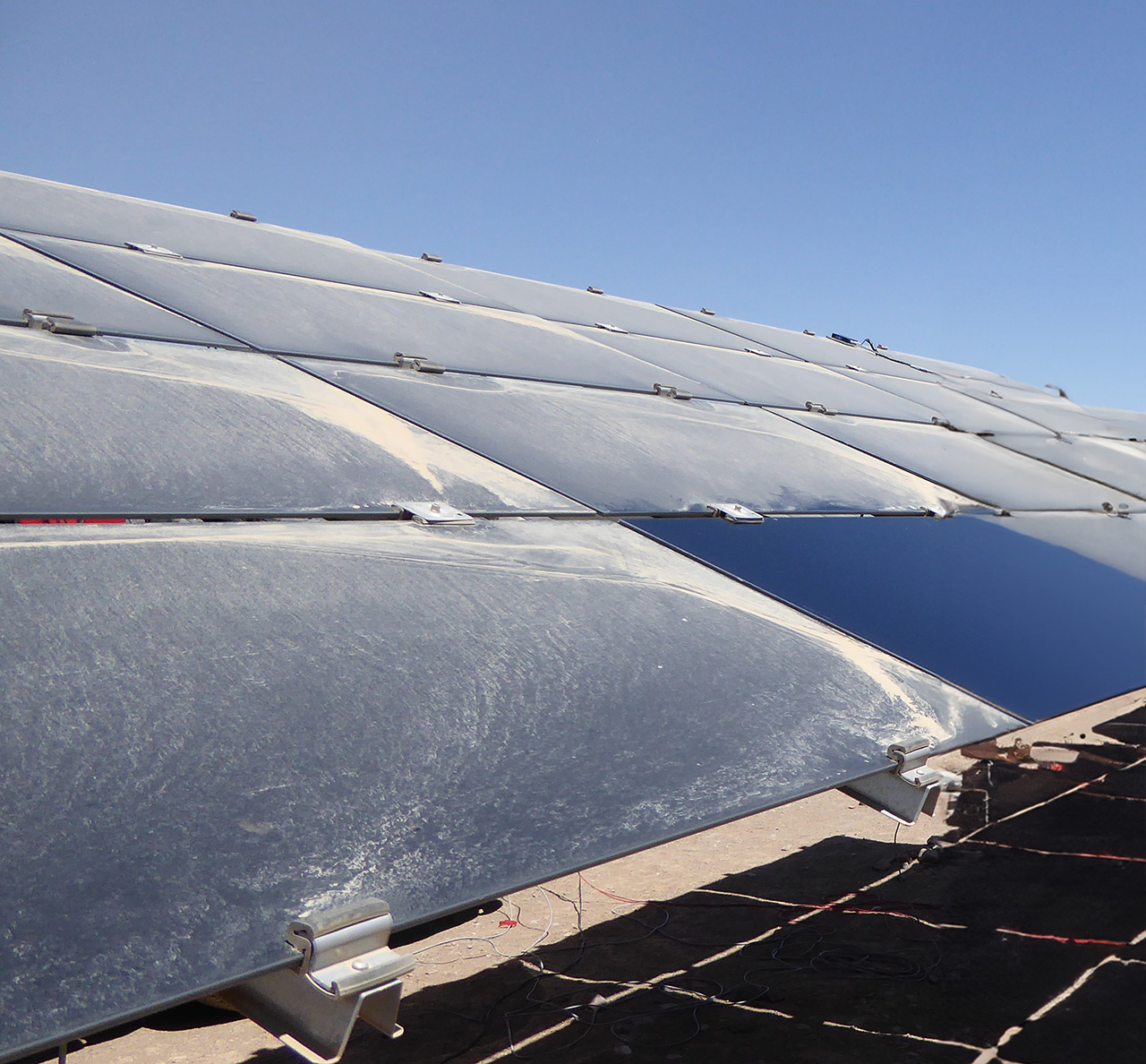

Fraunhofer ISE monitoring system is particularly suited for highly innovative PV projects and technologies: Floating PV, Agri-PV, infrastructure-PV, novel PV applications (i.e. new PV module technologies, innovative PV systems design, etc.)

Our services comprise:

- support in sensor selection

- KPI definition

- installation & operation

- data evaluation

- web-platform for data visualization (widget based, highly customizable)

- secure data transport and storage on Fraunhofer ISE servers

Enhanced Intelligent Monitoring

Automated fault detection offers a dependable solution for identifying failures and energy losses in PV systems. By continuously monitoring system performance and utilizing advanced algorithms, it can quickly detect anomalies and pinpoint the source of issues. This proactive approach allows for swift corrective action, reducing downtime and ensuring optimal system operation.

For this purpose, multiple methods have been created to:

- identify shading events using artificial intelligence

- determine of operating states (i.e. open circuit, inverter outage)

- compare current and historical Performance Ratio (PR)

- assess modeled vs. measured energy

- compare inverters performance (DC current, PR)

- determine energy losses due to soiling

- calculate Performance Loss Rate over long-term operation

These techniques have been thoroughly validated using a portfolio of more than a hundred commercial PV systems.

Development of artificial intelligence and deep-learning based algorithms

Within the PV O&M context, the development of AI and deep-learning based algorithms is a groundbreaking approach to enhance performance and efficiency. Fraunhofer ISE offers customized algorithm development as part of research projects tailored to clients' needs. These advanced algorithms analyze vast amounts of PV system data to identify patterns and trends, optimizing system performance and automating decision-making processes. By continually adapting and evolving, AI and deep-learning algorithms play a vital role in advancing solar energy operations and management.

Benchmarking Fault Detection Algorithms

Fraunhofer ISE can assess the client’s own algorithms by contrasting their results with those of other algorithms tackling the same problem