Our Wet and Dry Chemical Processes are all aimed at creating perfectly structured and conditioned surfaces for the production of solar cells. Structuring is carried out using etching processes, while conditioning involves cleaning processes.

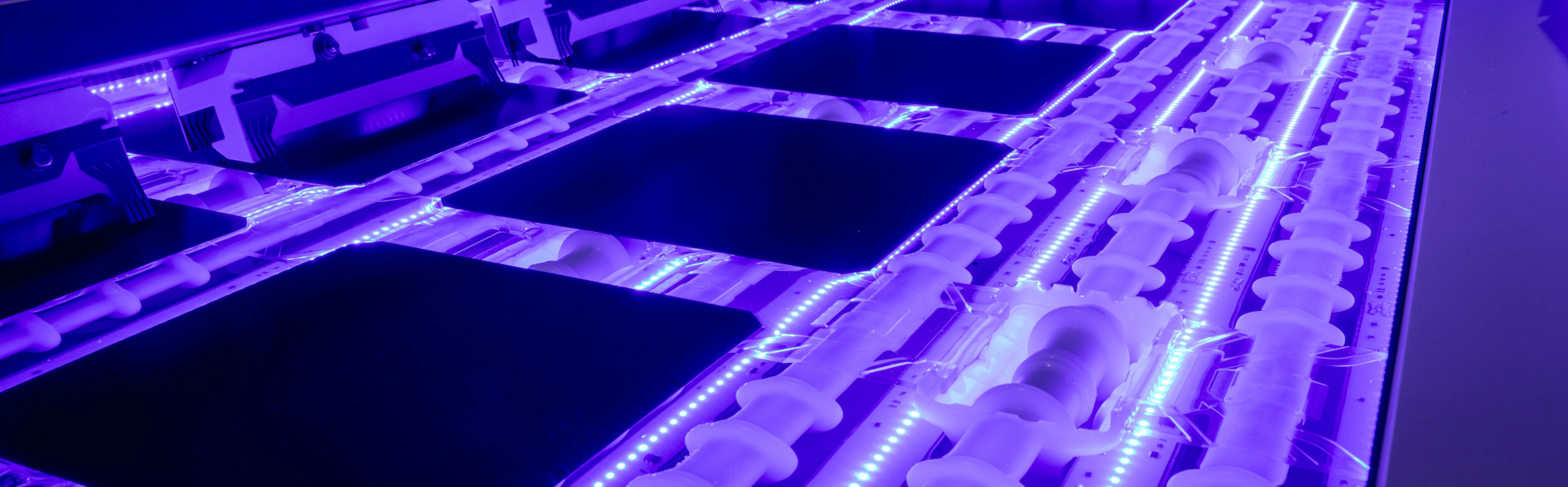

Etching processes can be carried out dry-chemically by reaction with elemental fluorine, and there are also wet-chemical etching processes which are usually carried out in a hot process solution. One such structuring process is the alkaline texturing process, in which the surface of silicon wafers is provided with a micro-pyramidal structure, which improves the optical properties of the cell. For these batch processes, we are researching approaches with novel chemical formulations and improvements in rinsing processes to increase resource efficiency. Short, one-sided etching processes are carried out inline, where the wafers are transported horizontally but only come into contact with the etching medium on the underside. Our work is aimed at improving the one-sidedness of the processes and increasing the throughput of the systems by improving the system technology. Metallic conductor tracks can also be produced in wet-chemical (galvanic) processes. Our work is aimed at depositing contacts of the highest quality with low process complexity. At the same time, we replace costly and scarce silver with copper.

The work is flanked by CFD simulations with which we can depict and improve flows and reactions in systems. A new field of work is the wet-chemical deposition of coatings. The current focus here is on the spray (pyrolytic) deposition of anti-reflective coatings and perovskite coatings.