Thermal processes are essential in solar cell production. The process quality is significantly determined by the temperature and its temporal course, and therefore, precise temperature regulation (or control) plays a decisive role in achieving high quality processing. For this reason, infrared (IR) emitters are often used as heat sources in industrial furnaces, in which large share of the required power is used to heat the chamber walls and the process atmosphere. The thermal mass of the process chamber and the IR emitters are the main factors that determine the achievable heating and cooling rates for a stationary substrate. Because the chamber typically has a high thermal mass, only slow temperature changes are possible. In solar cell production, full area laser irradiation of the target surface serves as an alternative energy (or heat) source to the IR emitters. In this case the target substrate is heated exclusively by laser absorption, which results in a selective heating of the substrate. The heating and cooling rates are essentially determined by the thermal mass and optical properties of the target substrate. This processing technique allows a silicon carbide (SiC) substrate to be heated to 1700 K with heating rates of 600 K/s under atmospheric pressure and room temperature, for example Additionally, the direct absorption of the radiative energy into the target substrate allows for a sophisticated temperature control.

Laser Thermal Annealing

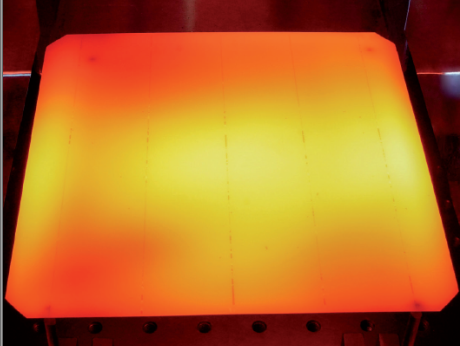

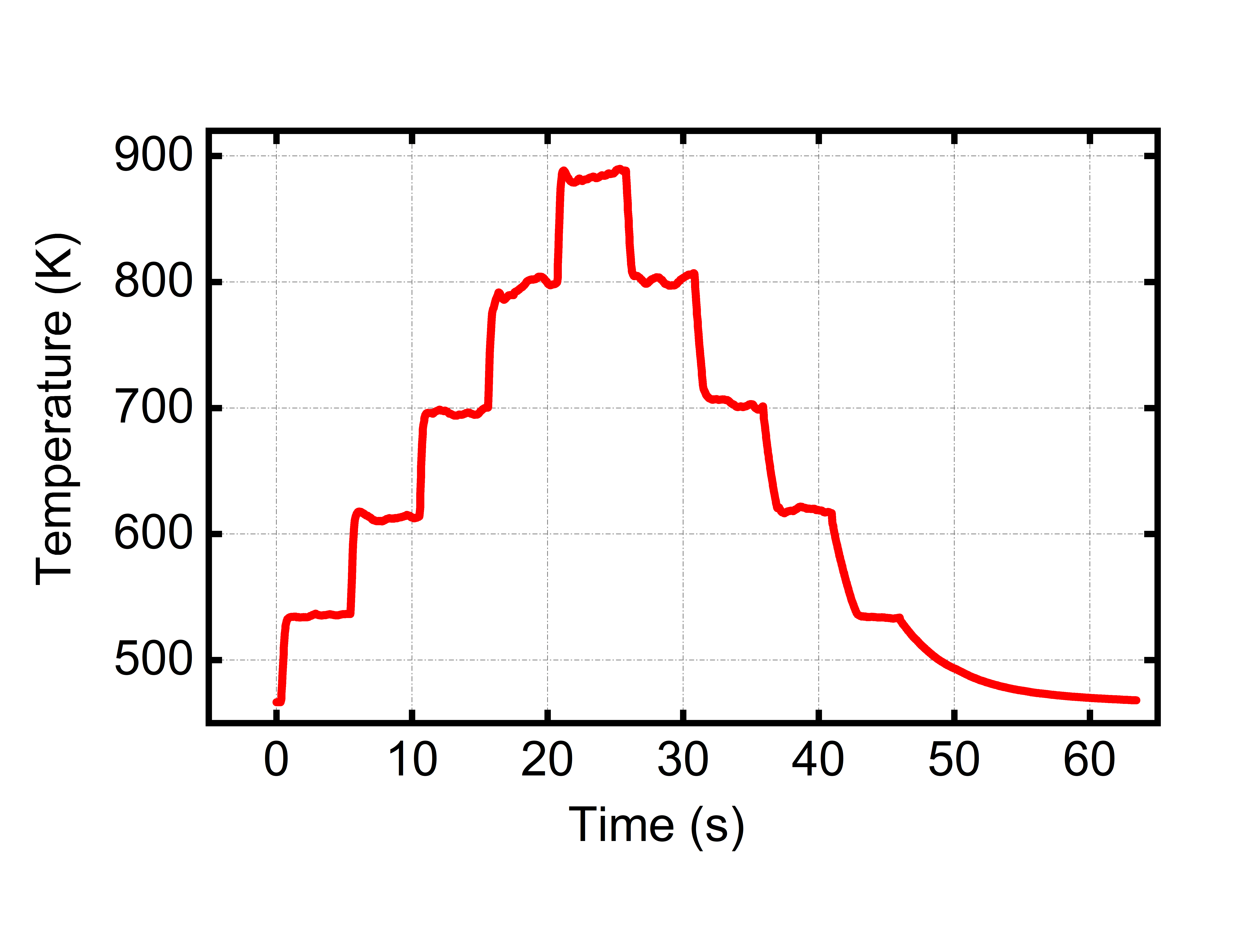

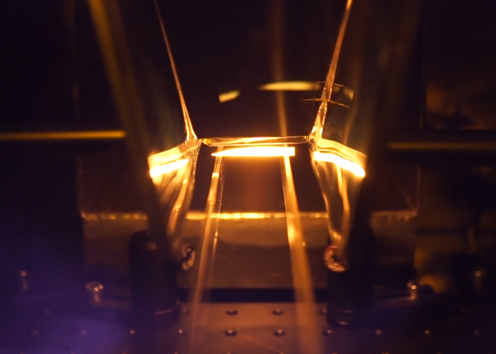

High-temperature annealing step for a silicon carbide (SiC) substrate in the Rapid Thermal Processing (RTP) setup at Fraunhofer ISE: irradiance up to 4000 kW/m²; heating rates up to 600 K/s; temperatures up to 1700 K.

A laser-based Rapid Thermal Processing (RTP) setup designed at Fraunhofer ISE is used to investigate and evaluate novel application areas for the full-area laser-based heat treatment. The research focuses particularly on heat treatments which benefit from heat input on the one hand and charge carrier injection on the other hand. A myriad of applications exist, which include heat treatments with complex temperature control and high-temperature annealing steps as well as a many applications in photovoltaics such as the regeneration of BO (boron-oxygen) defects or the suppression of LeTID (light and elevated-temperature induced degradation).

Possible applications of the laser-based RTP technology

- Heat treatments with complex temperature control and high-temperature annealing steps

- Annealing steps, e.g. for edge passivation of half cells

- Light soaking at moderate temperatures of SHJ solar cells

- Boron-oxygen (BO) regeneration

- Simultaneous BO regeneration and contact annealing of Ni/Cu/Ag plated contacts

- Suppression of light and elevated temperature induced degradation (LeTID)

Our service offer:

- Development of innovative process solutions

- In-depth analysis of resulting electronic, optical and functional properties

- Development of component prototypes

- Thermal process simulations