Contact Press / Media

Dr. Wolfgang Kramer

Waste heat utilization

Fraunhofer ISE

Heidenhofstr. 2

79110 Freiburg

Phone +49 761 4588-5096

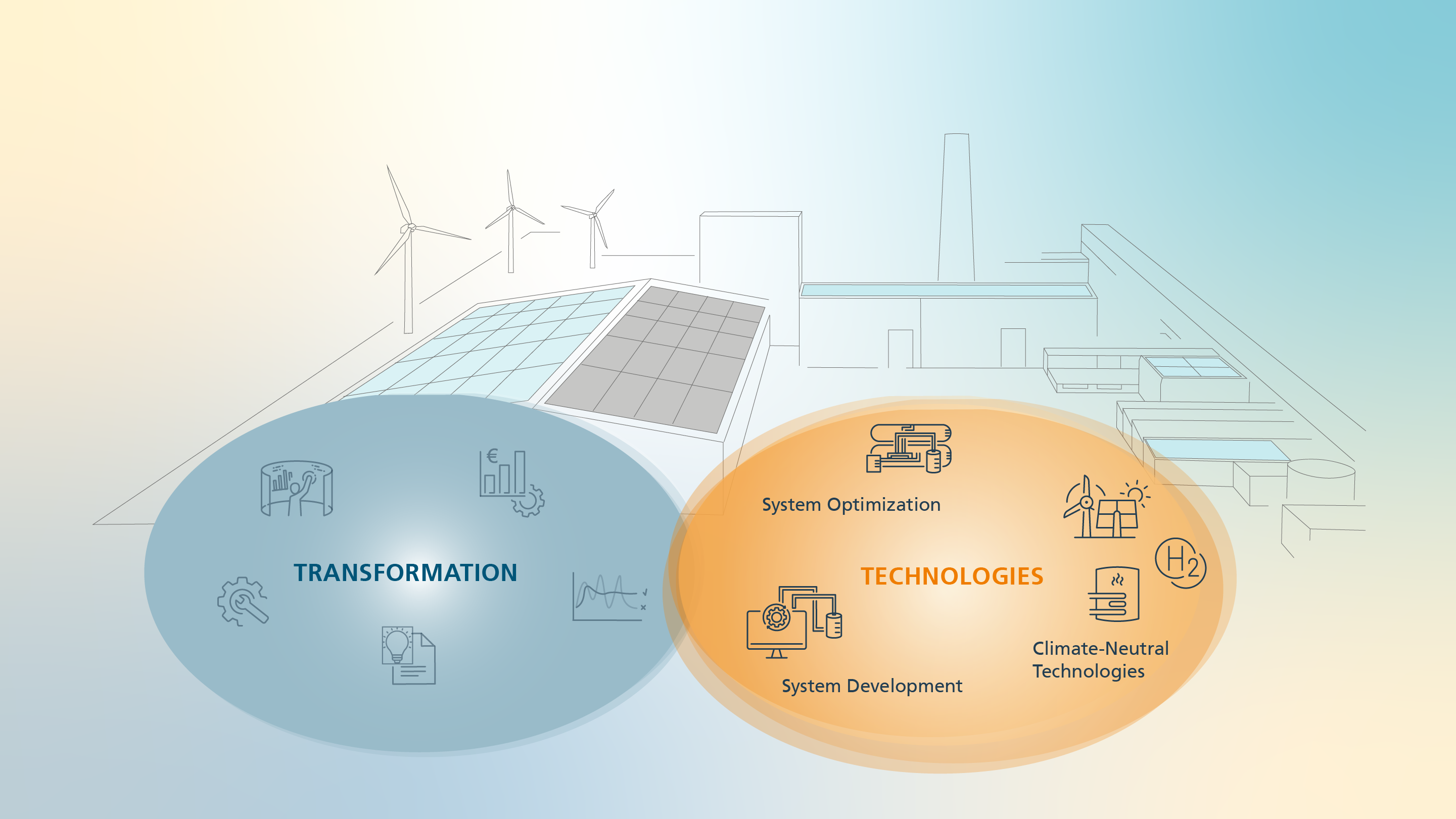

Fraunhofer ISE is working on key technologies that pave the way to a climate-neutral industry. This includes the development and testing of climate-neutral technologies as well as system development and plant optimization.

Various technologies can be used to decarbonize production processes and plants. The selection of suitable technologies depends on the respective requirements of the application as well as the available resources and infrastructure. Optimum design and integration of these technologies is the prerequisite for high efficiency and cost-effectiveness.

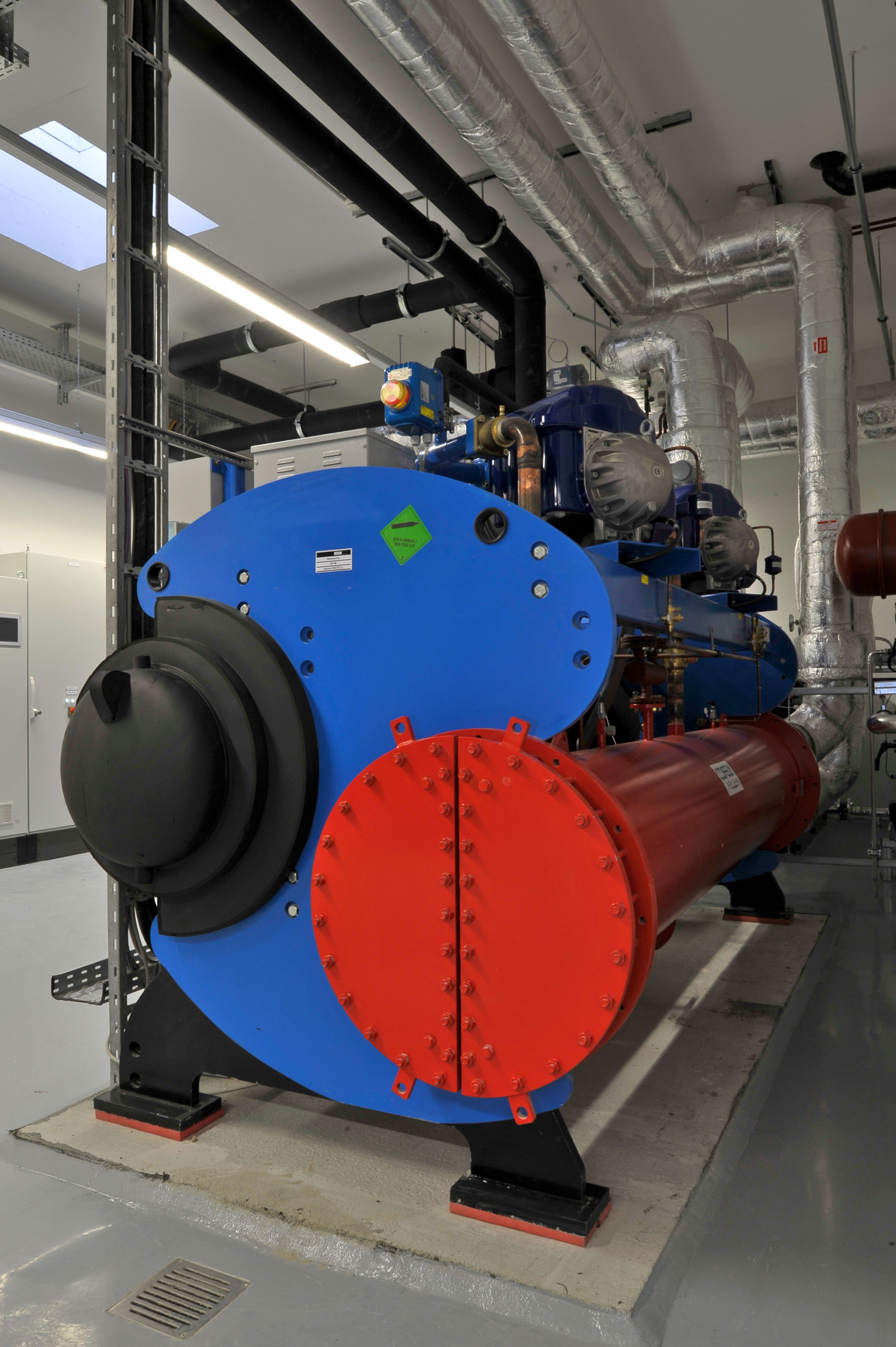

Heat pumps upgrade environmental or waste heat by raising the temperature and thus making the energy usable again. The useful heat is a multiple of the electrical energy used, which in turn is ideally generated from renewable sources. In industry, heat pumps are used in power ranges up to the MW range and for temperatures up to around 250°C and can be adapted to the requirements of the industry or process. Heat pumps are particularly economical when both heating and cooling are required in process chains. In combination with heat storage systems, they can also provide flexibility options for electricity procurement.

For temperatures above 250°C or in applications without sufficient waste heat sources, electrical energy (e.g. generated from renewable sources) can be converted directly into heat using various technologies. Examples include heating rods or immersion heaters for heating a transfer medium or process medium, or electrode boilers for generating process steam. In combination with heat storage systems, direct electric heating systems can provide additional flexibility options when purchasing electricity or help to reduce peak loads.

In thermal collectors, solar radiation is converted directly into heat and transferred to processes or heat storage units. The thermal storage enables the decoupling of generation and use of renewable heat over time. With various collector technologies, process heat from low temperatures up to around 200°C can be provided economically. Usually, solar thermal energy supplements another heat source that ensures security of supply. By investing in solar thermal energy, you make yourself independent of fluctuating energy prices; as an alternative to your own investment, many providers of solar thermal technologies now offer heat supply contracts.

Photovoltaics converts solar radiation directly into renewable electrical energy. With a dedicated roof-, façade- or ground-mounted system, electricity procurement can be reduced and renewable process heating or cooling can also be generated with heat pumps or direct electrical heating systems. Depending on the application, the use of thermal or battery storage systems can significantly increase the renewable share of the energy consumed.

Heat or cold storage systems enable the temporal decoupling of the generation and use of renewably generated heat or cold, both for renewable heat (solar thermal, geothermal) or via electricity. In times of low purchase prices, heat (power-to-heat) or cooling can be generated cheaply with electrical energy and is later available for your processes as required. Waste heat can also be stored so that it can then be used again as required.

Electrical storage systems (large battery systems) are useful where large quantities of renewable electricity cannot be used or fed to the grid directly, or where peak loads need to be reduced (peak shaving).

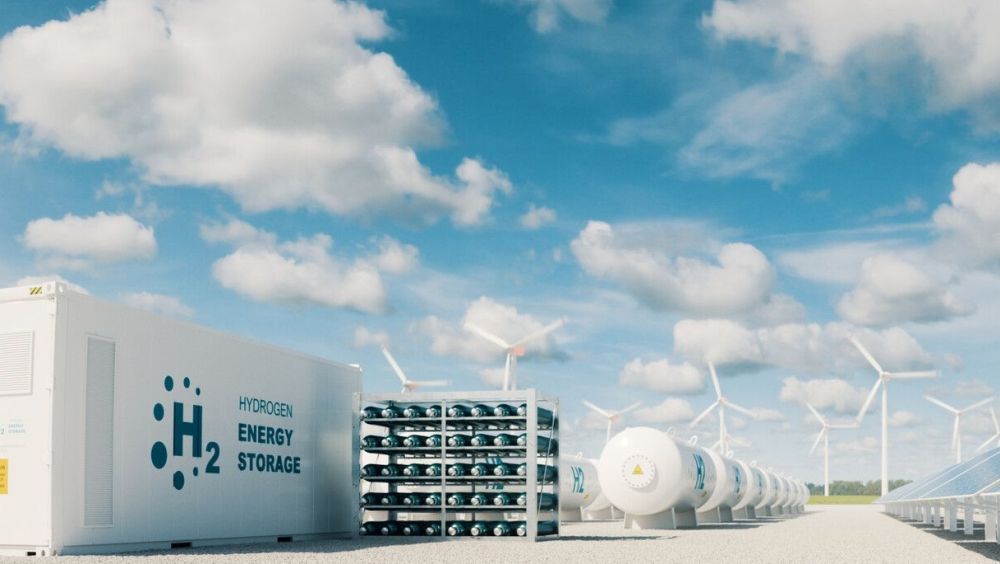

Hydrogen can be used both as a chemical feedstock and as an energy carrier. If it is produced from renewable electricity using electrolysis, for example, it can be used as a renewable energy source and also as a feedstock for synthetic fuels. Plants for the production of hydrogen or "green" synthetic fuels make sense and can decarbonize processes, where hydrogen or fuels cannot be replaced by other renewable sources.

Technologies that capture CO2 and thus permanently remove it from the atmosphere or carbon cycles are summarized under the term "negative emission technologies". Through offsetting and counterbalancing hard-to-abate emissions, they enable complete climate neutrality even if there are otherwise unavoidable residual emissions.

In addition to process heat supply, the provision of industrial cold is an area with high energy requirements. The use of electrically driven compression refrigeration enables decarbonization through the use of renewable electricity. If suitable (waste) heat sources are available, thermally driven cooling processes can also be an attractive solution. If there is also a heating requirement in your process chains, a heat pump may be able to profitably cover both the heating and cooling requirements.

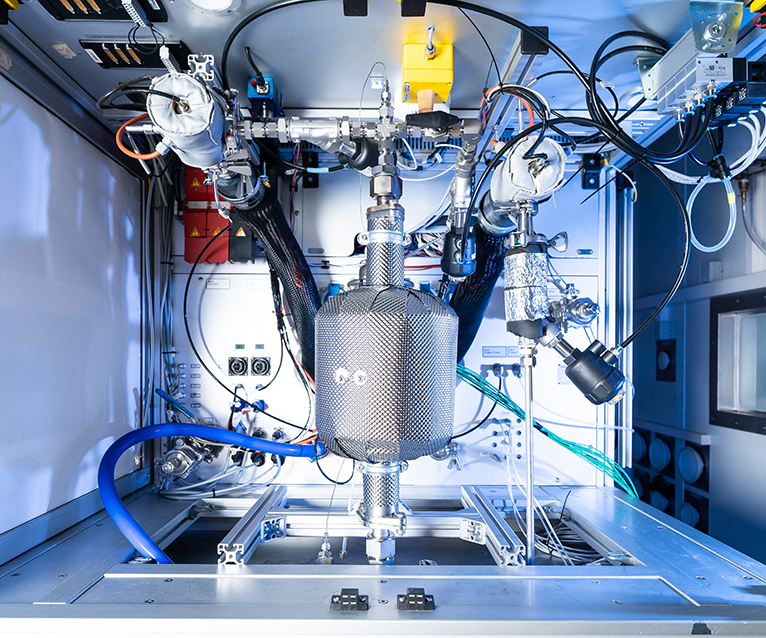

Energy-efficient and resource-conserving production facilities are the key to a climate-neutral industry. To this end, we develop systems for industrial applications and optimize existing plants. We rely on innovative technologies to maximize the use of renewable energies and reduce emissions.

The provision of process heat at various temperature levels represents the largest energy requirement in industry. In order to make it climate-neutral, combinations of different technologies are often used. In hybrid supply systems, the use of heat and cold storage systems facilitates sector coupling and decarbonization, but also poses challenges for the control and operation of the systems. In the case of existing steam networks, it is important to clarify whether the steam should be supplied from renewable sources or whether a switch to alternative heat supplies ("de-steaming") is possible and economically viable.

Waste heat can be harnessed with the help of heat storage systems. Heat pumps or other heating technologies "upgrade" waste heat and make it usable again at higher temperatures. Which technical solution makes sense depends heavily on the temperature levels of the waste heat and heat requirements. Electricity can also be generated from high temperature waste heatusing ORC (Organic Rankine Cycle) systems.

Wastewater is often not only a source of waste heat, but can also contain valuable residual materials such as metals, minerals or acids, which can be recovered and reused with membrane-based systems. Treating wastewater until it is completely dry ("zero liquid discharge") can be useful in some cases.

In industry, there is usually a complex network of different electrical and thermal energy requirements. In order to achieve climate neutrality, it is important to cover as much of this demand as possible from renewable sources. Solar thermal energy and photovoltaics are obvious options, but waste heat, geothermal energy and wind power can also make useful contributions. The correct integration of these renewable sources, e.g. by means of storage technologies, is crucial to whether a solution can be economically viable.

We not only support you in developing technical solutions, but also evaluate and optimize them economically. Security of supply and the reduction of dependencies are further constraints that need to be considered. In an optimization, we take into account the specific goals, constraints, needs and requirements of your process and your company as a whole.