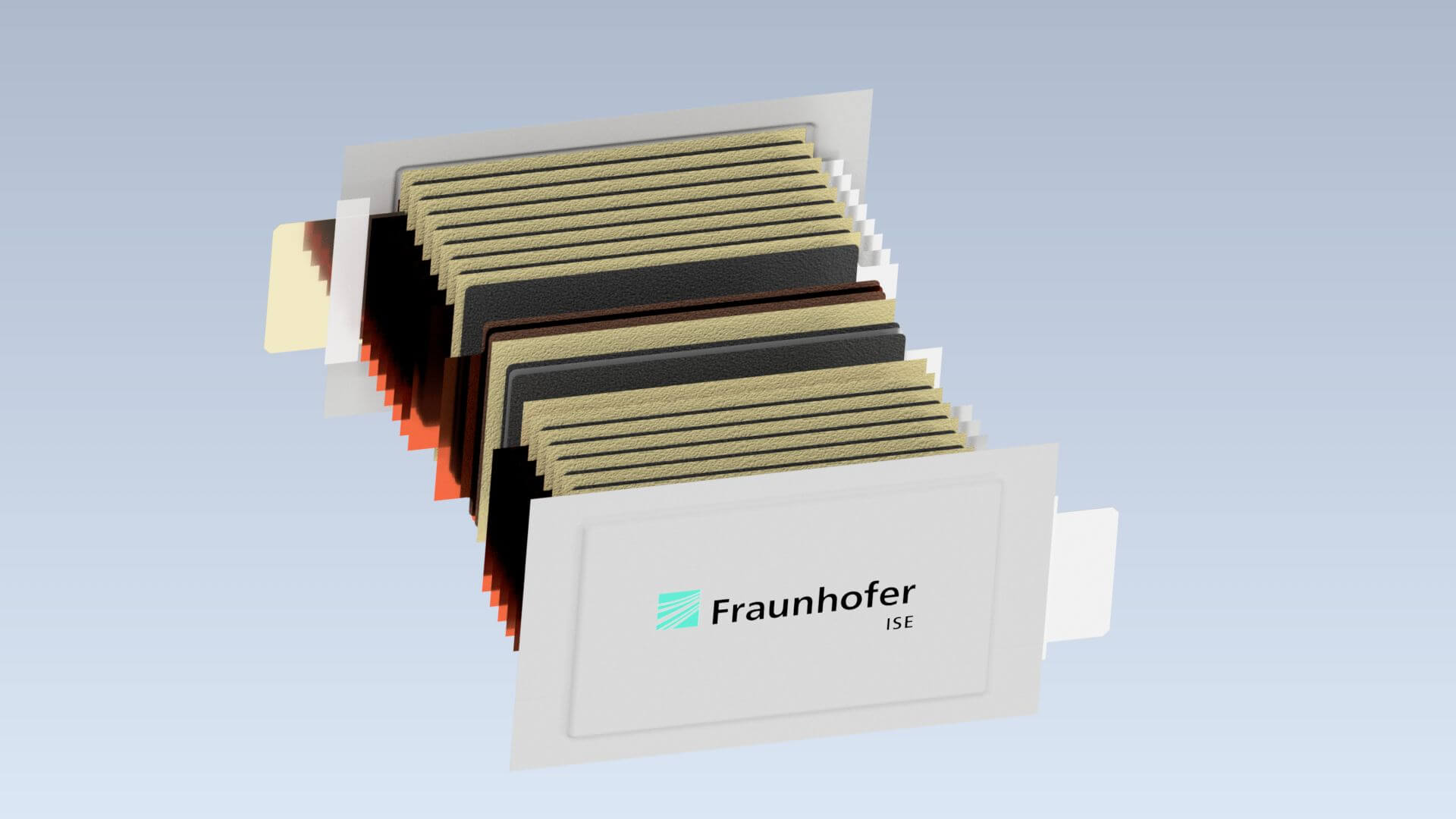

The All-Solid-State battery (ASSB) is considered a disruptive concept which increases the safety, performance and energy density compared to current lithium-ion battery cell technologies. By eliminating the need for liquid electrolyte, it also allows the implementation of completely new cell concept ideas and integration strategies.

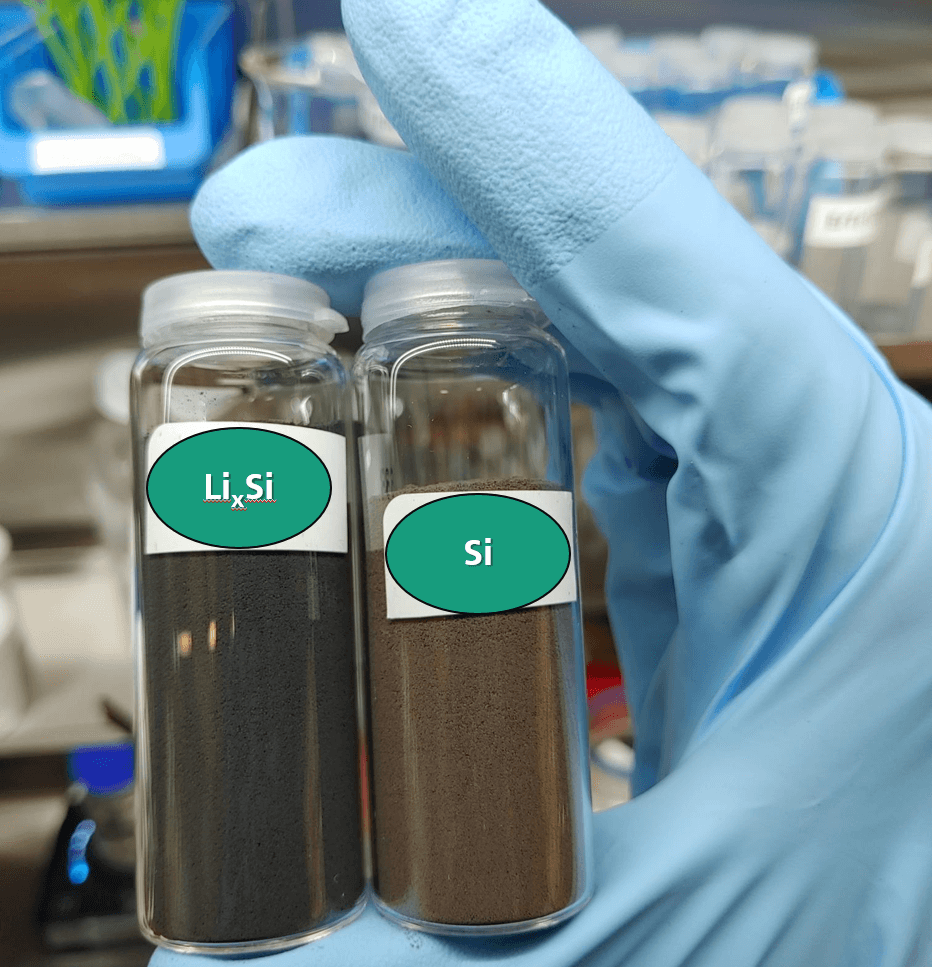

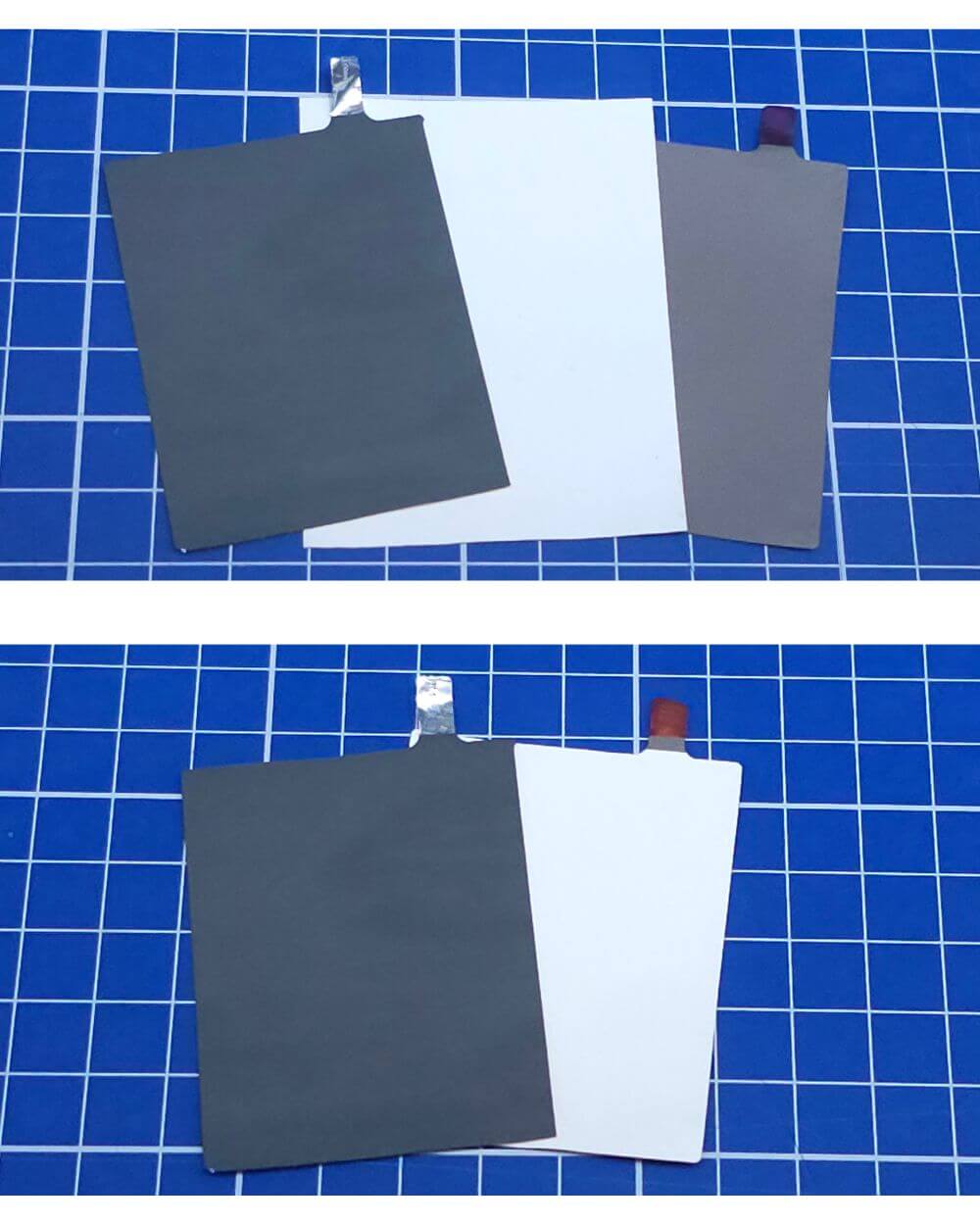

The research activities in the field of ASSB at Fraunhofer ISE range from the development of tailor-made electrode materials and manufacturing of battery cell components (separator and electrodes) to the assembly of the complete battery cell.

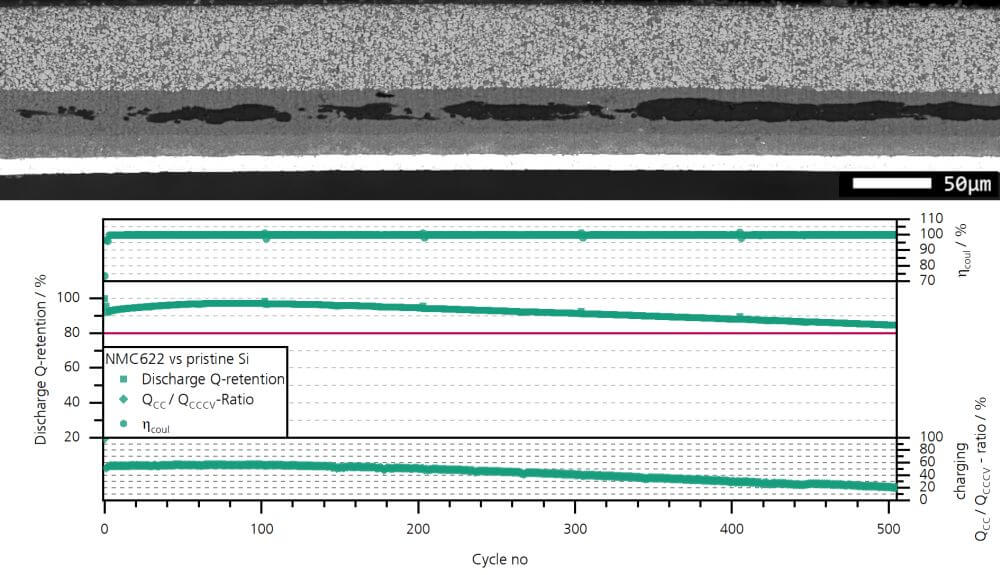

Based on our experience and techno-economic evaluations in the field of lithium-ion storage systems, we decided to focus mainly on the use of sulfide electrolytes in ASSB. This class of materials allows high lithium-ion conductivities at room temperature (10-3-10-2 S∙cm-1) without the need for an additional liquid electrolyte. Similar to polymer solid electrolytes, sulfide electrolytes also combine the material properties required for industrial processing with a low crystalline density, allowing high energy densities (> 400 Wh∙kg-1 / > 1000 Wh∙l-1) to be achieved by using conventional cathode materials (e.g. NMC-based materials such as LiNi0.8Mn0.1Co0.1O2).