The membrane electrode assembly (MEA) is the electrochemical heart of fuel cells and electrolysers, where water is split into oxygen and hydrogen in electrolyzers using current and voltage, and where hydrogen is converted into electricity, heat and product water in fuel cells. The ramp-up of the fuel cell and electrolyser economy requires a comprehensive understanding of the optimal, efficient and sustainable production of MEAs.

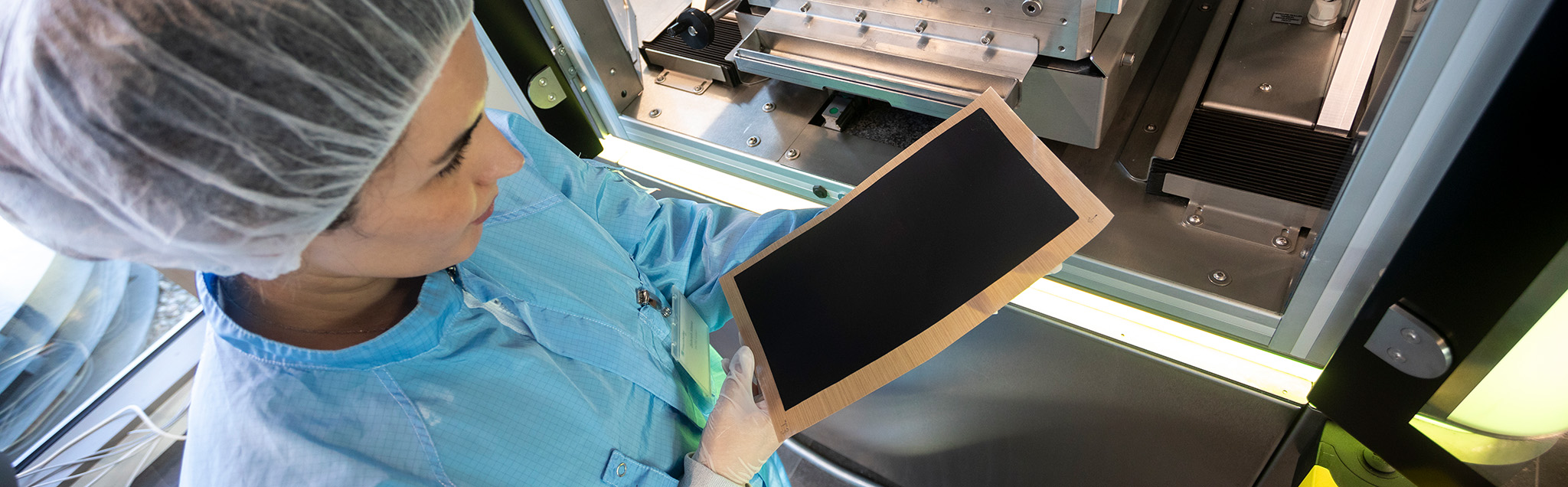

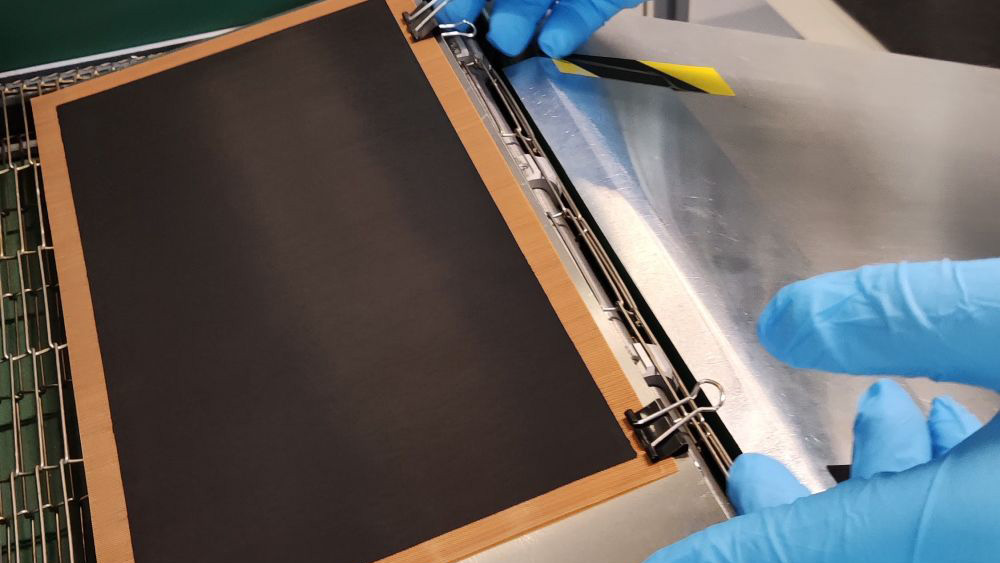

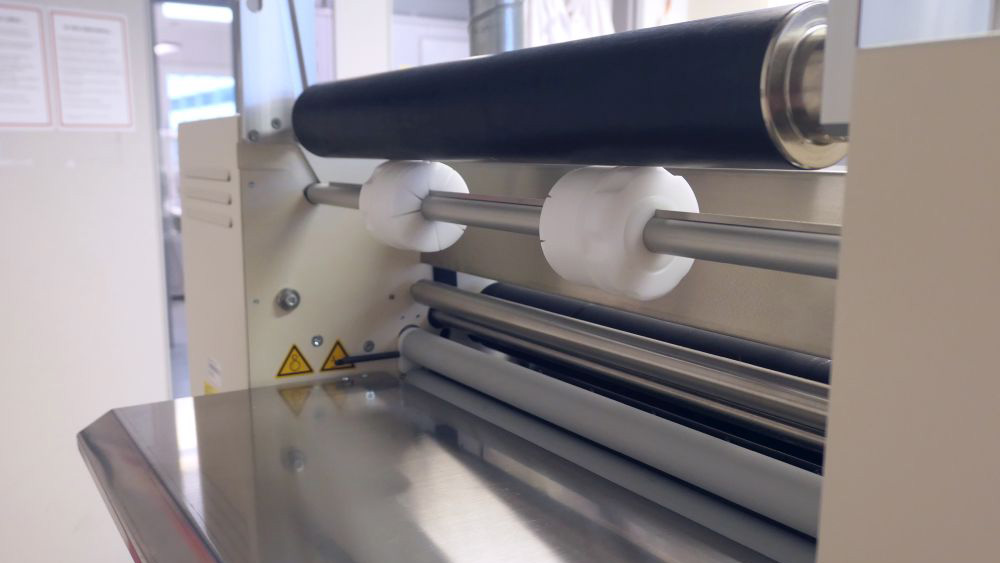

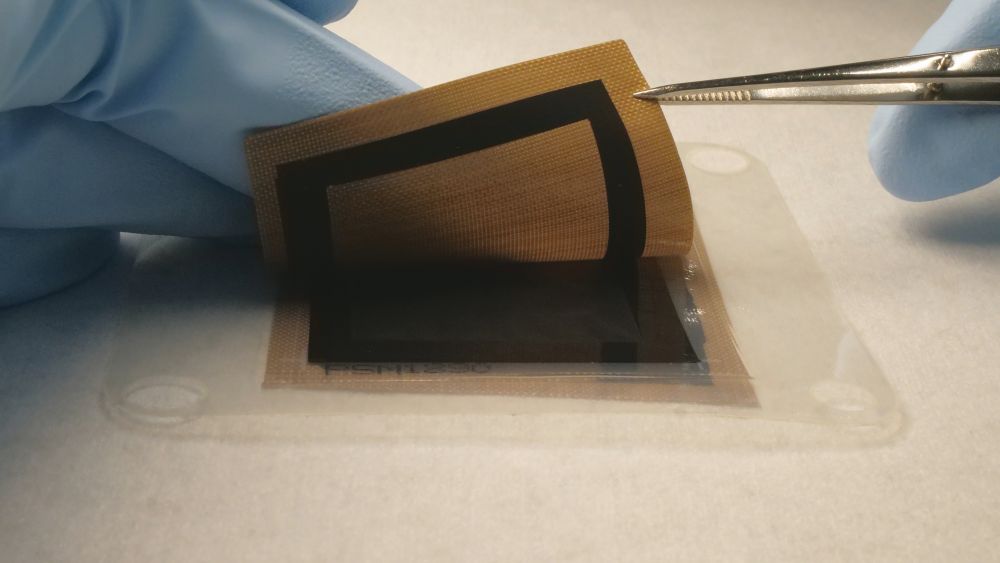

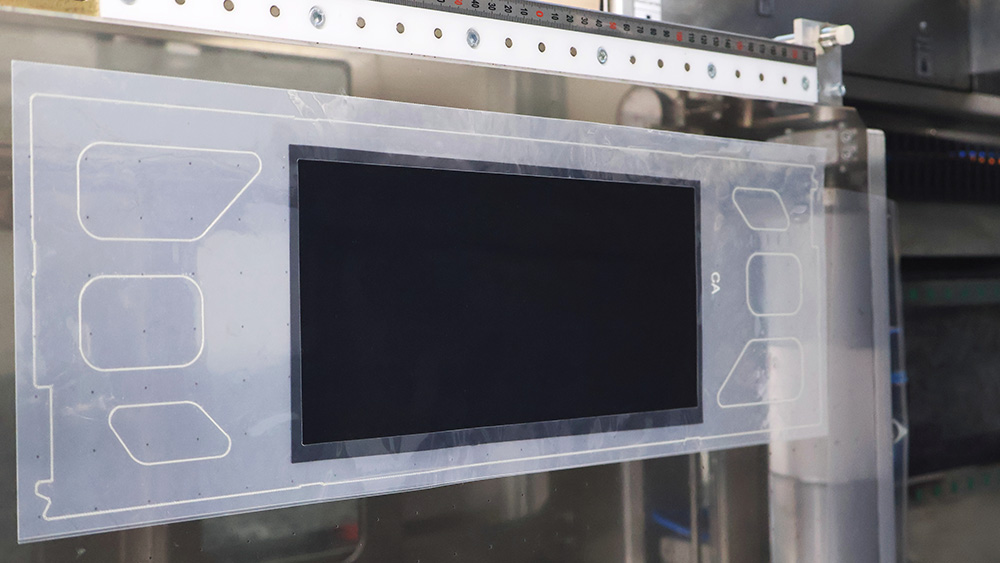

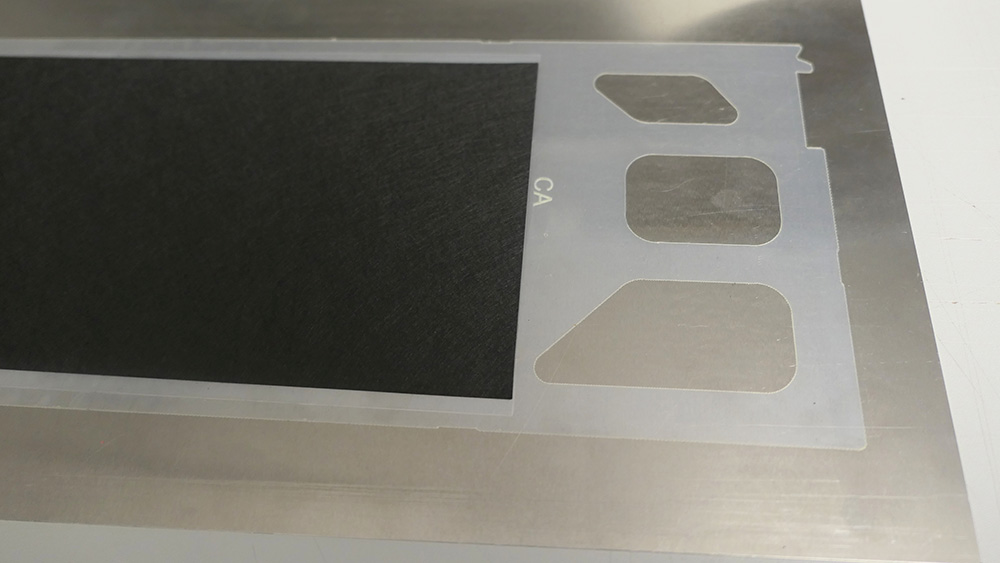

Our production research covers the entire value chain, from catalyst powder up to a full-scale 7-layer MEA, including quality control. We investigate the impact of process design and parameters, materials and component architecture on the cost, quality and performance of MEAs. We focus on laboratory-scale manufacturing processes with well-defined conditions - typically with sheet-to-sheet production - as well as industrial-scale processes such as roll-to-roll for mass production.

With our production research on MEA, we want to support, optimize and accelerate the establishment of industrial mass production.

We offer:

- design of membrane electrode assemblies

- evaluation of machines, components and materials (raw materials, pastes and inks, membranes)

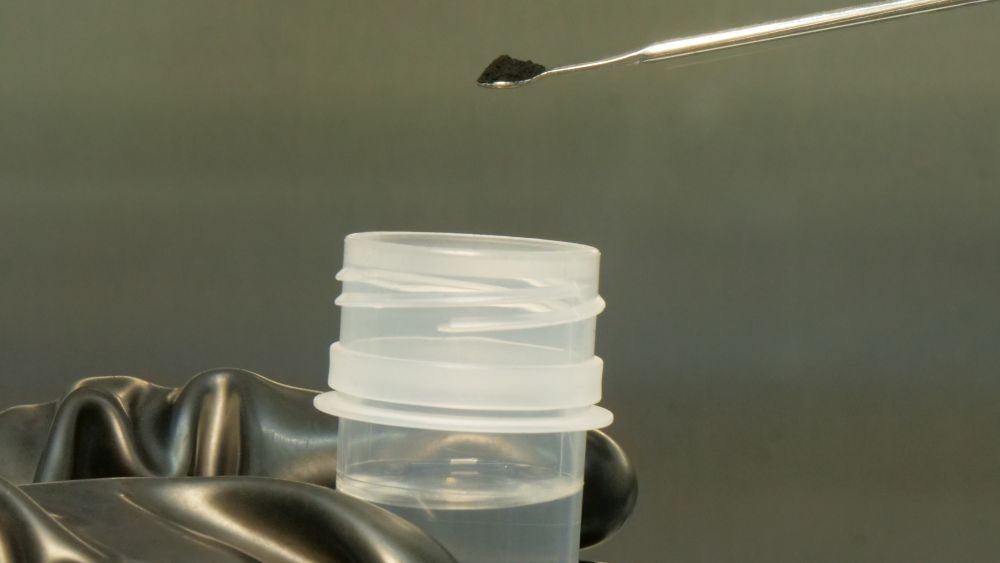

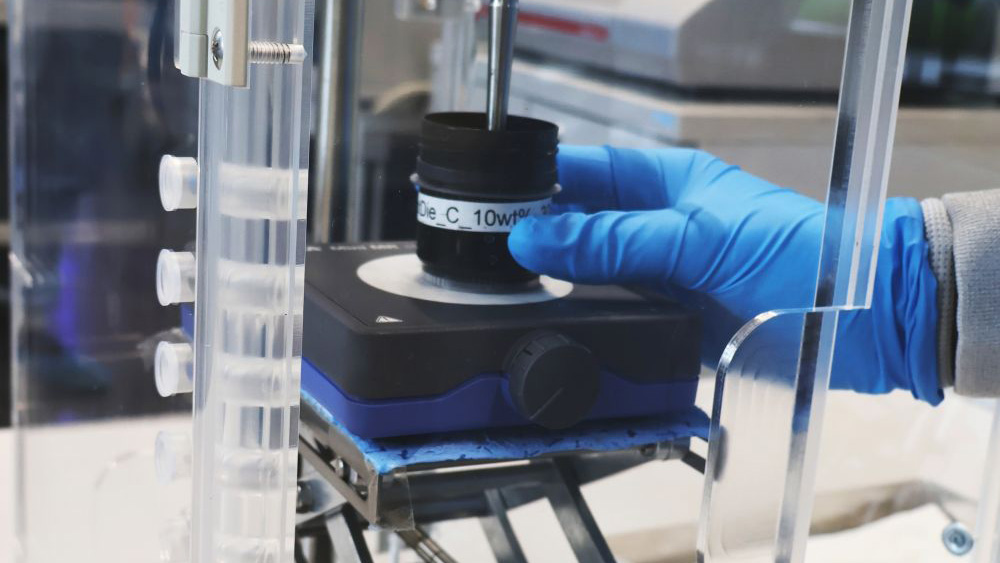

- development of pastes and inks, including homogenization and characterization

- development of processes and quality assurance methods along the entire MEA value chain

- ex-situ and in-situ characterization of layers and cell components

- techno-economic evaluation of production processes

Your benefits:

- Our many years’ experience in industry-related process technologies, from catalyst powder to membrane electrode assemblies, ensures a high level of confidence in the transfer of our results to your production process.

- We can offer you the testing of new materials, components, designs and processes without any disruption to your production.

- We manufacture components in small batches for testing purposes when the batch size is too small for industrial facilities.