The new EU Battery Regulation, which came into effect at the beginning of 2024, obliges battery manufacturers to use certain staggered proportions of recycled active materials (lithium, nickel, cobalt or lead) in new batteries from 2028.

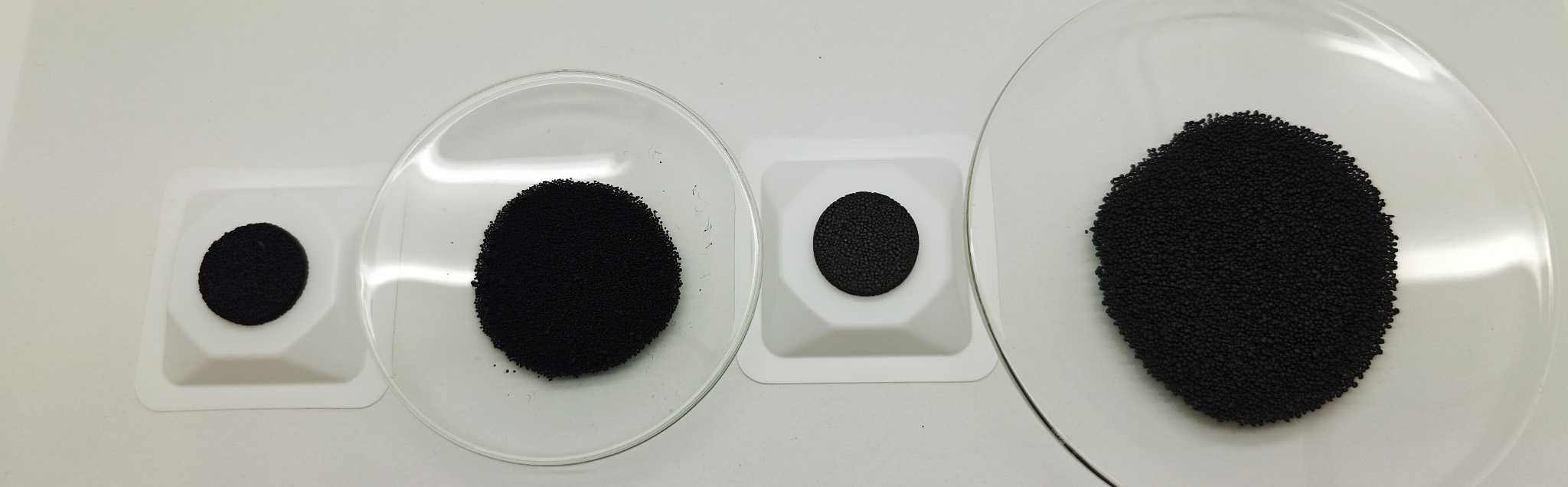

Using various mechanical, chemical and thermal treatment methods, we can extract materials from production waste or aged cells very flexibly in order to recycle them according to their intended use and, if necessary, refine them further. We focus not only on lithium-ion technologies, but also on sodium-ion and zinc-ion technologies.

In our characterization laboratory for battery materials, we can fully analyze recycled materials such as active materials. With our established process technology, we can produce electrodes and cells from the recycled materials on a coin or pouch cell scale and then validate them electrochemically.