Advantages of the Matrix Shingle Technology

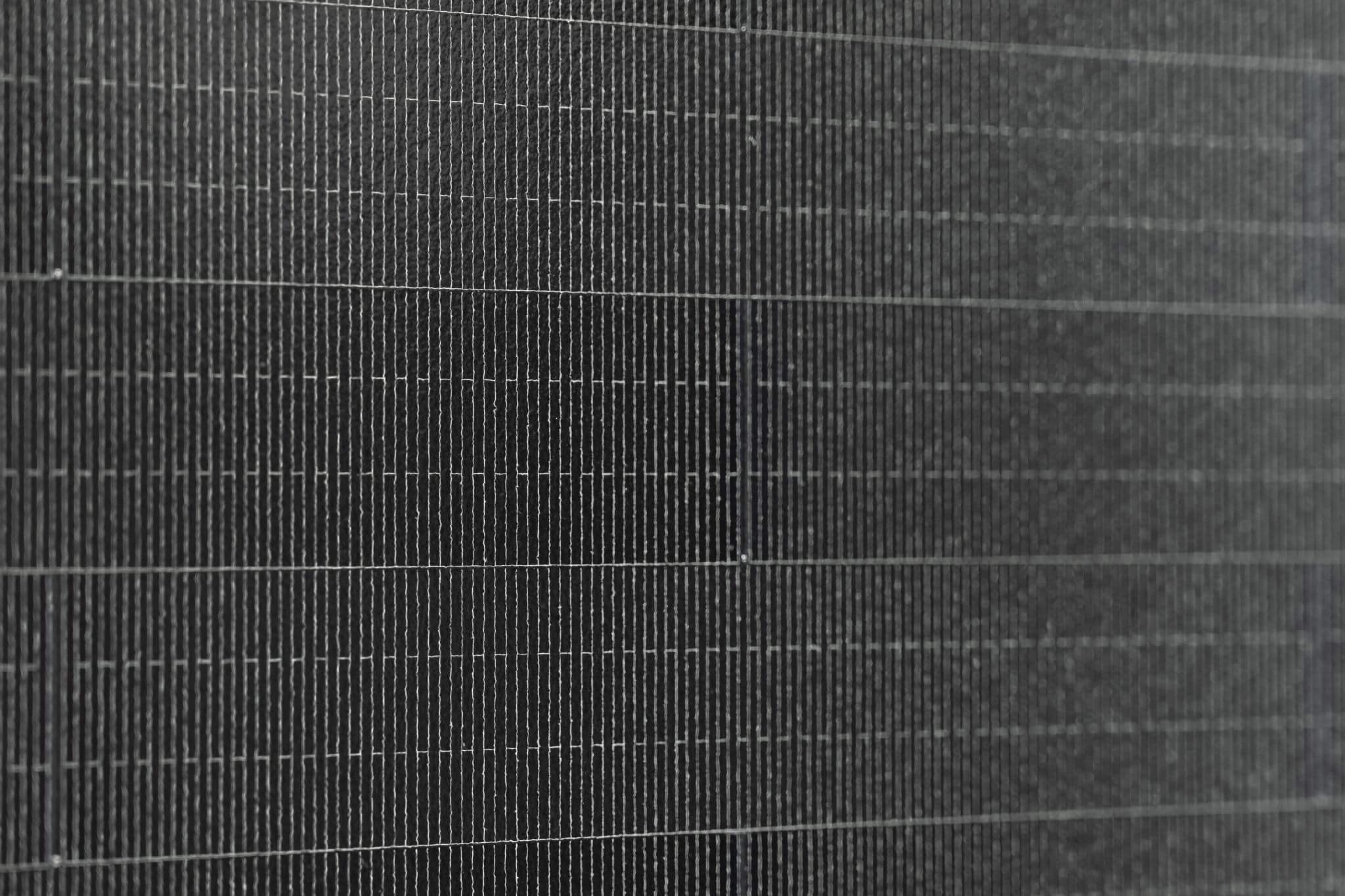

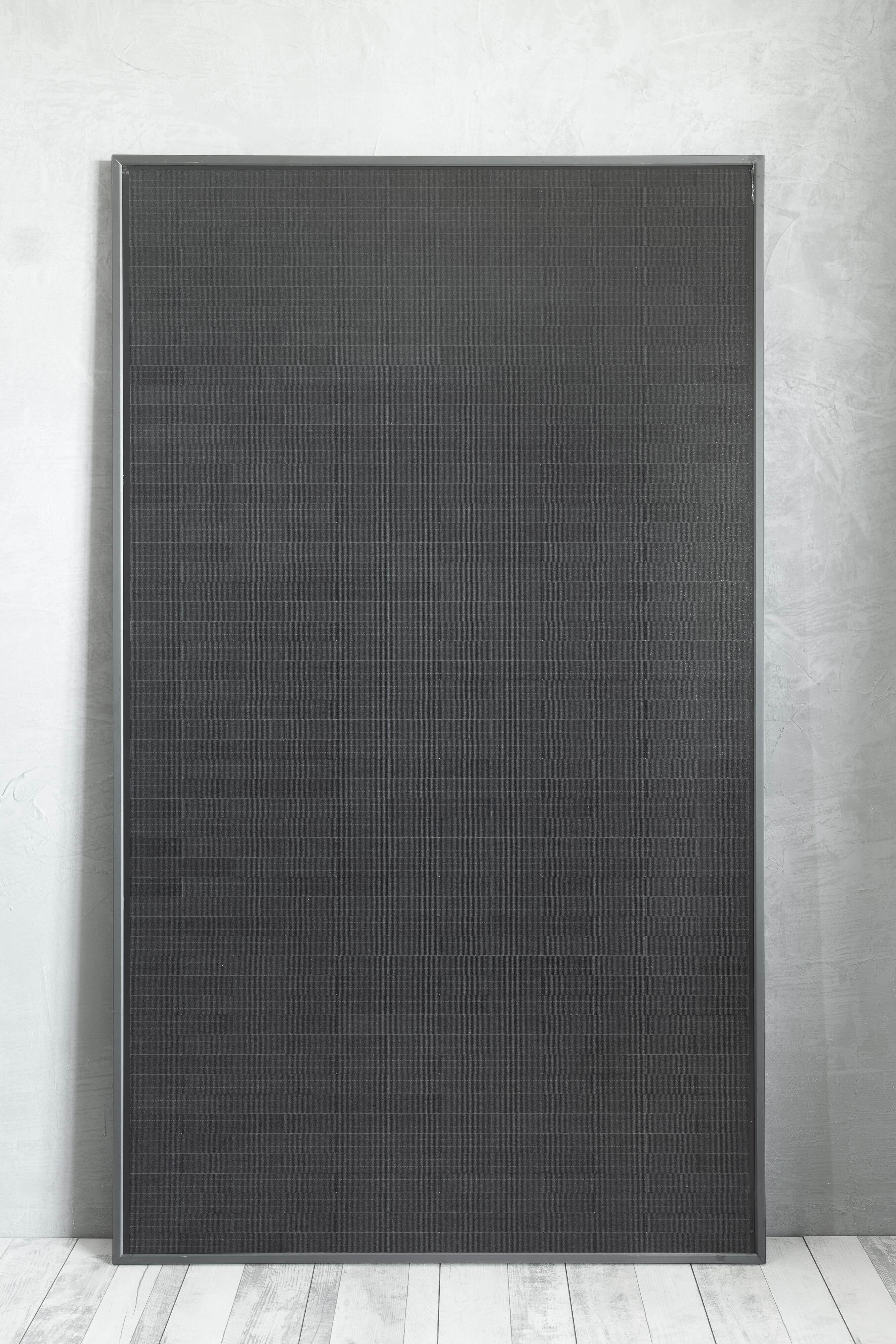

With the matrix interconnection, the area can be optimally utilized by staggering the shingle solar cells laterally; in addition, a very homogeneous appearance results. The cells are electrically connected in series and simultaneously in parallel. This network of interconnections ensures that in the event of shading, the current flows around the shaded areas. With conventional cell interconnection the entire string is affected.

- 2 - 6 %(relativ) higher module efficiency than conventional half-cell modules (maximum area utilization, low resistance losses)

- Homogeneous appearance

- 100 % lead-free cell interconnection

- Excellent module reliability

- Flexibly adaptable to building and facade geometry

- Up to 110 % more power in partial shading than conventional half-cell modules

- Manufacturing costs comparable to ordinary soldered joints

Our R&D-Activities Include:

- Product Development

- Prototyping and Pilot Line

- Test and Certification

- Custom Configured Shingle Strings or Matrices

- Support on Cell Technology Upgrade

- Workshops

With their high efficiency, matrix shingle modules offer maximum yield on a limited amount of space. If modules are integrated into the envelope of vehicles or buildings, not only efficiency but also a high power yield in the case of partial shading, a visually appealing appearance and easy scalability of the module size are required. Fraunhofer ISE has developed the matrix shingle technology especially for such applications.

A conductive, lead-free adhesive joins the solar cells gently, reliably and with high conductivity. The matrix shingle interconnection of silicon solar cells offers a homogeneous overall appearance due to the completely covered module surface, which can be optimally integrated into vehicles or buildings in a creative way. In matrix technology, cell strips are connected to each other in a staggered shingle technique, in the pattern of masonry.

Individual Coloring

The modules can be produced in different colors with high color saturation using the MorphoColor® coating developed at Fraunhofer ISE. The transmission of solar radiation and thus the efficiency of the colored modules is over 90 % of the value of comparable modules. The solar cells underneath are virtually invisible. This opens up a wide range of design options for architects and vehicle manufacturers.

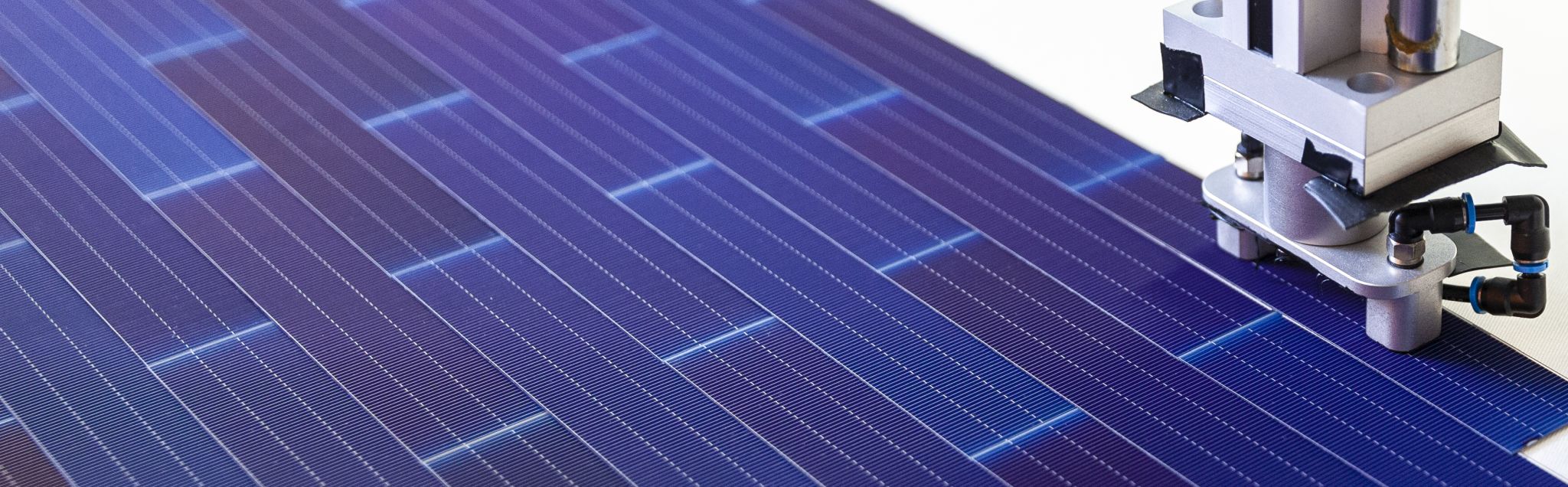

Production in the Novel Industrial Shingle Matrix Stringer

At Fraunhofer ISE's Module-TEC, we have a fully automated matrix shingle stinger from M10 Industries AG for automated and industry-oriented production. The stinger was developed in the publicly funded joint project “Shirkan” and can produce solar cell matrices in flexible shapes. The machine concept of M10 allows the interconnection of 12,000 shingle solar cells per hour. All common solar cell formats and technologies can be processed. We can optimize and precisely adjust the amount of adhesive applied, the size of the shingle overlap and the duration and temperature of the adhesive curing. The solar cells are connected in series and simultaneously in parallel to create a cell matrix of any size, which reacts particularly robustly to partial shading during operation. We produce prototypes as well as small series according to your design ideas and are happy to support you in the development of new module concepts.