Sodium-ion battery (NIB) technologies are experiencing an increasing interest and offer an alternative to lithium-ion batteries (LIB) for both stationary storage and mobile applications. The high natural abundance of sodium itself and of the elements used for the active materials allows these batteries to be made from materials with good availability, low cost and less price volatility.

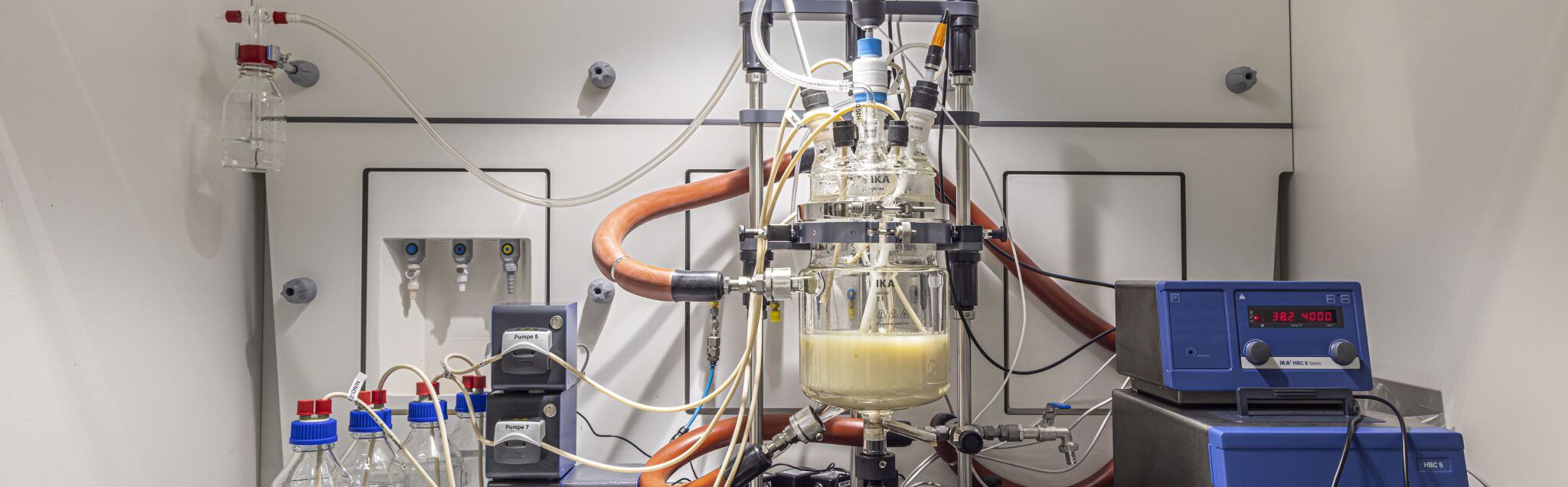

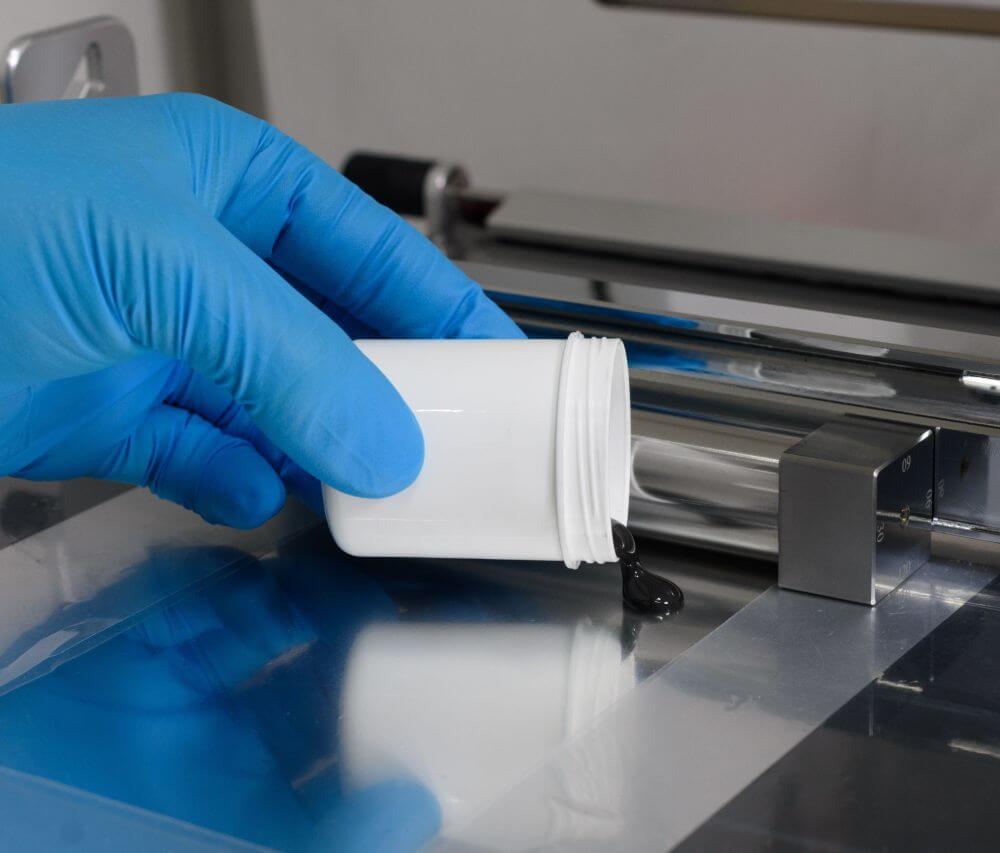

As NIBs operate in the same way as LIBs ("rocking chair principle"), a lot of knowledge and experience can be transferred. Particularly in the areas of active material production, electrode production and cell assembly, this technology can be used as a drop-in replacement, as it uses similar production processes to LIBs and can therefore be integrated into existing production lines without major adjustments.

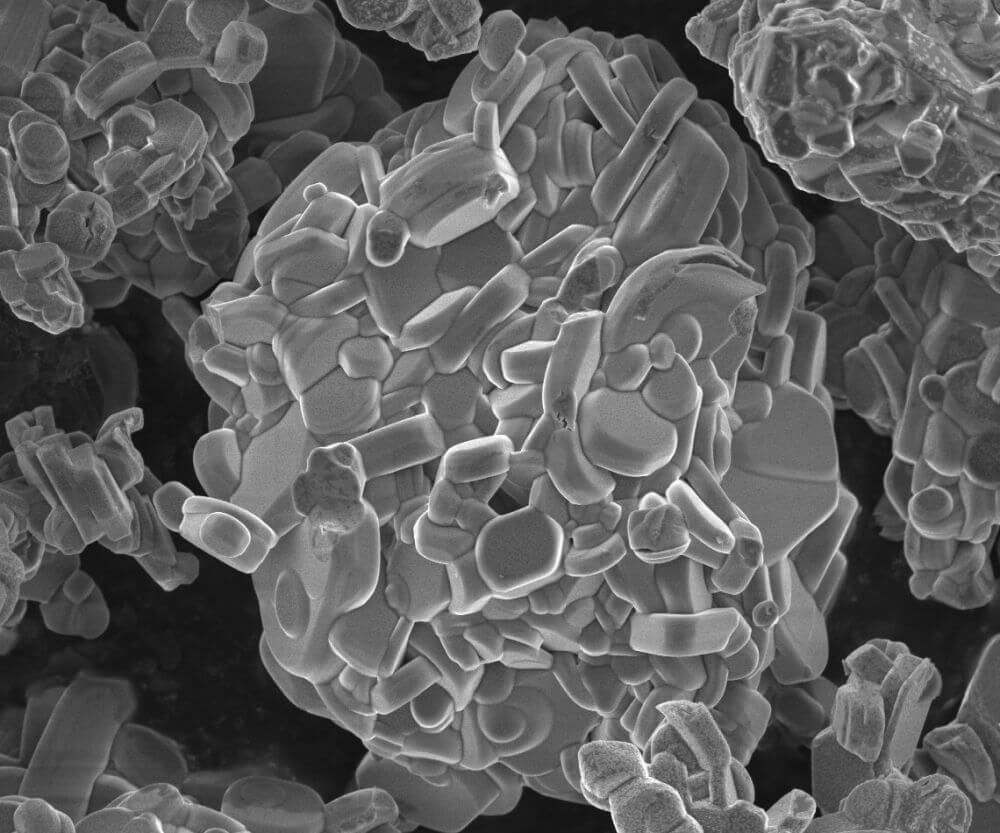

The size of the sodium ions, which are larger than the lithium ions, is a significant difference between the two technologies. This difference in size influences, among other things, the choice of active materials, which currently have a lower energy density than LIBs.

Overall, NIBs have great potential and, with further research and development, offer a sustainable and cost effective solution for storing energy.