The performance of electrical energy storage devices is decisively influenced by the nature of the electrodes. According to the current state of the art, they are manufactured using a wet coating process. In this process, flowable masses consisting of active material, conductivity additives and the binder, dispersed in a solvent, are applied to electrically conductive carrier materials. The process chain – from the starting materials to the ready-to-use electrode – includes the process steps of mixing and dispersing, the wet application itself, the subsequent drying and, if necessary, calendering (densification). Each individual step must be adapted to the materials used and optimized with regard to the targets and requirements for the electrode.

New materials and battery technologies often require the development of new manufacturing processes and techniques. To this end, we conduct research and development in the following areas:

- Mixing and coating technology, including scalability

- We offer recipe development and paste formulation for coating processes with doctor blade and slot die. The entire process can be carried out in both sheet-to-sheet and roll-to-roll processes under normal laboratory conditions (45% relative humidity) and under dry room conditions (relative humidity <2%).

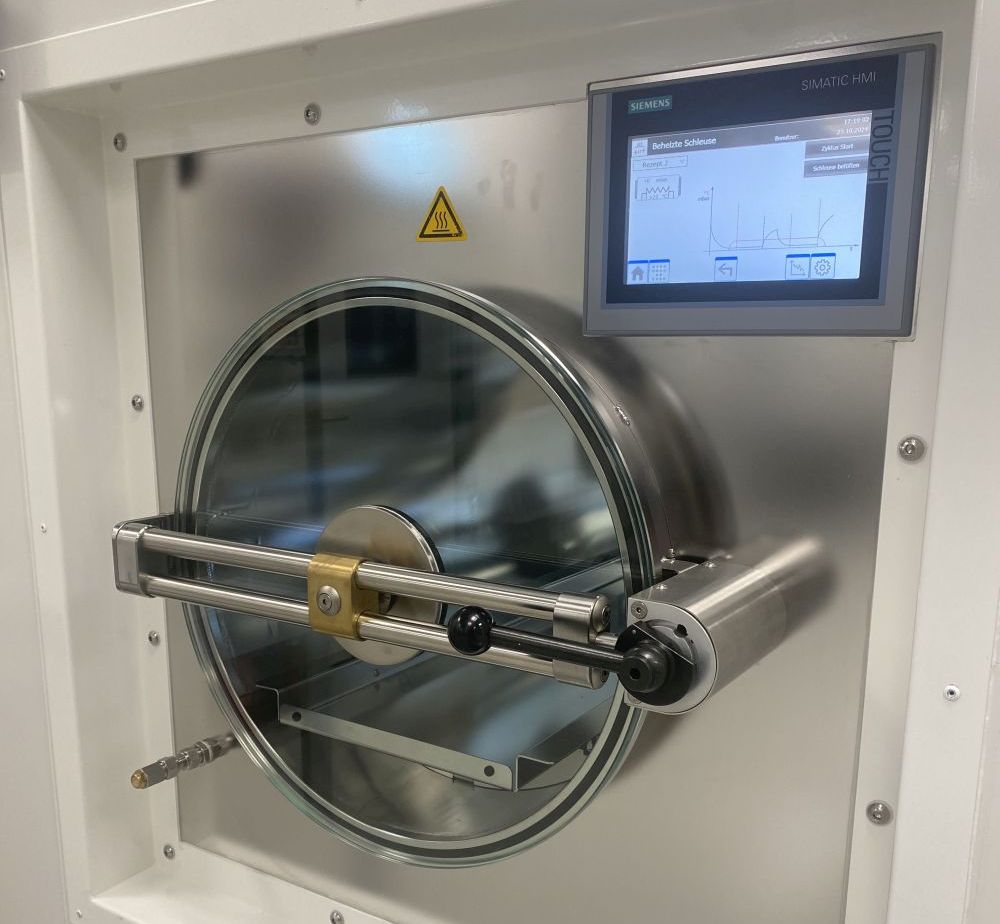

- We produce electrodes for solid-state batteries with a sulfide-based electrolyte under an inert atmosphere

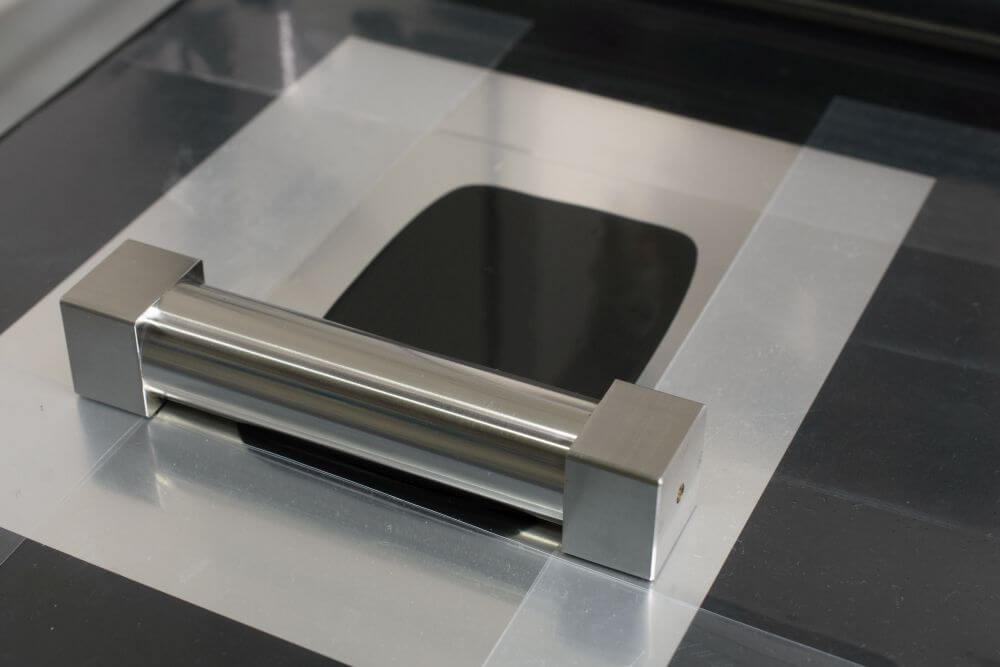

- We also offer energy-efficient dry coating processes in a single-stage direct calendering process and a discontinuous hot pressing process

- The Technical Center Vacuum Coating offers the possibility to carry out processes for thin-film batteries and corrosion protection layers.