| Duration: | 05/2022 - 11/2025 |

| Contracting Authority/ Sponsors: |

Federal Ministry for Digital and Transport (BMDV) |

| Project Partners: | Fraunhofer ENAS, Fraunhofer ICT, Fraunhofer ILT, Fraunhofer IPT, Fraunhofer ISI |

| Project Focus: |

R2MEA – Series production of mobile fuel cells: Research platform for the roll-to-roll production of MEAs

The "R2MEA" project is focusing on innovative production processes for the manufacturing of the core component of fuel cells, the membrane electrode assembly (MEA). "R2MEA" is a sub-project of the joint project "H2GO - National Fuel Cell Production Action Plan" of 19 Fraunhofer Institutes to promote the ramp-up of fuel cell production for heavy-duty transportation in Germany.

In addition to battery electric vehicles, low-temperature fuel cells also represent an option for the heavy-duty and commercial vehicle sector to switch to emission-free mobility. The expected production volume for the electrochemical core component of the fuel cell, the MEA, is up to 240 million units p.a., which is not achievable with today's established manufacturing processes. In order to meet market expectations, existing plant concepts must therefore be adapted and scalable production methods developed.

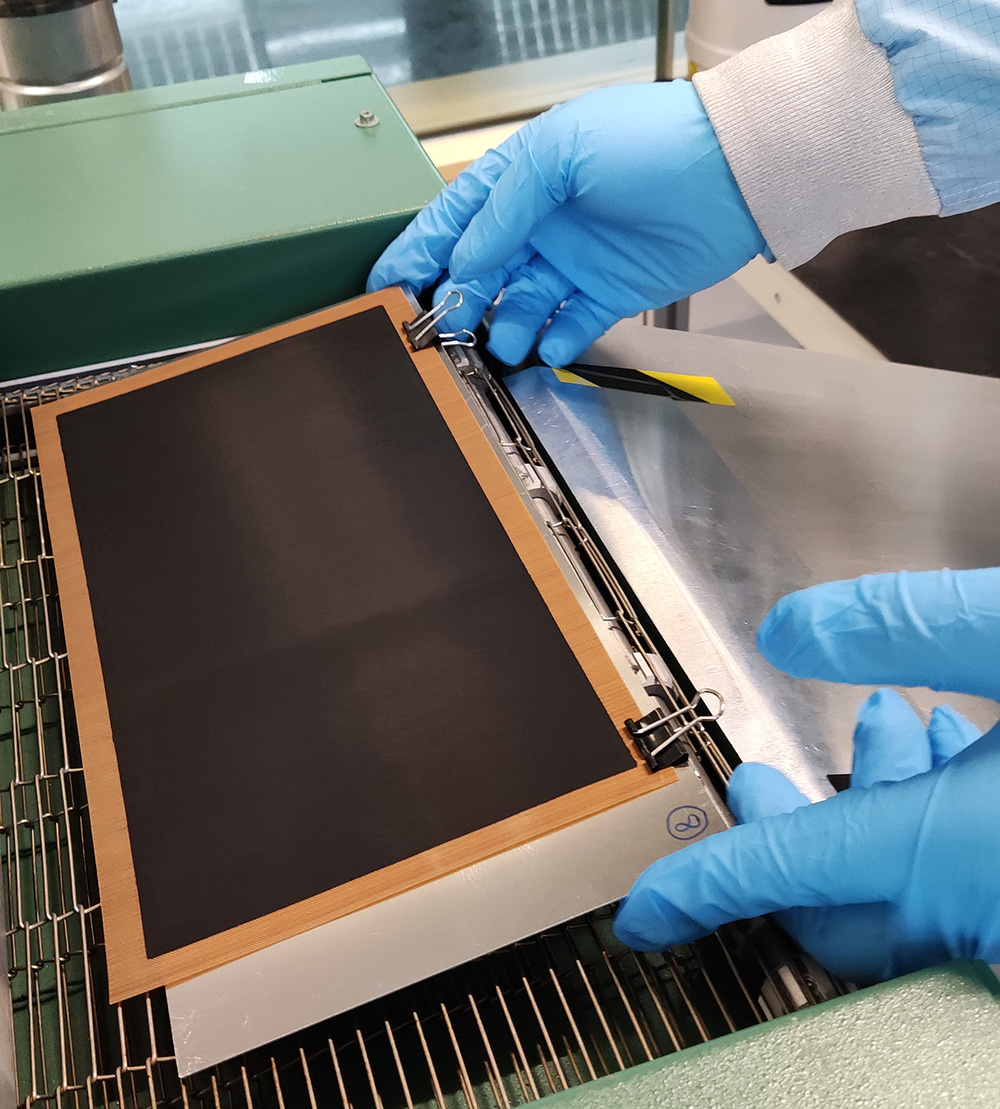

In order to support component manufacturers and machine and plant manufacturers in upscaling fuel cell production, the "R2MEA" research consortium, coordinated by Fraunhofer ISE, is investigating manufacturing processes and components. In "R2MEA", a research platform is being developed and established that is available to companies for production issues from catalyst production to the finished 7-layer MEA (i.e. the composite of membrane, catalyst layers, subgaskets and gas diffusion layers).

Questions that are addressed in R2MEA:

- How can the current production of catalyst powder be converted from batch processes to continuous processes?

- Are rotary printing processes also useful for applying catalyst layers in addition to the slot die that is primarily used today? Is direct printing on the membrane possible with the required high quality? Can laser drying processes shorten the drying time and dryer length?

- How can the membrane, catalyst layers, subgaskets and gas diffusion layers be cut to size in roll-to-roll processes? Which positioning and laminating processes are suitable for producing high-quality composites of the individual layers?

- How should transport containers be designed for intra- and external logistics?

In "R2MEA", innovative production processes and new system concepts are being developed that can represent membrane coating, separation, application of the subgaskets and cutting of the gas diffusion layer as a high throughput roll-to-roll process. In particular, the expected future requirements for structured MEAs are investigated by innovative production processes, thus preparing the production technology of tomorrow. To this end, the entire production chain is being researched on pilot systems in a technical center at Fraunhofer ISE.

Alongside the development of the research platform, Fraunhofer ISE is conducting extensive market studies on industry requirements, techno-economic analyses on the economic efficiency of various production processes and life cycle analyses on the ecological footprint. For example, the establishment of innovative coating processes, which enable direct coating of the membrane instead of the usual transfer process, helps to reduce costs due to the more efficient use of materials.

The joint project is aimed in particular at small and medium-sized companies along the entire value chain of fuel cell production - from manufacturing technology and mechanical and plant engineering to vehicle applications in heavy duty vehicles.

"R2MEA" is a sub-network of "H2GO - National Fuel Cell Production Action Plan". The entire H2GO network is being funded by the Federal Ministry for Digital and Transport Affairs with around 80 million euros as part of the National Innovation Program for Hydrogen and Fuel Cell Technology. The funding guideline is coordinated by NOW GmbH and implemented by Projektträger Jülich (PtJ).