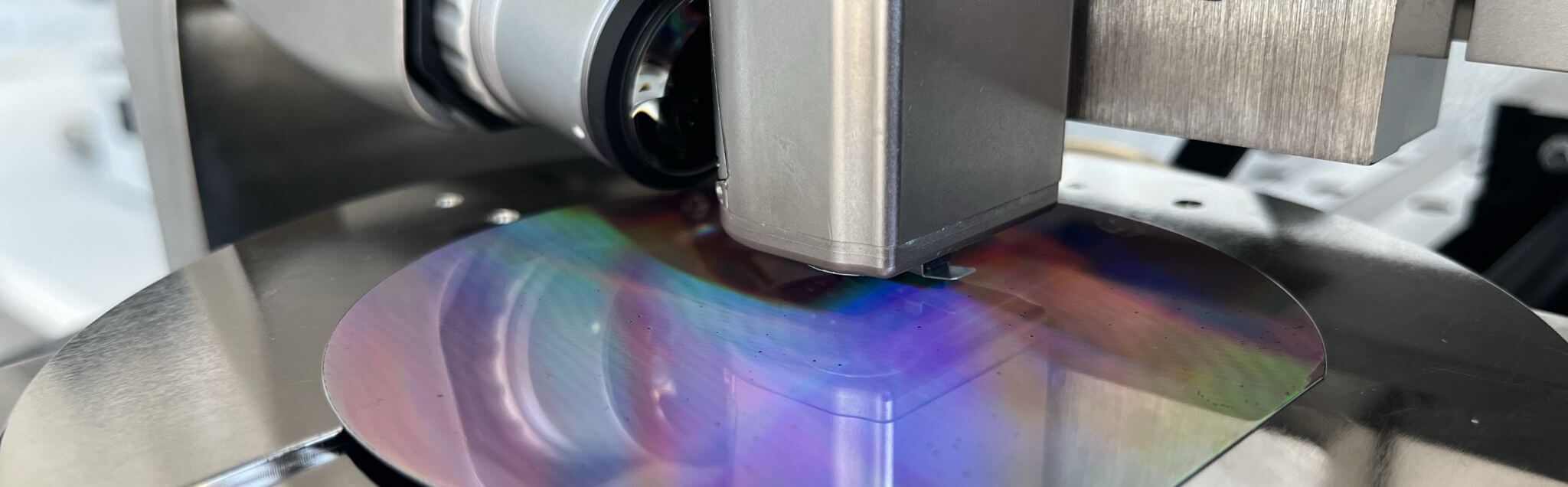

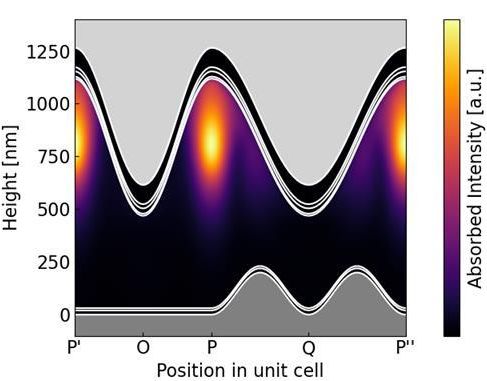

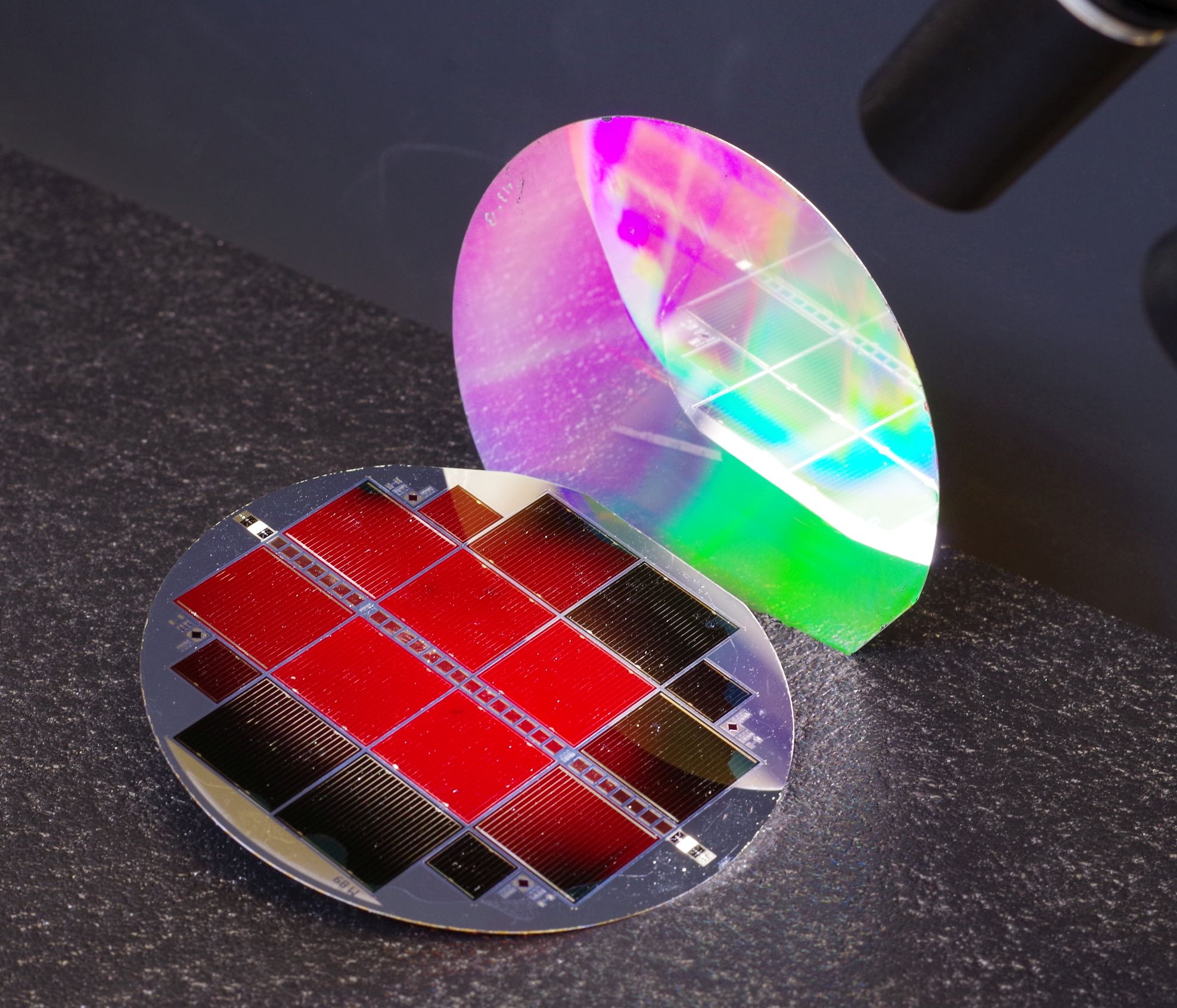

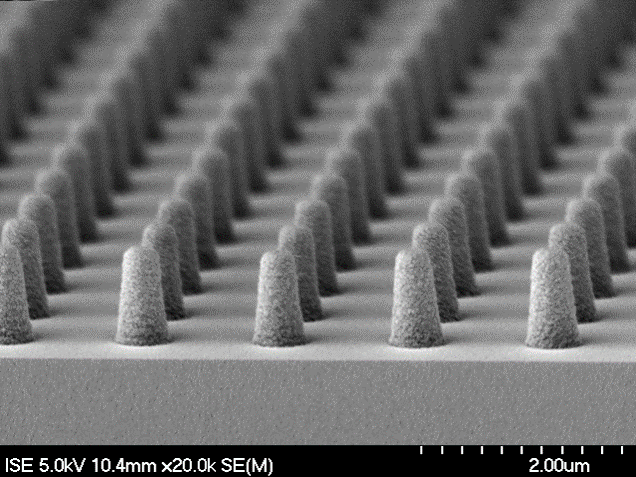

We develop solutions based on micro- and nanostructures for solar cells and other photovoltaic components such as photovoltaic cells for transmitting power using laser light, but also for related components such as LEDs. The technical focus is on a combination of nanoimprint lithography with different structures, photolithography, physical vapor deposition processes and wet and dry chemical etching processes.

Our range of services includes feasibility studies, small series production and product development up to finished industrial prototypes. We cover the entire spectrum from photonic design and process development to the characterization of prototypes and small series.

As we are experts in both nanostructuring and the realization of highly efficient solar cells, we can use nanostructures profitably in solar cells without impairing them electrically. We can map the entire process chain from the wafer to the photonic component.