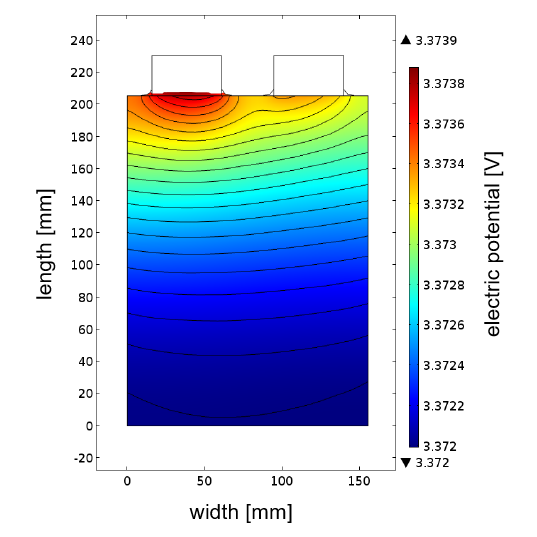

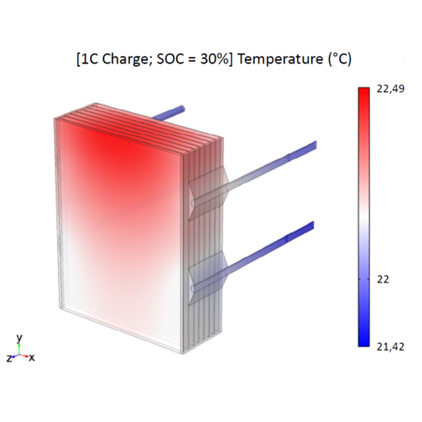

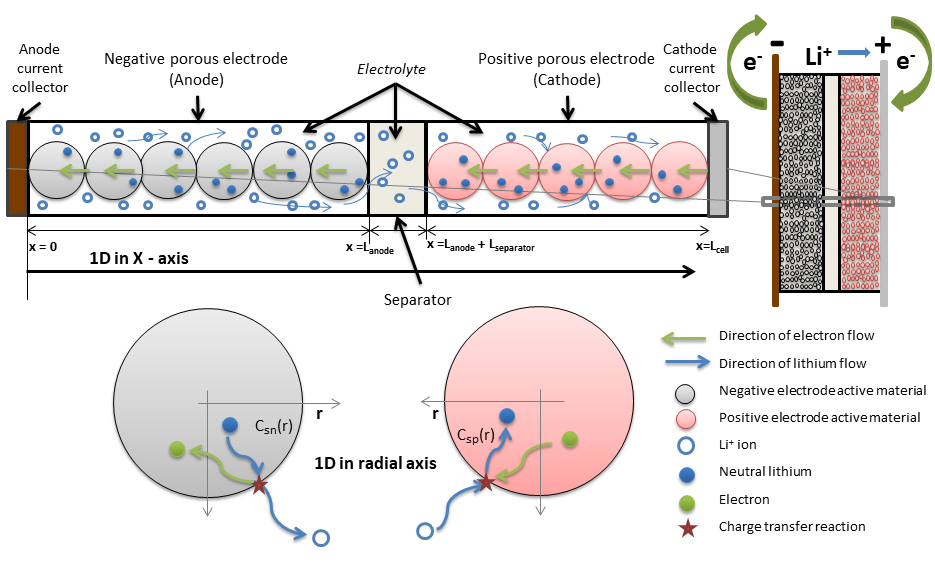

Electrical simulations are used at Fraunhofer ISE in various fields. In addition to the simulation of inhomogeneities in PV modules, the simulation of batteries - on cell and system level - as well as their production processes is a main focus.

Batteries are rapidly gaining in importance for the success of the further expansion of fluctuating renewable energies (PV, wind). Also they represent the foundation for the transport transition, as a highly efficient mobile storage system. The complex behavior of the electrical performance and its sensitive dependencies on temperature, constructive, mechanical and chemical parameters as well as, in particular, the aging mechanisms and their interactions are the subject of extensive scientific and technical research. Modeling and simulation of batteries as well as their production processes (e.g. welded joints or interface formation) are substantial tools for their efficient processing. The scope of time-consuming tests in the laboratory, which are associated with high safety precautions, can thus be significantly reduced, enabling cost-optimized development towards the product (time to market).