| Duration: | 11/2019 - 12/2023 |

| Contracting Authority/ Sponsors: |

Land Baden-Württemberg, Ministerium für Umwelt, Klima und Energiewirtschaft |

| Project Partners: | Zentrum für Sonnenenergie- und Wasserstoff-Forschung Baden-Württemberg |

| Project Focus: |

HyFaB-BW - HyFab-Baden-Württemberg

Research Factory for Hydrogen and Fuel Cell Technology

The »HyFaB-BW« project creates an open, flexible platform for companies in the plant engineering, automotive and supplier industries in which technologies for component production and component qualification can be researched and tested with regard to the fuel cell membrane electrode assembly. This includes further topics such as the investigation of the interrelationship between the material composition of a component or its material structure and its operating behavior. In concrete terms, the project will generate findings that will enable companies to transfer their product developments to series-ready production, depending on the application and fuel cell type.

HyFaB is carried out by the Center for Solar Energy and Hydrogen Research Baden-Württemberg (ZSW) (focusing on the cell stack) and the Fraunhofer Institute for Solar Energy Systems ISE (focusing on the membrane electrode unit).

The fuel cell industry is about to be scaled up to industrial mass production up to an expected number of 200,000 stacks per year from 2030. The HyFaB project will prepare this upscaling with corresponding production research and accompany the market participants in their production development. Building on the understanding of the interrelationship between process, structure and operating behavior, the analysis and development of high-speed processes and the associated online quality assurance is carried out in the federally funded project "R2MEA". The other federally funded HyFab projects are investigating ink development for various coating processes ("TiKaBe"), the running-in processes of fuel cell stacks ("BI-FIT"), quality assurance in the series production of CCMs ("QUALLE"), the usability of alternative, PFAS-free materials for CCMs ("GIRAFFE"), and the specific development of a hydrocarbon-based CCM ("DirectStack2Scale"). The aim of the HyFaB research projects is thus to establish a platform for production research from component to stack manufacture, which will offer the fuel cell industry opportunities for contract and collaborative research with regard to series production, including quality assurance.

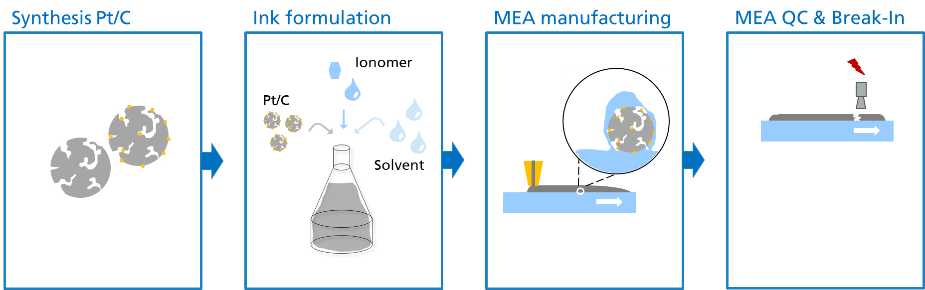

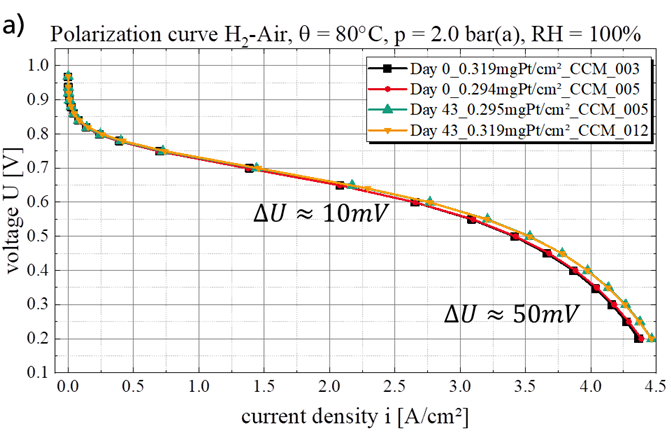

In the HyFaB-BW project, Fraunhofer ISE is focusing on the processes which concern the processing of the components catalyst powder, membrane, ionomer, frames and fiber mats, to form a complete membrane electrode assembly. The aim is to realize the process technologies relevant for these components on a laboratory scale and to clarify the relationship between the component composition and material structures as well as the operating properties of the components by means of extensive analytics (in-situ and ex-situ). For example, different material compositions in the MEA (consisting of catalyst powder, ionomer, solvent) combined with the different processes (hot pressing, cutting the CCM, laminating the subgasketsg) and different types of process control (e.g. process speed, temperature, injection pressure, etc.) can produce different product properties that are suitable for different applications. In addition, there is a wide range of processes known for the individual process steps (e.g. for coating alone processes such as slot die, screen printing, inject printing, etc.).