Zinc-ion battery (ZIB) technologies are attracting increasing interest in battery research, particularly in the field of stationary battery storage systems (SBS). ZIB technologies are well known in alkaline manganese batteries, which are used to operate a wide variety of small devices and are not rechargeable. The use of adapted electrolyte systems (e.g. with an acidic pH value) makes it possible to recharge the ZIB and thus use it as battery storage for the energy transition. The ZIB based on highly available, non-critical raw materials offers enormous potential for stationary applications as a safe, cost-effective, robust and environmentally friendly alternative to established lithium-ion-based battery technologies.

At Fraunhofer ISE, we are researching the following topics for ZIB technology:

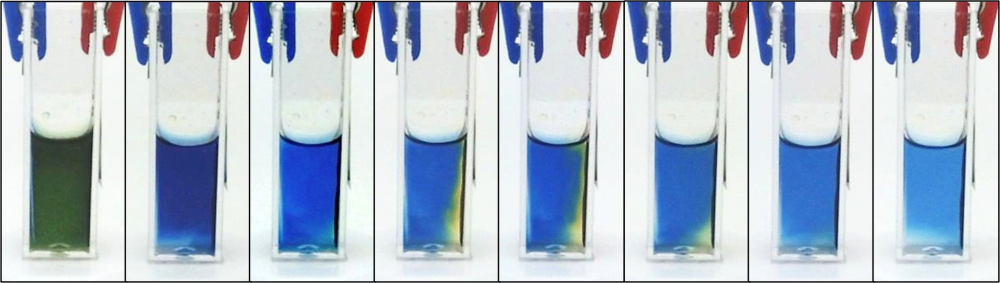

- Development and characterization of water-based electrolytes with additives and pH management for long-term stable operation of the battery cell

- Development and production of innovative battery electrodes with high layer thicknesses for water-based battery technologies based on dry coating processes, among others

- Characterization of battery cells using electrochemical methods and post-mortem investigations in our own characterization laboratory

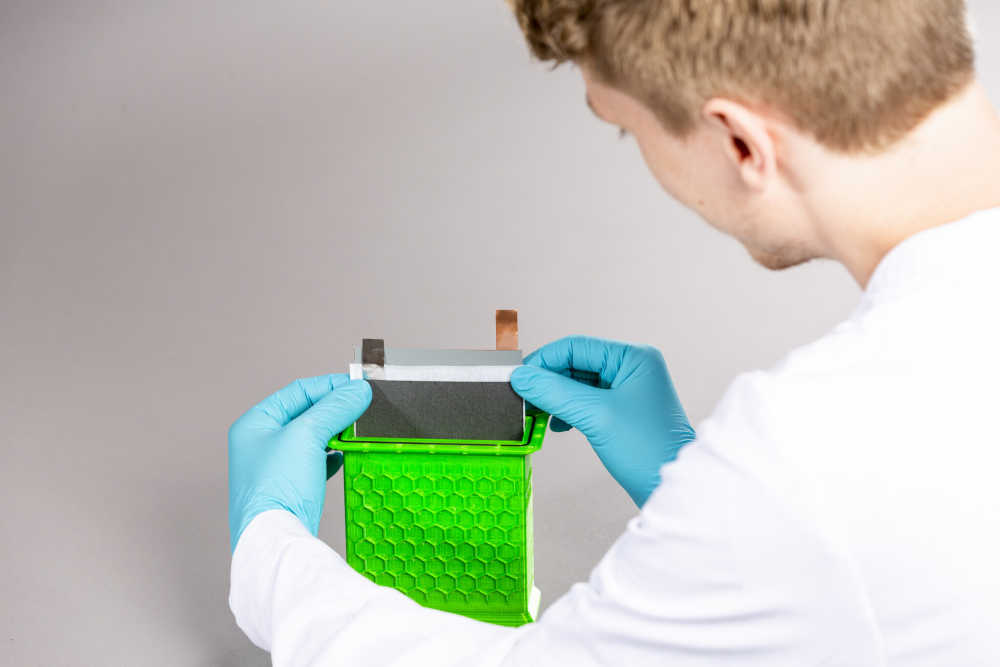

- Development, production and electrochemical characterization of battery module prototypes using innovative production methods (e.g. 3D printing)

- Support in project planning for R&D projects and data collection for techno-economic analyses of zinc-ion battery technology