Individualized productions, such as in the Photovoltaic Technology Evaluation Center (PV-TEC), place high demands on the flexibility of software systems for production monitoring and the collection, interlinking and analysis of the resulting data due to the wide variety of manufactured products and the constantly changing production capabilities and processes. Conventional production control systems only meet these requirements to a limited extent, partly because the database structures are optimized for highly standardized data flows, which makes the processing of partly structured and unstructured data from heterogeneous data sources more difficult and thus the implementation of Industry 4.0 and big data concepts.

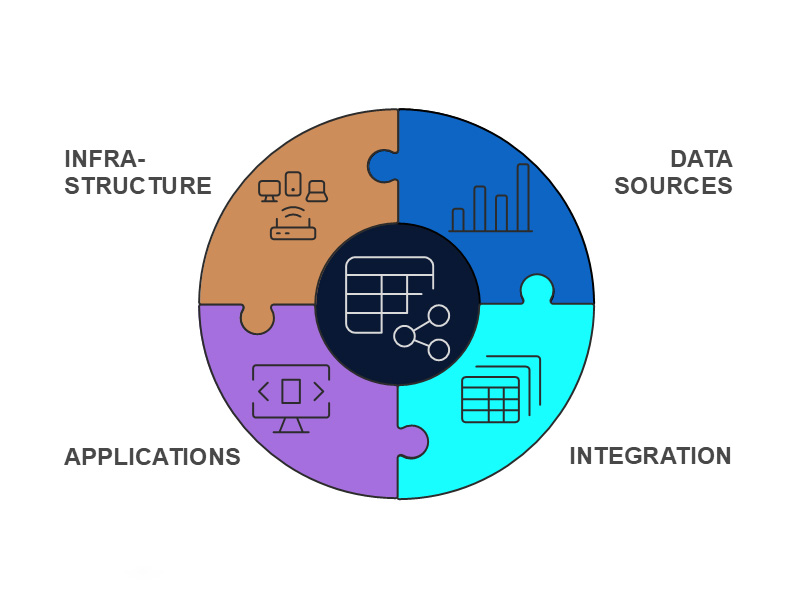

We are therefore developing innovative modular digitalization concepts for planning and tracking production orders as well as collecting and analysing the resulting data, which meet the requirements of individualized productions through two disruptive approaches:

- the dynamic recording of all production data without structural specifications (data lake) and

- the use of a network of NoSQL databases for the separate storage of raw data and metadata with an integrated metadata layer for interlinking and pre-structuring the data (lakehouse) for queries and analyses.

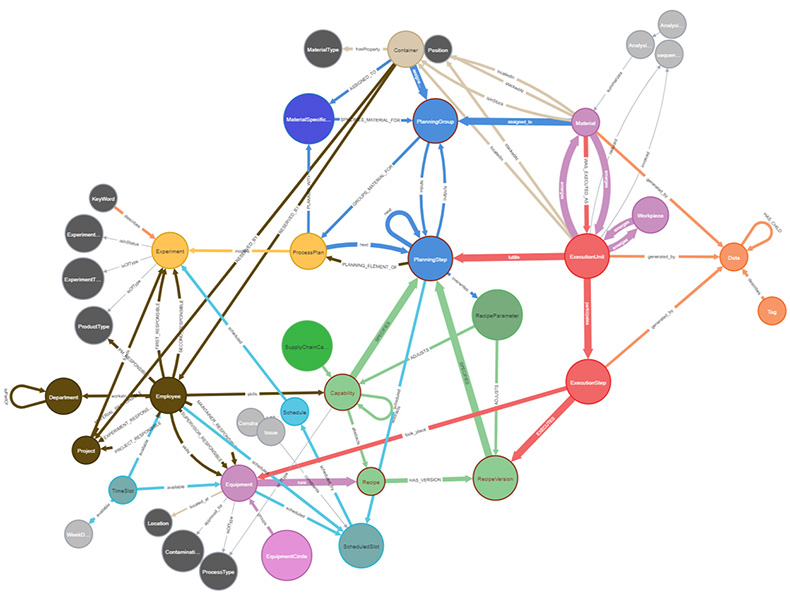

Typically, we use graph databases to store metadata (context information), document databases to store production data and other databases and storage solutions specialized for specific data types, which are linked via reference IDs to form a database network.