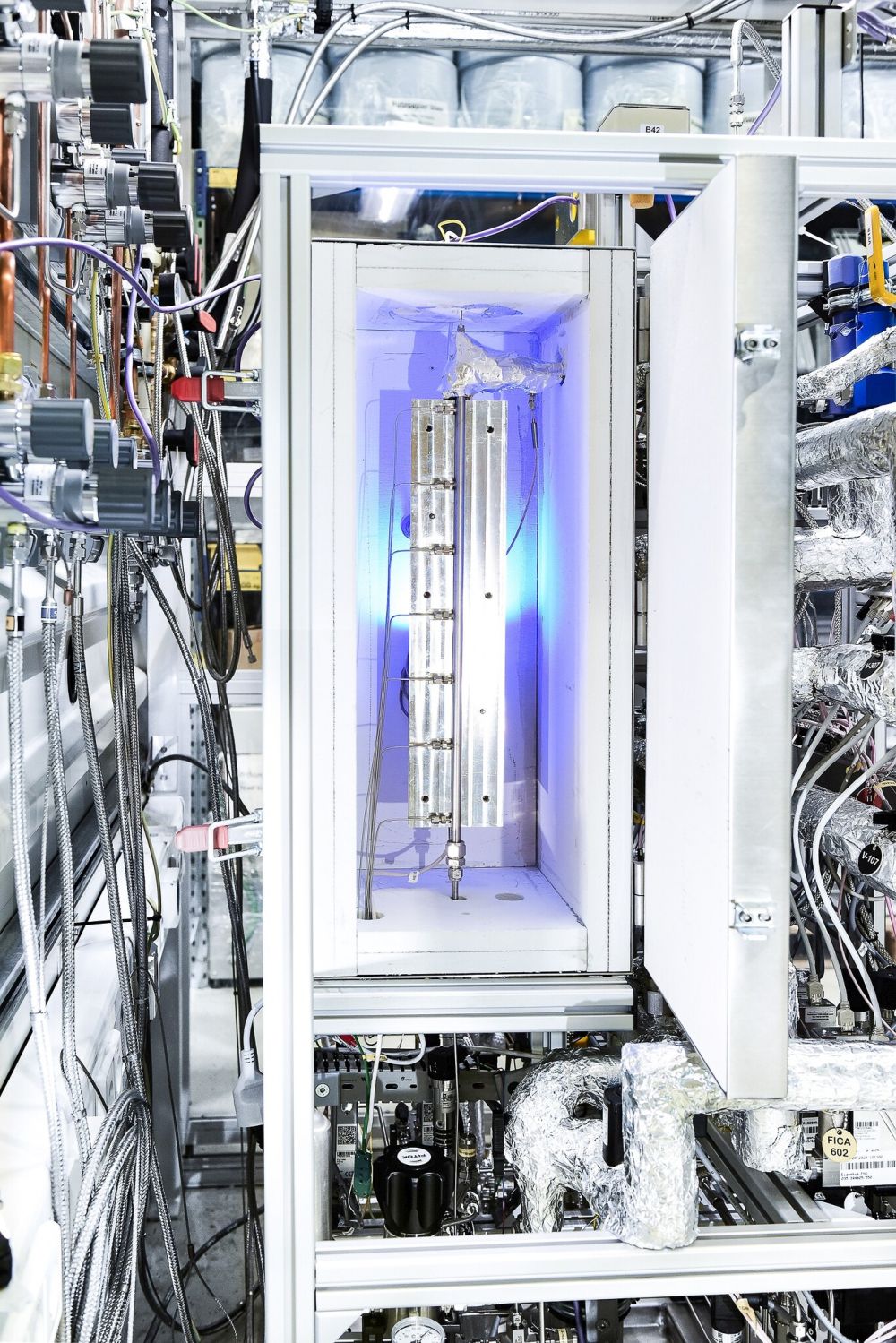

We develop, optimize and evaluate chemical processes for the production of sustainable energy carriers and chemicals, ideally based on green hydrogen and CO2/N2. These include, in particular, power-to-X (PtX) processes for the production of ammonia, sustainable aviation fuels and methanol, as well as the derivatives dimethyl ether (DME) and oxymethylene ether (OME). We are investigating the new requirements for chemical processes resulting from the shift from fossil to sustainable feedstocks, such as dynamic operation based on fluctuating renewable energy generation. On the one hand, we are researching catalytic processes as part of catalyst screenings and kinetic studies. On the other hand, we are investigating product processing, e.g. through distillation, absorption and adsorption. By means of process intensification, e.g. the coupling of reaction and separation processes, we are developing new, compact and efficient manufacturing processes.

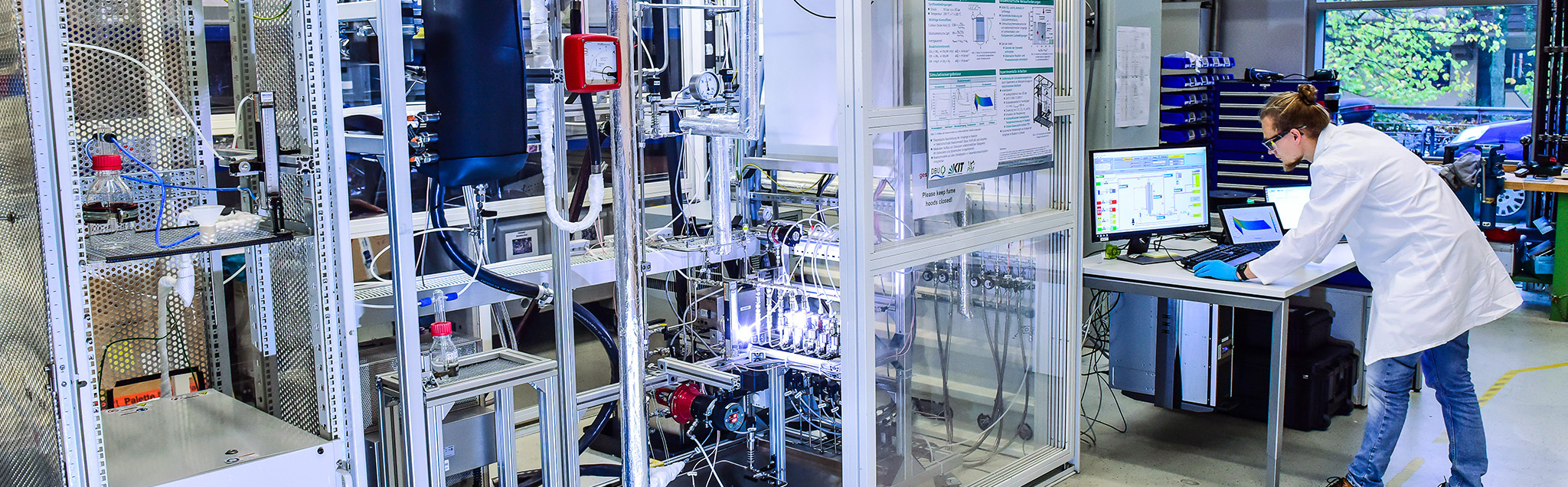

Experimentation and modeling go hand in hand for us: based on our facilities from laboratory to pilot plant scale, we create validated simulation tools that enable successful scale-up of the processes to industrial production scale.