In our "Lab Battery Testing", we provide performance testing for battery cells and systems regarding efficiency and effectiveness, aging tests as well as safety and reliability tests.

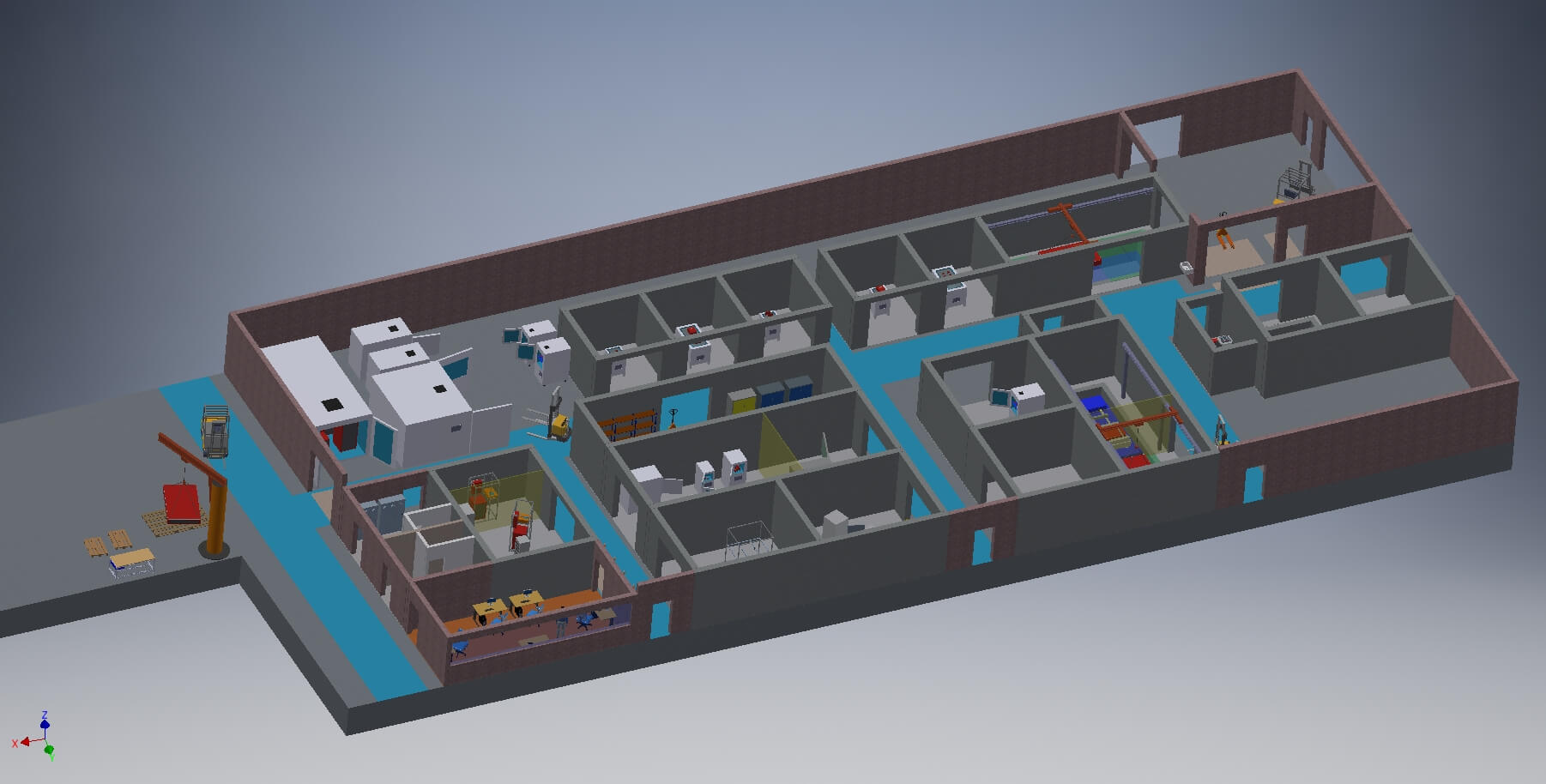

Lab Battery Engineering, Production and Testing

Our Services Include:

- Battery test facility for testing small and large size battery cells up to battery systems

- Battery aging: calendaric and cyclic

- Performance: efficiency and effectiveness

- Reliability under a wide range of operating and aging conditions

- Validation of technical and functional safety

- Development and evaluation of methods to prevent thermal runaway and propagation

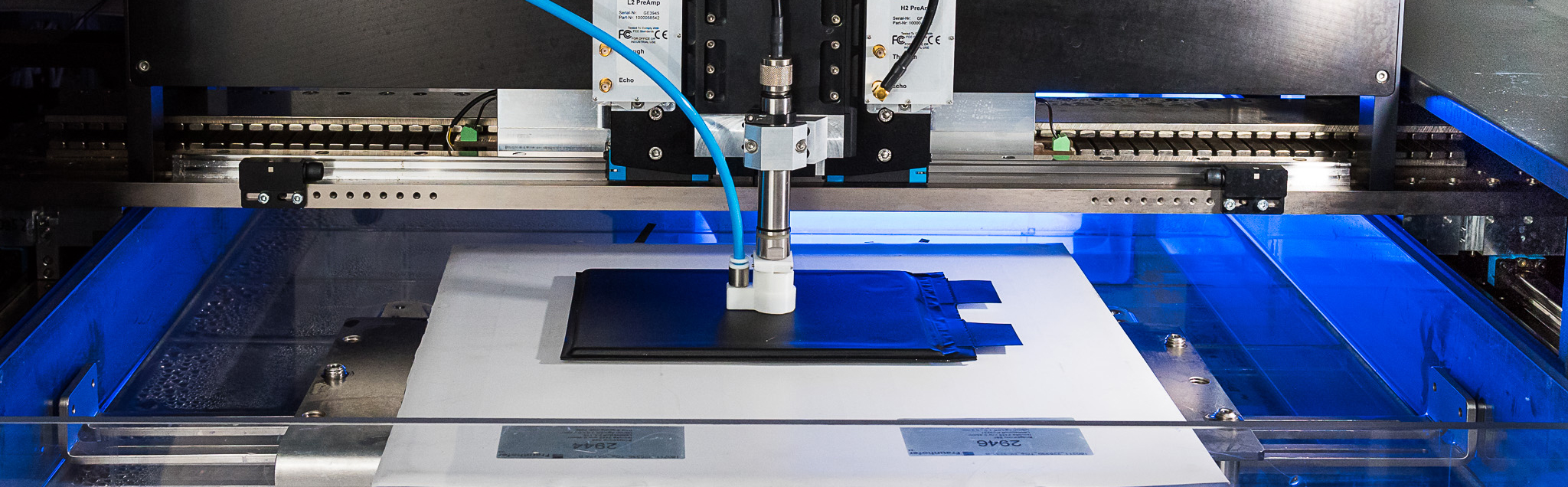

- Non-contact quality determination and assessment in battery cell production

- Non-destructive defect localization in battery cells

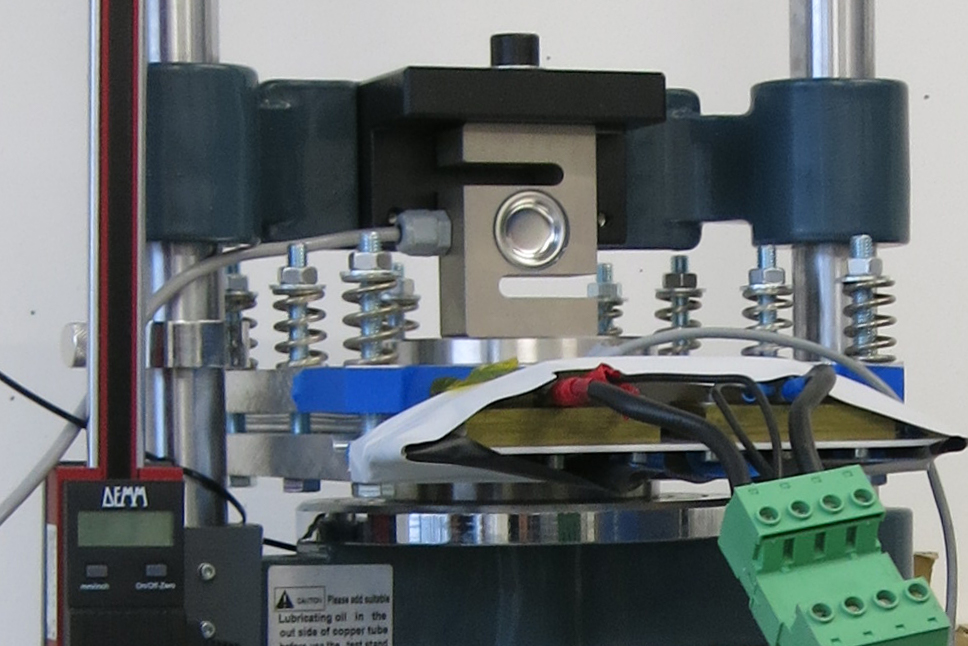

- Mechanical measurement and evaluation of battery cells and modules under pressure/compression

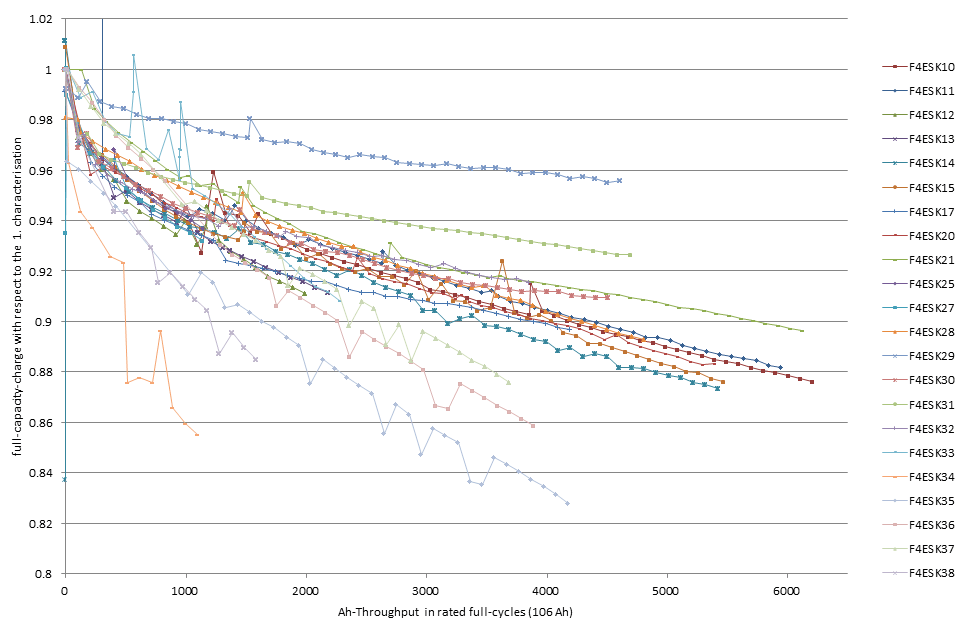

Aging Studies

For the investigation of aging and lifetime of battery cells and battery systems, we offer long-term tests with our equipments for cells, modules and systems at different voltage levels. These include both cyclic and calendar aging analysis as well as determination of the application-specific remaining useful lifetime. The most important parameters are the change in capacitance, internal resistance, heat dissipation and mechanical expansion. We provide scientific support for the tests and advise you on the test design.

Our laboratory equipment includes battery testers for cells, modules and systems, impedance spectroscopy and calorimeters. The tests are carried out in the climatic chamber or in air-conditioned rooms according to standards or customer requirements.

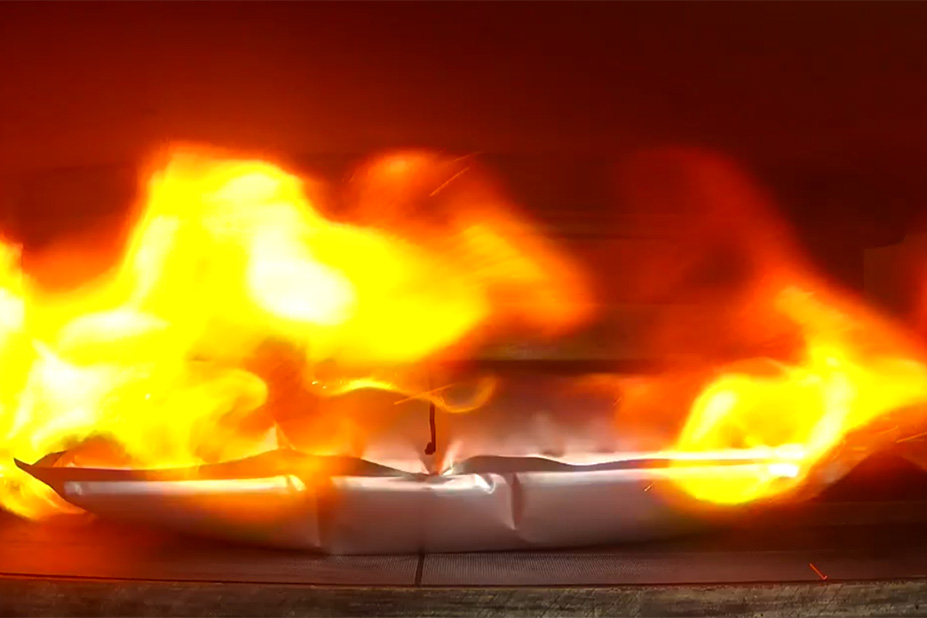

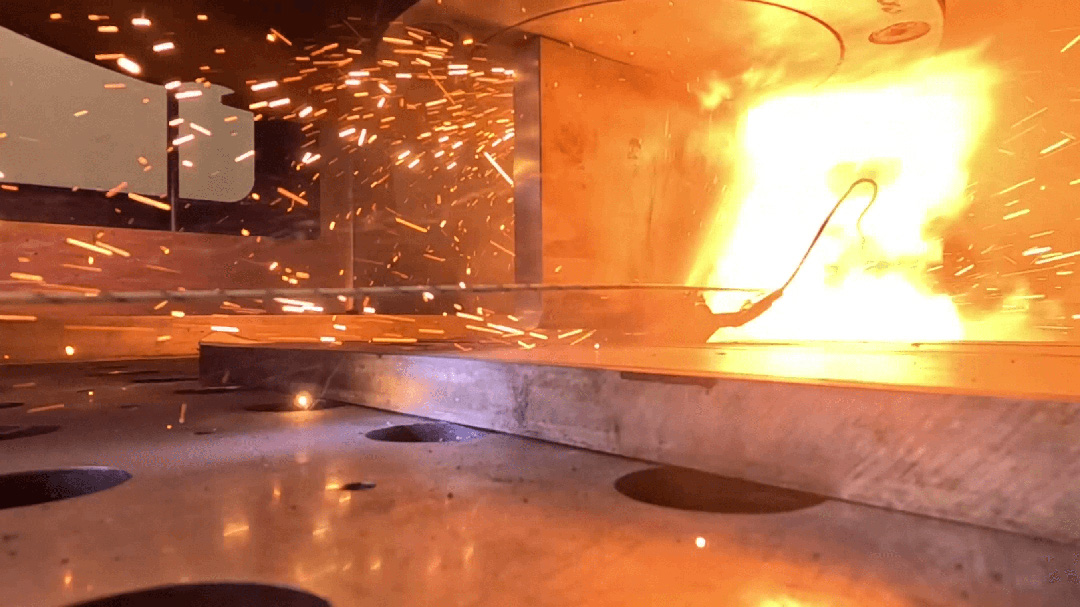

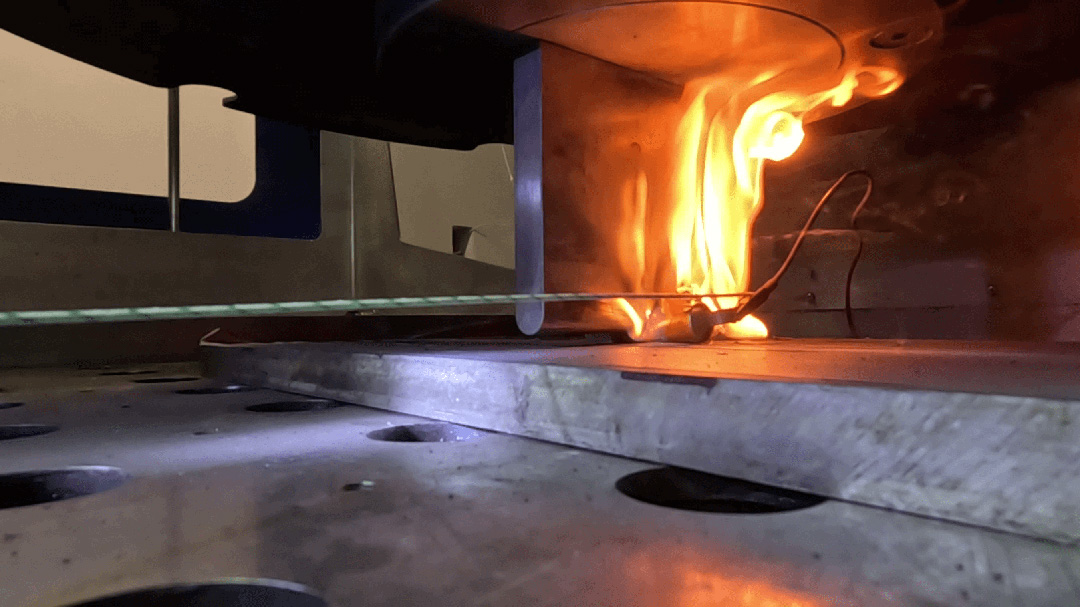

The range of services offered by our laboratories also includes destructive tests using mechanical, electrical and thermal mishandling. For this purpose, electrodynamic shakers, separate shockers, crush, short-circuit and nail penetration tests are available. These tests can also be thermally superimposed.

Characterization, Testing and Destructive Testing of Batteries for Quality Assurance Purposes.

With the continuous rapid development of the battery market, especially in mobile and stationary applications, the need for repeatable examination and testing of cells and systems continues to increase significantly. Flaws in battery design (both at cell and system level) can lead to either reduced performance and financial losses or even critical damage and accidents. Established test methods and novel characterization capabilities in the test lab can identify defects at the cell level as well as in the system structure and in the system design at an early stage.

To pursue this goal, we offer battery testing from cell to system level, according to customer specifications or according to established standards (e.g. UN38.3, IEC 62133, IEC 62619; IEC 62841). Furthermore, we provide support to our customers in the research of aging effects and in the development of application-oriented measures for lifetime optimization. Our modern equipment guarantees a reliable and safe operation of the battery tests.

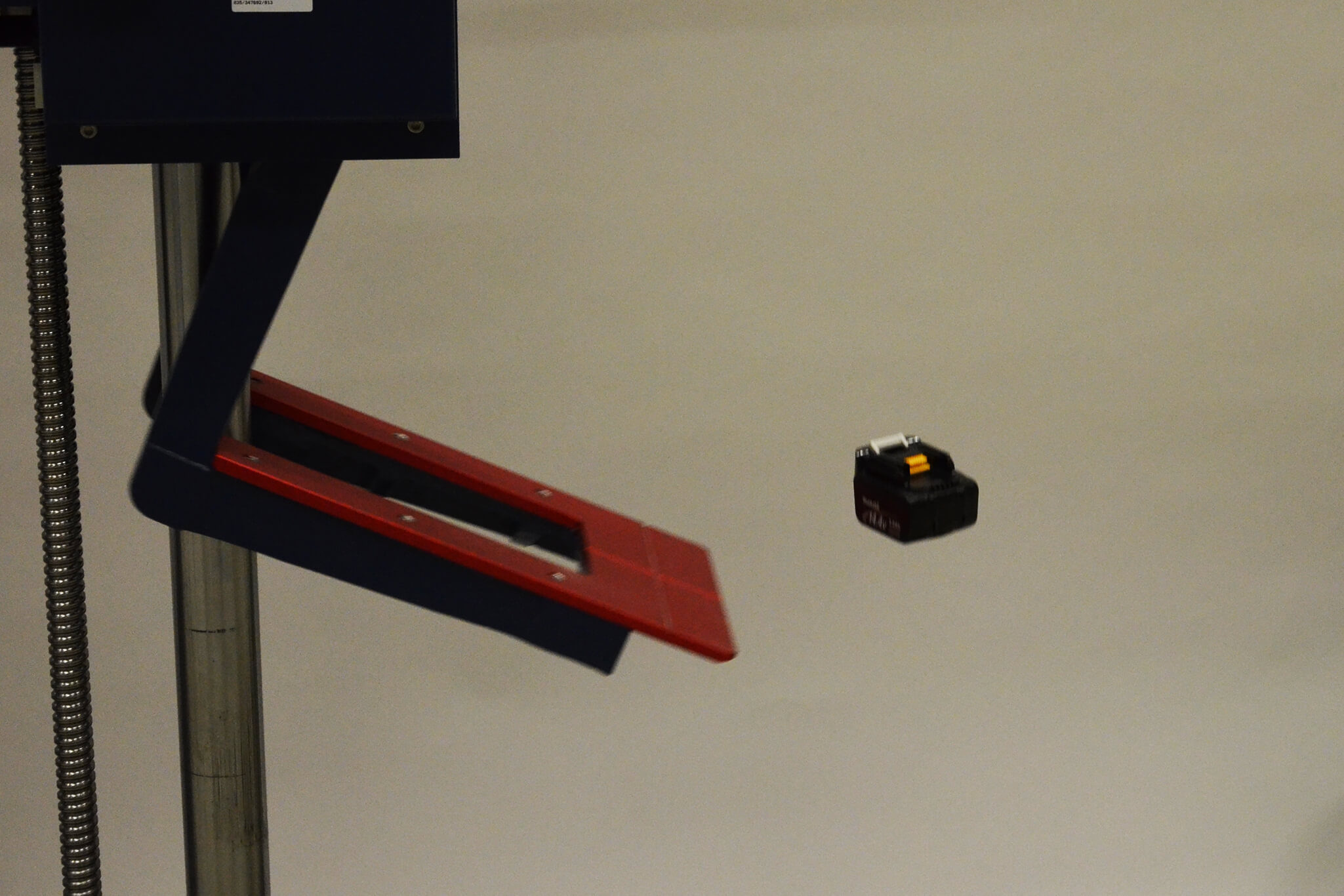

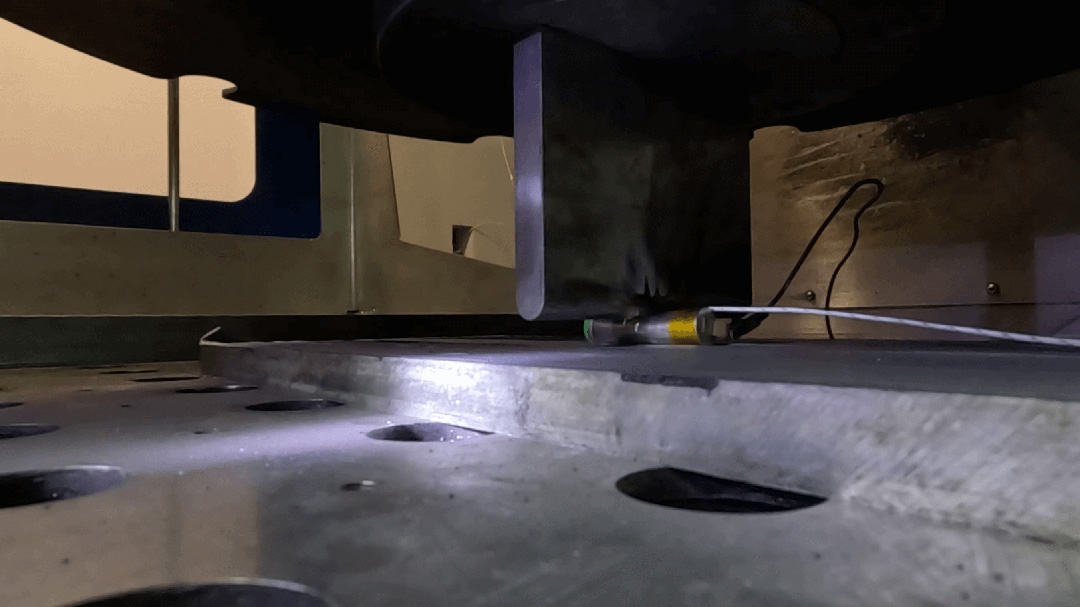

Crush Testing: Destructive Testing to Optimize Battery Safety

With our battery tests, we examine various scenarios to which batteries are exposed during their use. We place a special focus on situations that deviate from everyday use in conformity with the intended purpose. For example, a crush test can be used to test the penetration of a foreign object into a battery as well as the crushing and bending of a battery. Such a test can provide important information about battery behavior in the event of accidents and mishandling. Especially when used in e-vehicles, the issue of battery safety is of crucial importance.

By means of our detailed analyses, we are able to provide battery manufacturers with valuable assistance in optimizing battery safety.

By using customizable crush profiles, we can perform standard tests and - in addition - flexibly tailor our tests and measurements to the specific requirements of our customers. During a crush test, with up to 32 voltage and temperature channels, accurate monitoring of the DUT can be ensured. Various performance and safety parameters can be determined: Maximum penetration depth as well as maximum compressive force before thermal breakdown and point of stress breakdown.

Quality Determination and Evaluation of Battery Cells in the Production Process

Quality control for reliable and high-quality battery cell production is a complex task in which a whole range of relevant influencing variables must be taken into account. The quality of battery cells is reflected in a wide variety of parameters such as mechanical stability, capacity, performance or service life. The reasons for this are the variation in material quality, but also in production processes such as mixing, coating, assembly and formation. This can lead to high scrap rates.

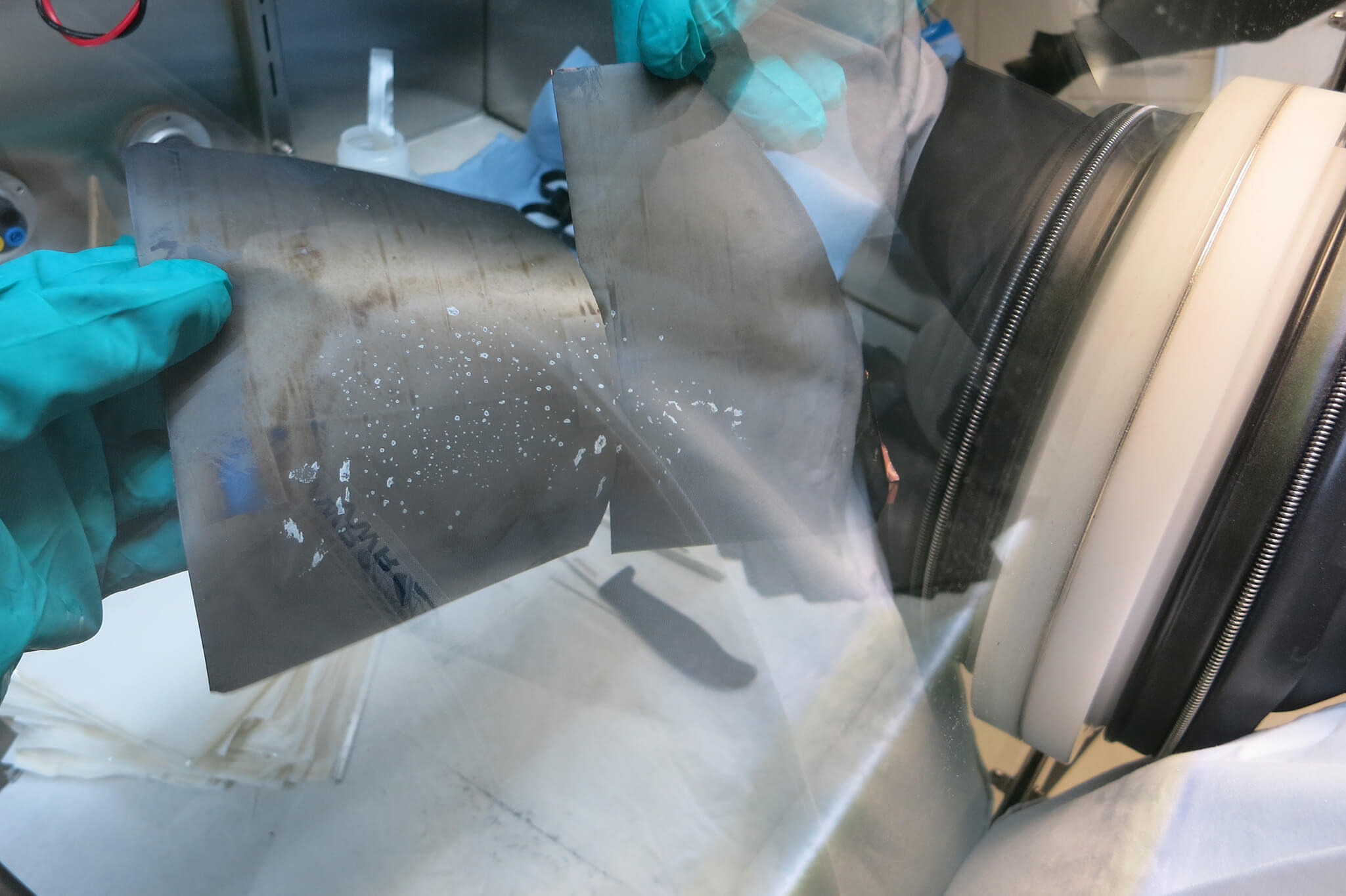

To significantly reduce scrap, production facilities need real-time feedback from the process. We focus on non-contact measurements to locate defects. This enables end-of-line quality assessment of battery cells. In addition to quality determination and assessment in cell production, our measurements and processes are particularly applicable in the context of inspection of incoming goods for battery systems.

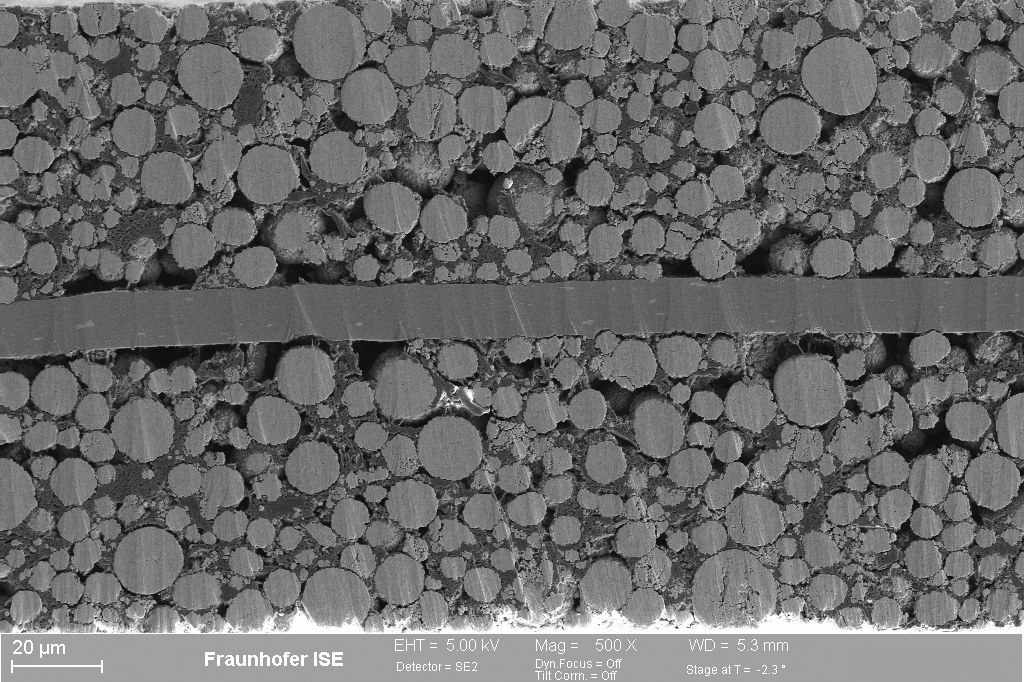

The non-contact quality control and assessment helps to identify potential optimization steps at an early stage of production, to minimize reject rates and thus to reduce production costs. To this end, we are developing methods for non-destructive quality control and data-based quality assessment of battery cells that are suitable for use in production lines, for example as part of the project "OrtOptZelle" funded by the German Federal Ministry of Education and Research (BMBF) in cooperation with RWTH Aachen University. In our battery test laboratories, mechanical, optical, acoustic and electrical methods are used to characterize batteries. Subsequently, these methods are validated by post-mortem analysis, which includes cell opening, characterization of cell components using microscopes, surface and chemical analysis. These results are used, for example, to help optimize battery performance and lifetime through targeted compression on battery cells.