Short innovation cycles require rapid design changes to PV modules. In order to operate successfully in the fast-growing and volatile markets for power plant and rooftop modules, it is necessary to always reflect the current state of the technology. Testing these efficiently and implementing the necessary verification processes in a time-effective manner is essential.

Fraunhofer ISE has stood for quality and innovation for over 40 years. Through close cooperation with leading equipment and material manufacturers from the entire PV value chain, the Module Technology department has a broad spectrum of knowledge and experience from which you can benefit.

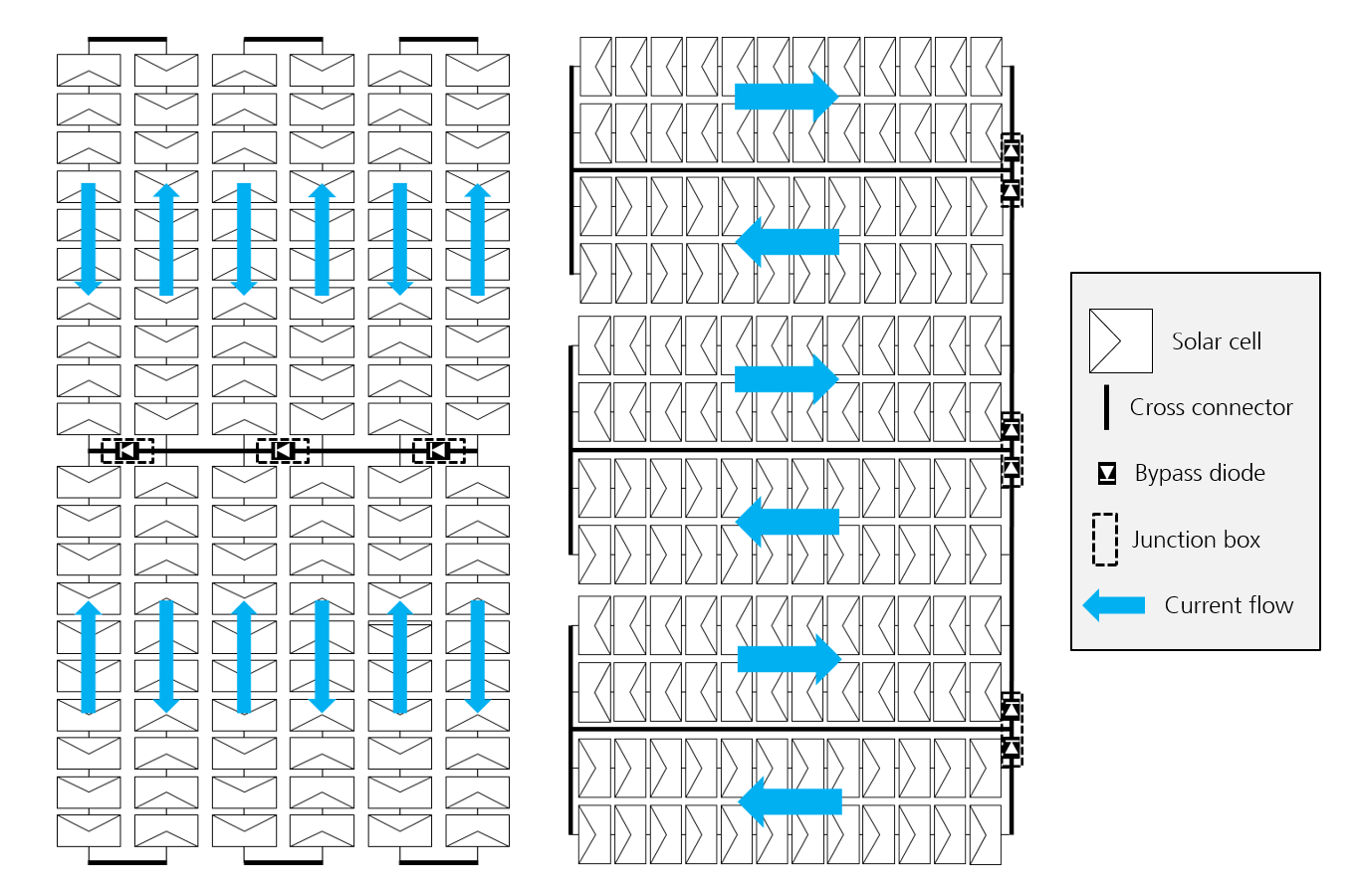

Due to capacity bottlenecks, R&D and production often compete with each other on a day-to-day basis. We offer you the opportunity to outsource your R&D to us. We are happy to support you in developing and testing new material combinations and implementing them as prototypes or small series. You benefit from our experience and expertise in new processes and materials for the successful interconnection and encapsulation of new cell formats and technologies.

Fast internal processes with accredited test laboratories enable the development of new modules and their certification to be carried out in parallel. This saves time and money in the development of new module concepts. The result is an early start to the planned series production.