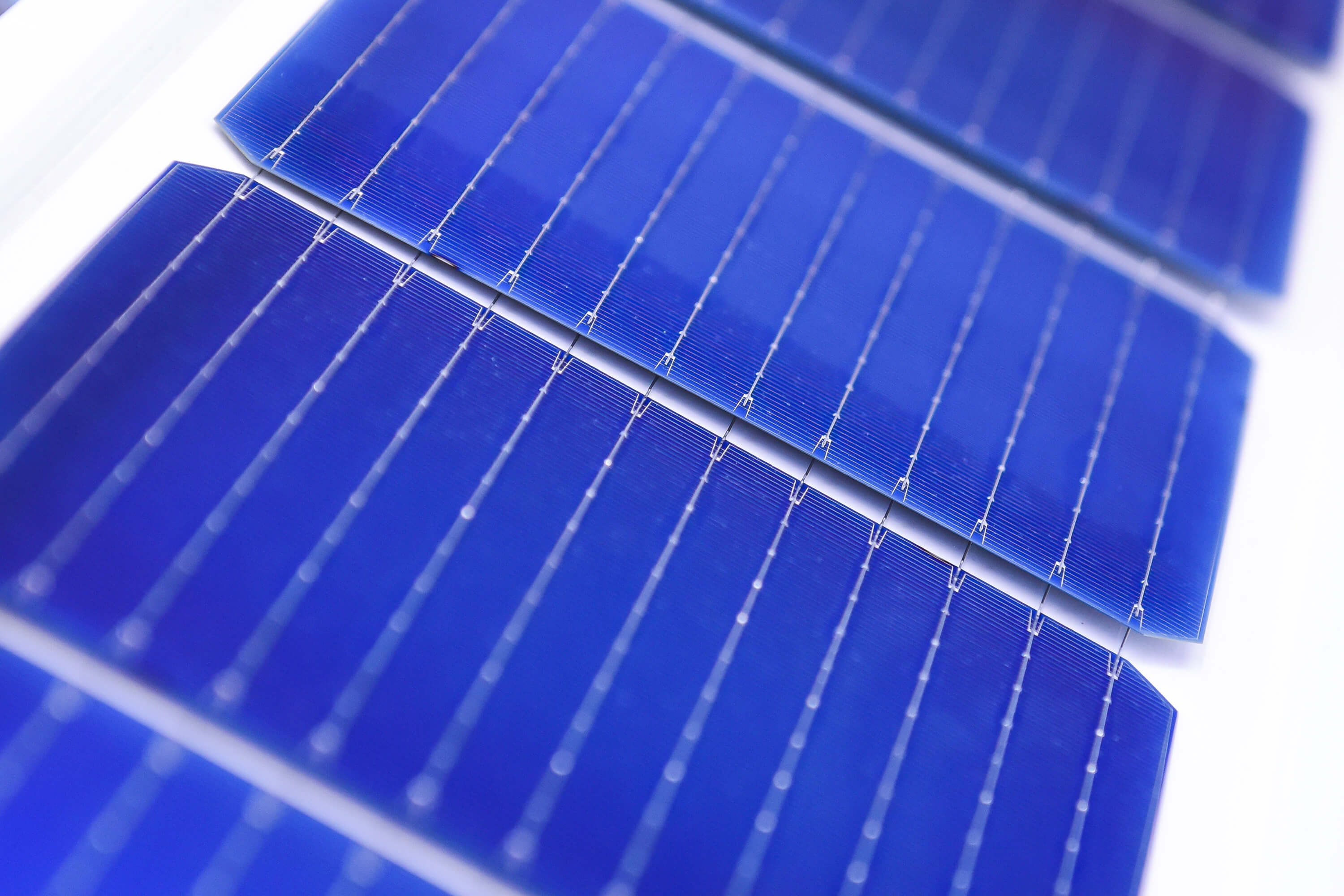

The development and continuous optimization of new solar cell technologies and solar cell formats (TOPCon, SHJ, Tandem) is leading to an increasing number of busbar structures on solar cells and the use of shingle technology. In addition, new high-efficiency technologies require joining methods with low process temperatures. Examples of this are conductive bonding or soft soldering with solder alloys with a lower melting point than the tin-lead solder mainly used in photovoltaics. The use of round wires in comparison to conventional cell connectors makes it possible to reduce electrical and optical losses. By increasing the number of round wires per cell, a lower series resistance is achieved and the optimized light scattering of the round wire back onto the solar cell allows a higher module output to be achieved.

The round wires consist of a copper core with a diameter of 200 µm to 400 µm and are coated with a lead-free or lead-containing solder. As with the interconnection of solar cells with conventional cell connectors with a rectangular cross-section, the round wires are fixed to the solar cells using soft soldering or conductive adhesive to connect the cells. One challenge in interconnection technology for solar cells is the occurrence of thermomechanical stresses, which can lead to microcracks in solar cells and limit the service life of PV modules.

At Fraunhofer ISE, we are working on the development of corrugated wires that reduce the thermomechanical stresses and enable a busbar-free interconnection of the contact fingers or the low-stress interconnection of back-contact solar cells. Furthermore, an optimized area utilization in the PV module is being analyzed by reducing the cell spacing up to the cell overlap. The focus here is on the requirements of the round wire in the transition area of the cells and the mechanical loads that act on the cell edges.

We are also working on shingle technology, electrically conductive bonding of high-efficiency solar cells and lead-free soldering for RoHS-compliant solar cell interconnection.