Jahr

Year | Titel/Autor:in

Title/Author | Publikationstyp

Publication Type |

|---|

| 2026 |

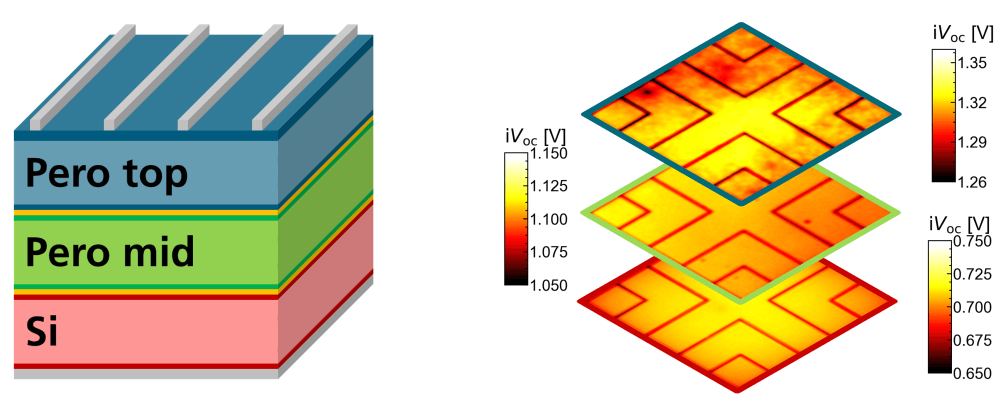

Imaging-Based Loss-Analysis for Perovskite/Perovskite/Silicon Triple-Junction Solar Cells

Fischer, Oliver; Heydarian, Minasadat; Heydarian, Maryamsadat; Schulze, Patricia; Borchert, Anna Juliane; Schindler, Florian; Glunz, Stefan; Schubert, Martin |

Zeitschriftenaufsatz

Journal Article

|

| 2026 |

Legend-Informed Symbol Recognition in Engineering Diagrams with Self-supervised Learning

Hain, Antonia; Gölzhäuser, Simon; Réhault, Nicolas; Brox, Thomas; Demant, Matthias |

Konferenzbeitrag

Conference Paper

|

| 2025 |

TOPCon Solar Cells Made of n-Type and p-Type Epitaxially Grown Silicon Wafers

Richter, Armin; Drießen, Marion; Rittmann, Clara; Vescovi, Giuliano; Richter, Maxi; Schindler, Florian; Benick, Jan; Weiss, Charlotte; Janz, Stefan |

Zeitschriftenaufsatz

Journal Article

|

| 2025 |

Light and Elevated Temperature Induced Degradation in Gallium-Doped Silicon: A Complete Parametric Description

Thome, Fabian; Kwapil, Wolfram; Schindler, Florian; Schubert, Martin; Garashli, Elvin |

Zeitschriftenaufsatz

Journal Article

|

| 2025 |

Water-Free PEDOT:PSS Formulation for Pb–Sn Mixed Perovskite Single-Junction and All-Perovskite Tandem Solar Cells

Loukeris, Georgios; Masood, Muhammad Fareed U Din; Pap, Leonie; Gillen, Audrey Elizabeth; Fischer, Oliver; Schubert, Martin; Günthel, Michael; Knäbbeler-Buß, Markus; Schuster, Henrik; Krossing, Ingo; Kohlstädt, Markus; Bett, Andreas W.; Würfel, Uli |

Zeitschriftenaufsatz

Journal Article

|

| 2025 |

Versatile implied open-circuit voltage imaging method and its application in monolithic tandem solar cells

Fischer, Oliver; Bui, Anh Dinh; Schindler, Florian; Macdonald, Daniel; Glunz, Stefan; Nguyen, Hieu T.; Schubert, Martin |

Zeitschriftenaufsatz

Journal Article

|

| 2025 |

Manifestation of Light- and Elevated-Temperature-Induced Degradation in n-Type Silicon: Initial Lifetime Improvement Due to Temporary Recovery

Hammann, Benjamin; Kwapil, Wolfram; Horzel, Jörg; Schubert, Martin; Schindler, Florian |

Zeitschriftenaufsatz

Journal Article

|

| 2025 |

Shingle Cell IV Characterization Based on Spatially Resolved Host Cell Measurements

Kunze, Philipp; Demant, Matthias; Krieg, Alexander; Tummalieh, Ammar; Wöhrle, Nico; Rein, Stefan |

Zeitschriftenaufsatz

Journal Article

|

| 2025 |

Hydrogen in Silicon Solar Cells: The Role of Diffusion

Schön, Jonas; Hamer, Phillip; Hammann, Benjamin; Zechner, Christoph; Kwapil, Wolfram; Schubert, Martin |

Zeitschriftenaufsatz

Journal Article

|

| 2025 |

The differential impact of light soaking and dark annealing on hydrogen species during a LeTID cycle in boron-doped FZ silicon: A quantitative FT-IR study

Aßmann, Nicole; Hammann, Benjamin; Frøland, Mariann Carlsen; Kwapil, Wolfram; Monakhov, Eduard |

Zeitschriftenaufsatz

Journal Article

|

| 2025 |

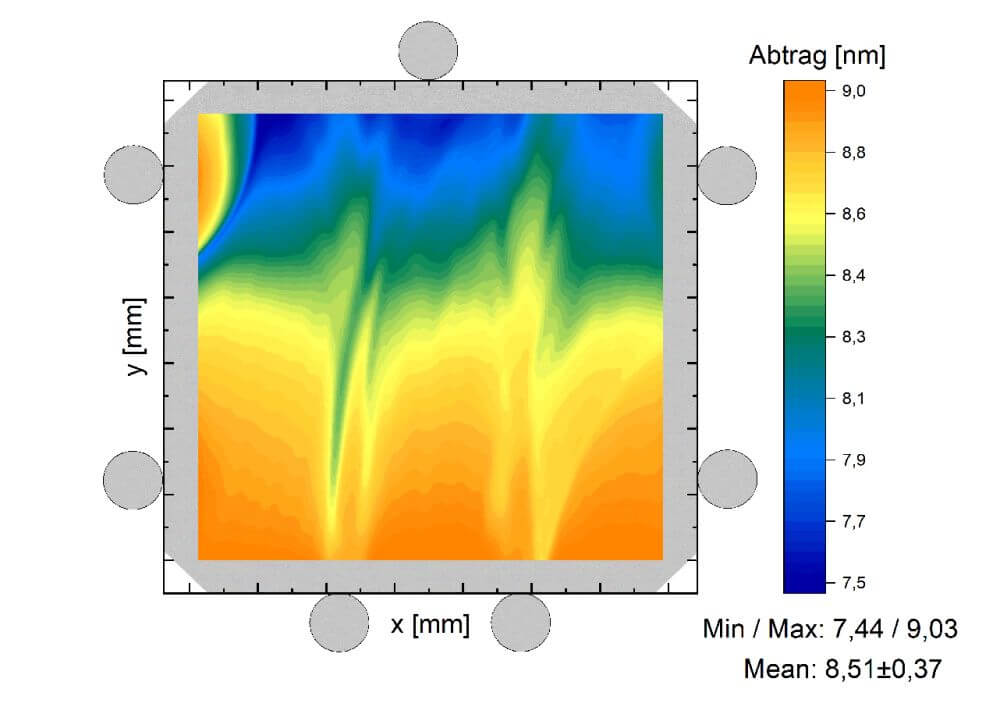

Physics-Informed Machine Learning for TCO-Layer Thickness Prediction and Process Analysis from Multi-Spectral Images

Wörnhör, Alexandra; Senthil Kumar, Saravana Kumar; Burkhardt, Daniel; Schönauer, Jonas Johannes Felix; Pingel, Sebastian; Voicu Vulcanean, Ioan; Steinmetz, Anamaria; Rein, Stefan; Demant, Matthias |

Zeitschriftenaufsatz

Journal Article

|

| 2025 |

Review on hydrogen in silicon solar cells: From its origin to its detrimental effects

Hammann, Benjamin; Schindler, Florian; Schön, Jonas; Kwapil, Wolfram; Schubert, Martin; Glunz, Stefan |

Zeitschriftenaufsatz

Journal Article

|

| 2025 |

Dynamic Tracking: A Machine Learning Approach for PV Yield Optimization

Burkhardt, Daniel; Bruno, Maddalena; Kurumundayil, Leslie Lydia; Berwind, Matthew; Demant, Matthias |

Zeitschriftenaufsatz

Journal Article

|

| 2025 |

Effective In-Situ TOPCon Gettering of Epitaxially Grown Silicon Wafers during Bottom Solar Cell Fabrication

Rittmann, Clara; Meßmer, Pascal; Schindler, Florian; Polzin, Jana-Isabelle; Richter, Armin; Weiss, Charlotte; Schubert, Martin; Janz, Stefan; Drießen, Marion |

Zeitschriftenaufsatz

Journal Article

|

| 2025 |

Fast Ground Irradiance Computations for Agrivoltaics via Physics-Informed Deep Learning Models

Kurumundayil, Leslie Lydia; Burkhardt, Daniel; Gfüllner, Leonhard Josef; Rupitsch, Stefan; Preu, Ralf; Berwind, Matthew; Demant, Matthias |

Zeitschriftenaufsatz

Journal Article

|

| 2025 |

Approaches for Reducing Metallization-Induced Losses in Industrial TOPCon Solar Cells

Mack, Sebastian; Ourinson, Daniel; Meßmer, Marius; Teßmann, Christopher; Krieg, Katrin; Benick, Jan; Huyeng, Jonas; Greulich, Johannes; Wolf, Andreas |

Zeitschriftenaufsatz

Journal Article

|

| 2025 |

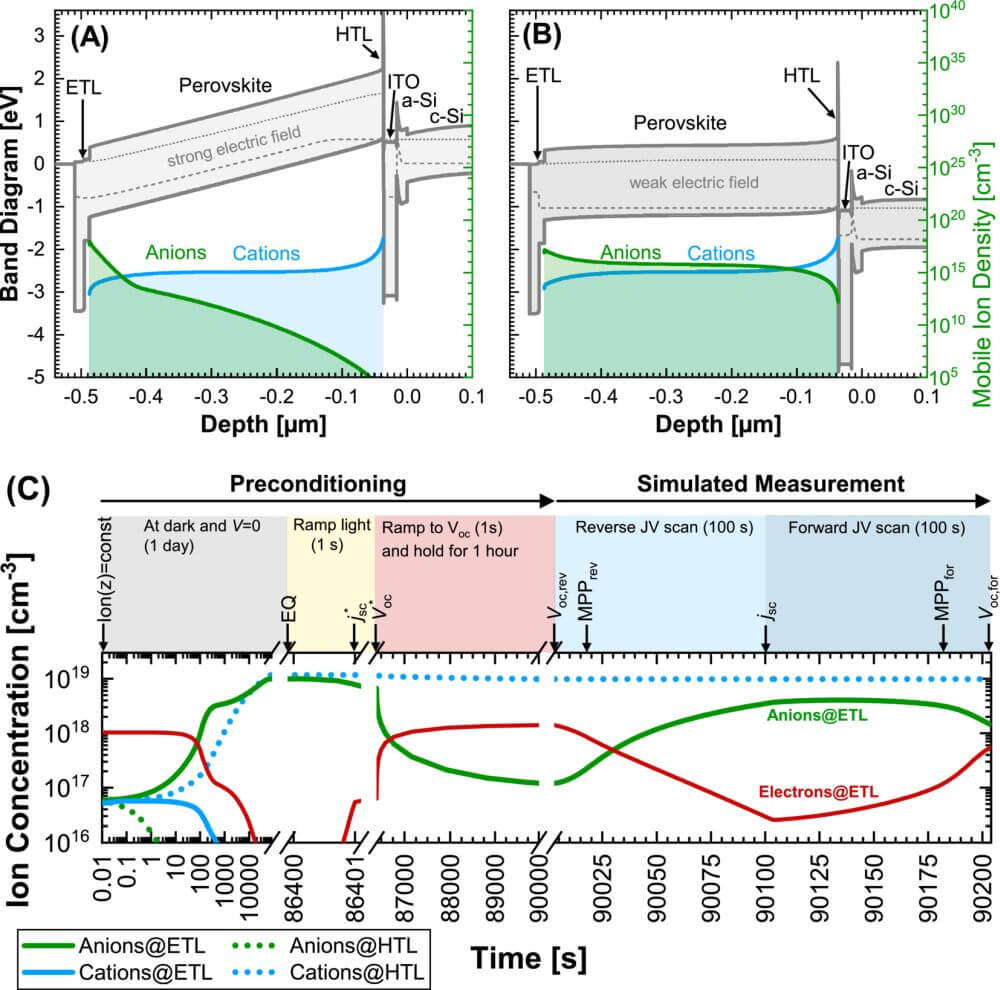

Towards More Reliable Measurement Procedures of Perovskite-Silicon Tandem Solar Cells: The Role of Transient Device Effects and Measurement Conditions

Meßmer, Christoph Alexander; Chojniak, David; Bett, Alexander J.; Reichmuth, Kasimir; Hohl-Ebinger, Jochen; Bivour, Martin; Hermle, Martin; Schön, Jonas; Schubert, Martin; Glunz, Stefan |

Zeitschriftenaufsatz

Journal Article

|

| 2025 |

Microstructure Analysis of Current-Fired Contacts on TOPCon Layers

Greulich, Johannes; Leon, Cyril; Mack, Sebastian; Ourinson, Daniel; Huyeng, Jonas; Rein, Stefan |

Zeitschriftenaufsatz

Journal Article

|

| 2025 |

PhocoHila - Photonische Prozesse zum schnellen, präzisen und flexiblen Heizen von Halbleiterbauelementen

Meyer, Fabian; Münzer, Anna; Folcarelli, Lukas; Roder, Sebastian; Schubert, Martin |

Bericht

Report

|

| 2025 |

Revealing Charge Carrier Transport and Selectivity Losses in Perovskite Silicon Tandem Solar Cells

Fischer, Oliver; Bett, Alexander J.; Zhu, Yan; Meßmer, Christoph Alexander; Bui, Anh Dinh; Schygulla, Patrick; Fell, Andreas; Er-Raji, Oussama; Kore, Bhushan; Schindler, Florian; Macdonald, Daniel; Hameiri, Ziv; Glunz, Stefan; Schubert, Martin |

Zeitschriftenaufsatz

Journal Article

|

| 2025 |

Fast Luminescence Imaging of Multijunction Solar Cells with a Single Shot

Greulich, Johannes; Fischer, Oliver; Rein, Stefan |

Zeitschriftenaufsatz

Journal Article

|

| 2025 |

Minimizing Open-Circuit Voltage Losses in Perovskite/Perovskite/Silicon Triple-Junction Solar Cell with Optimized Top Cell

Heydarian, Minasadat; Shaji, Athira; Fischer, Oliver; Günthel, Michael; Karalis, Orestis; Heydarian, Maryamsadat; Bett, Alexander J.; Hempel, Hannes; Bivour, Martin; Schindler, Florian; Schubert, Martin; Bett, Andreas W.; Glunz, Stefan; Borchert, Anna Juliane; Schulze, Patricia S.C. |

Zeitschriftenaufsatz

Journal Article

|

| 2025 |

Quality Activation Maps: Inline Efficiency Mapping of Solar Cells using Weakly-Supervised Regression

Kunze, Philipp; Kwapil, Wolfram; Rein, Stefan; Demant, Matthias |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

UV-Induced Degradation of Industrial PERC, TOPCon, and HJT Solar Cells: The Next Big Reliability Challenge?

Thome, Fabian; Meßmer, Pascal; Mack, Sebastian; Schnabel, Erdmut; Schindler, Florian; Kwapil, Wolfram; Schubert, Martin |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

Spectrometric Characterization for Triple-Junction Solar Cells

Aulich, Johanna; Chojniak, David; Bett, Alexander J.; Steiner, Marc; Schindler, Florian; Siefer, Gerald; Schubert, Martin; Goldschmidt, Jan Christoph; Glunz, Stefan |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

Loss Analysis of a Perovskite/Perovskite/Silicon Solar Cell

Restat, Luis; Meßmer, Christoph Alexander; Schön, Jonas; Heydarian, Maryamsadat; Heydarian, Minasadat; Schubert, Martin; Glunz, Stefan |

Poster

|

| 2024 |

Opto-electrical modelling of perovskite/perovskite/silicon triple-junction solar cells: Towards the practical efficiency potential

Restat, Luis; Meßmer, Christoph Alexander; Heydarian, Maryamsadat; Heydarian, Minasadat; Schön, Jonas; Schubert, Martin; Glunz, Stefan |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

Reducing Time and Costs of FT-IR Studies of the Effect of SiNx, Dopants, and Emitter on Hydrogen Species in Si Wafers and Solar Cell Structures

Aßmann, Nicole; Søndenå, Rune; Hammann, Benjamin; Kwapil, Wolfram; Monakhov, Eduard |

Konferenzbeitrag

Conference Paper

|

| 2024 |

Deciphering the Role of Hydrogen in the Degradation of Silicon Solar Cells under Light and elevated Temperature

Hammann, Benjamin; Aßmann, Nicole; Vieira Rodrigues, Pedro; Kwapil, Wolfram; Schindler, Florian; Schubert, Martin; Glunz, Stefan |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

Modelling the Metallization and Busbar Layout of Perovskite-Silicon Tandem Solar Cells to Account for Losses in Cell-to-Module Analyses

Reichel, Christian; Huyeng, Jonas; Greulich, Johannes; Neuhaus, Holger |

Konferenzbeitrag

Conference Paper

|

| 2024 |

Why is Gallium-Doped Silicon (Sometimes) Stable? Kinetics of Light and Elevated Temperature Induced Degradation

Thome, Fabian; Yilmaz, Cem; Kwapil, Wolfram; Schindler, Florian; Schubert, Martin |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

Stability of industrial gallium-doped Czochralski silicon PERC cells and wafers

Niewelt, Tim; Maischner, Felix; Kwapil, Wolfram; Khorani, Edris; Pain, Sophie L.; Jung, Yujin; Hopkins, Eduard C. B.; Frosch, Manfred; Altermatt, Pietro P.; Guo, Harry; Wang, Yuchin; Grant, Nicholas E.; Murphy, John D. |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

The Impact of Measurement Conditions on Solar Cell Efficiency

Rauer, Michael; Fell, Andreas; Wöhler, Wilkin; Hinken, David; Reichel, Christian; Bothe, Karsten; Schubert, Martin; Hohl-Ebinger, Jochen |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

Light Trapping in Silicon Solar Cells Including Secondary Reflection on the Surrounding

Wöhler, Wilkin; Greulich, Johannes |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

Recent Progress in Monolithic Two-Terminal Perovskite-Based Triple-Junction Solar Cells

Heydarian, Minasadat; Heydarian, Maryamsadat; Schygulla, Patrick; Reichmuth, Kasimir; Bett, Alexander J.; Hohl-Ebinger, Jochen; Schindler, Florian; Hermle, Martin; Schubert, Martin; Schulze, Patricia; Borchert, Anna Juliane; Glunz, Stefan |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

Quick Spectrometric Characterization of Monolithic Perovskite Silicon Tandem Solar Cells Using Monochromatic Light Sources

Fischer, Oliver; Bett, Alexander J.; Abrorov, Khusan; Mahmoud, Mohamed Abdelaziz Abdelnaby; Schindler, Florian; Glunz, Stefan W.; Schubert, Martin C. |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

Understanding and Minimizing Perimeter Losses of Silicon-Based Monolithic Tandem Solar Cells - a Simulation Study

Fell, Andreas; Bivour, Martin; Hanser, Mario; Schubert, Martin |

Konferenzbeitrag

Conference Paper

|

| 2024 |

Deep-Learning Based Depth-Tracking of Stacking-Faults in Epitaxially Grown Silicon Wafers

Trötschler, Theresa; Al-Hajjawi, Saed; Raghavendran, Siddharth; Haunschild, Jonas; Demant, Matthias; Haunschild, Jonas; Wörnhör, Alexandra; Rein, Stefan; Demant, Matthias; Rein, Stefan |

Konferenzbeitrag

Conference Paper

|

| 2024 |

Understanding Ion-Related Performance Losses in Perovskite-Based Solar Cells by Capacitance Measurements and Simulation

Meßmer, Christoph Alexander; Parion, Jonathan; Meza, Cristian V.; Ramesh, Santhosh; Bivour, Martin; Heydarian, Minasadat; Schön, Jonas; Radhakrishnan, Hariharsudan S.; Schubert, Martin; Glunz, Stefan |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

Integrated Inline Characterisation Techniques for Improved Silicon Heterojunction Solar Cell Production

Diestel, Christian; Senthil Kumar, Saravana Kumar; Wörnhör, Alexandra; Burkhardt, Daniel; Wöhrle, Nico; Pingel, Sebastian; Demant, Matthias; Haunschild, Jonas; Rein, Stefan |

Konferenzbeitrag

Conference Paper

|

| 2024 |

Recombination Activity of Crystal Defects in Epitaxially Grown Silicon Wafers for Highly Efficient Solar Cells

Rittmann, Clara; Supik, Ella Susann; Drießen, Marion; Heinz, Friedemann D.; Botchak Mouafi, Yves Patrick; Schindler, Florian; Weiss, Charlotte; Schubert, Martin; Janz, Stefan |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

Approaches for Reducing Metallization-Induced Losses and Cost in Industrial TOPCon Solar Cells

Mack, Sebastian; Ourinson, Daniel; Krieg, Katrin; Teßmann, Christopher; Meßmer, Marius; Haberstroh, René; Kluska, Sven; Greulich, Johannes; Huyeng, Jonas; Wolf, Andreas; Clement, Florian |

Konferenzbeitrag

Conference Paper

|

| 2024 |

Solar degradation and stability of lead-free light absorber Cs2AgBiBr6 in ambient conditions

Jöckel, Dennis Michael; Yoon, Song Hak; Frebel, Alexander; Meles Neguse, Samuel; Rossa, Jürgen Dieter; Bett, Alexander J.; Schubert, Martin; Wiedenmeyer, Marc; Balke-Grünewald, Benjamin; Weidenkaff, Anke |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

Review and Highlights of More than 30 Years Research on Ever Improving Technology for PERC Solar Cells at Fraunhofer ISE

Lohmüller, Elmar; Lohmüller, Sabrina; Saint-Cast, Pierre; Greulich, Johannes; Glunz, Stefan; Preu, Ralf |

Konferenzbeitrag

Conference Paper

|

| 2024 |

Integrated Inline Characterisation Techniques for Improved Silicon Heterojunction Solar Cell Production

Diestel, Christian; Senthil Kumar, Saravana Kumar; Wörnhör, Alexandra; Burkhardt, Daniel; Wöhrle, Nico; Haunschild, Jonas; Demant, Matthias; Pingel, Sebastian; Rein, Stefan |

Vortrag

Presentation

|

| 2024 |

Toward Highly Efficient Low-Carbon Footprint Solar Cells: Impact of High-Temperature Processing on Epitaxially Grown p-Type Silicon Wafers

Rittmann, Clara; Meßmer, Pascal; Niewelt, Tim; Supik, Ella Susann; Heinz, Friedemann; Richter, Armin; Botchak Mouafi, Yves P.; Sanz, Sarah; Terheiden, Barbara; Weiss, Charlotte; Drießen, Marion; Schindler, Florian; Janz, Stefan; Schubert, Martin |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

Impact of perovskite subcell breakdown on the performance of perovskite/perovskite/silicon triple-junction solar cells

Heydarian, Maryamsadat; Bett, Alexander J.; Meßmer, Christoph Alexander; Aulich, Johanna; Fischer, Oliver; Heydarian, Minasadat; Gupta, Yashika; Schulze, Patricia; Borchert, Anna Juliane; Schindler, Florian; Schubert, Martin; Glunz, Stefan |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

TOPCon R&D Status and Developments Update

Wolf, Andreas; Mack, Sebastian; Richter, Armin; Krieg, Katrin; Lohmüller, Elmar; Polzin, Jana-Isabelle; Schube, Jörg; Thome, Fabian; Hammann, Benjamin; Hanser, Mario; Nagel, Henning; Horzel, Jörg; Schygulla, Patrick; Huyeng, Jonas; Kluska, Sven; Benick, Jan; Hofmann, Marc; Greulich, Johannes; Rentsch, Jochen; Clement, Florian; Glunz, Stefan; Preu, Ralf |

Vortrag

Presentation

|

| 2024 |

Review and Highlights of More than 30 Years Research on Ever Improving Technology for PERC Solar Cells at Fraunhofer ISE

Lohmüller, Elmar; Lohmüller, Sabrina; Saint-Cast, Pierre; Greulich, Johannes; Glunz, Stefan; Preu, Ralf |

Poster

|

| 2024 |

Digitale Bestandsaufnahme für die Wärmewende mit Deep Learning

Hain, Antonia; Gölzhäuser, Simon; Meyer, Robert; Ihlenburg, Moritz; Herkel, Sebastian; Réhault, Nicolas; Demant, Matthias |

Konferenzbeitrag

Conference Paper

|

| 2024 |

Doping dependence of boron-hydrogen dynamics in crystalline silicon

Vieira Rodrigues, Pedro; Hammann, Benjamin; Aßmann, Nicole; Schön, Jonas; Kwapil, Wolfram; Niewelt, Tim; Schindler, Florian; Monakhov, Eduard V.; Schubert, Martin |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

Understanding Ion-Related Performance Losses in Perovskite-Based Solar Cells by Capacitance-Voltage Measurements and Simulation

Meßmer, Christoph Alexander; Parion, Jonathan; Meza, Cristian V.; Ramesh, Santhosh; Bivour, Martin; Radhakrishnan, Hariharsudan S.; Schön, Jonas; Schubert, Martin; Glunz, Stefan; Heydarian, Maryamsadat |

Vortrag

Presentation

|

| 2023 |

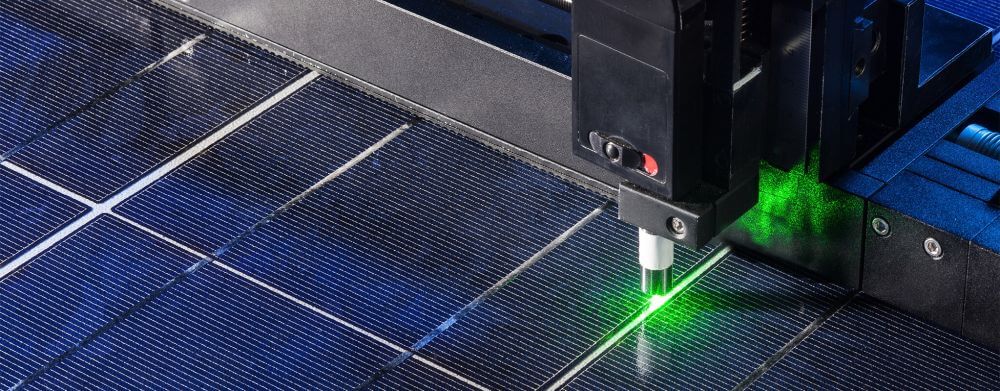

Understanding Current Paths and Temprature Distributions during 'Laser Enhanced Contact Optimization' (LECO)

Höffler, Hannes; Simon, Felix; Krassowski, Eve; Greulich, Johannes |

Konferenzbeitrag

Conference Paper

|

| 2023 |

Comparing MDP, QSSPC and PL Imaging for the Production Control of Heterojunction Solar Cells

Diestel, Christian; Senthil Kumar, Saravana Kumar; Schüler, Nadine; Leonhardt, Marcel; Haunschild, Jonas; Rein, Stefan |

Konferenzbeitrag

Conference Paper

|

| 2023 |

Monitoring of porous silicon layers for epitaxial wafer production using inline reflectance spectroscopy

Vahlman, Henri; Al-Hajjawi, Saed; Haunschild, Jonas; Wöhrle, Nico; Richter, Maxi; Jablonka, Lukas; Schremmer, Hans; Rein, Stefan |

Konferenzbeitrag

Conference Paper

|

| 2023 |

IV Measurements of Shingle Solar Cells

Krieg, Alexander; Ramspeck, Klaus; Wöhrle, Nico; Kunze, Philipp; Rauer, Michael; Fell, Andreas; Greulich, Johannes; Rein, Stefan |

Konferenzbeitrag

Conference Paper

|

| 2023 |

IV Measurements of Shingle Solar Cells

Krieg, Alexander; Ramspeck, Klaus; Wöhrle, Nico; Kunze, Philipp; Rauer, Michael; Fell, Andreas; Greulich, Johannes; Rein, Stefan |

Poster

|

| 2023 |

Measurement of Local Recombination Activity in High Diffusion Length Semiconductors

Heinz, Friedemann; Oezkent, Maximilian; Rittmann, Clara; Schindler, Florian; Schubert, Martin; Kwapil, Wolfram; Glunz, Stefan |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Characterization of thin-film structures of silicon heterojunction solar cells with inline reflectance spectroscopy

Senthil Kumar, Saravana Kumar; Vahlman, Henri; Pingel, Sebastian; Voicu Vulcanean, Ioan; Steinmetz, Anamaria; Haunschild, Jonas; Rupitsch, Stefan; Rein, Stefan |

Konferenzbeitrag

Conference Paper

|

| 2023 |

On the Conversion Between Recombination Rates and Electronic Defect Parameters in Semiconductors

Juhl, Mattias K.; Heinz, Friedemann; Coletti, Gianluca; Rougieux, Fiacre; Sun, Chang; Vacqueiro Contreras, Michelle; Niewelt, Tim; Krich, Jacob; Schubert, Martin |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

A Self-Consistent Hybrid Model Connects Empirical and Optical Models for Fast, Non-Destructive Inline Characterization of Thin, Porous Silicon Layers

Wörnhör, Alexandra; Vahlman, Henri; Demant, Matthias; Rein, Stefan |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

A Grain Orientation-Independent Single-Step Saw Damage Gettering/Wet texturing Process for Efficient Silicon Solar Cells

Jung, Yujin; Min, Kwan Hong; Post, Regina; Kwapil, Wolfram; Schubert, Martin; Kim, Donghwan; Kang, Yoonmook; Lee, Hae-Sok |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Understanding Contact Nonuniformities at Interfaces in Perovskite Silicon Tandem Solar Cells Using Luminescence Imaging, Lock-In Thermography, and 2D/3D Simulations

Fischer, Oliver; Fell, Andreas; Meßmer, Christoph Alexander; Efinger, Raphael; Schindler, Florian; Glunz, Stefan; Schubert, Martin |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Inline Characterization of Ultrathin Amorphous Silicon Stacks in Silicon Heterojunction Solar Cell Precursors with Differential Reflectance Spectroscopy

Senthil Kumar, Saravana Kumar; Vahlman, Henri; Al-Hajjawi, Saed; Diestel, Christian; Haunschild, Jonas; Rupitsch, Stefan; Rein, Stefan |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Spectrometric Characterization of Monolithic Perovskite/Silicon Tandem Solar Cells

Bett, Alexander J.; Chojniak, David; Schachtner, Michael; Reichmuth, Kasimir; Kabakli, Özde Seyma; Schulze, Patricia; Fischer, Oliver; Schindler, Florian; Hohl-Ebinger, Jochen; Siefer, Gerald; Schubert, Martin |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Highly Efficient Low Carbon Footprint Solar Cells: Impact of High Temperature Processing on Epitaxially Grown P-Type Silicon Wafers

Rittmann, Clara; Meßmer, Pascal; Supik, Ella Susann; Heinz, Friedemann D.; Botchak Mouafi, Yves Patrick; Drießen, Marion; Weiss, Charlotte; Schindler, Florian |

Poster

|

| 2023 |

Next Generation High Throughput Production Processes & Inline Characterization for Si Solar Cells

Clement, Florian; Meßmer, Marius; Höffler, Hannes; Ourinson, Daniel; Goraya, Baljeet Singh; Emanuel, Gernot; Meyer, Fabian; Lorenz, Andreas; Bartsch, Jonas; Demant, Matthias; Nold, Sebastian; Wolf, Andreas; Zimmer, Martin; Greulich, Johannes; Preu, Ralf; Köpge, Ringo; Ramspeck, Klaus; Hemsendorf, Marc; Straub, Benedikt; Ebert , Christian; Drews, Matthias; Jooss, Wolfgang; Schmid, Elina; Schönfelder, Stephan |

Vortrag

Presentation

|

| 2023 |

Every Cell Needs a Beautiful Image: On-The-Fly Contacting Measurements for High-Throughput Production

Kurumundayil, Leslie Lydia; Ramspeck, Klaus; Rein, Stefan; Demant, Matthias |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Understanding the Impact of the Cooling Ramp of the Fast-Firing Process on Light- and Elevated-Temperature-Induced Degradation

Hammann, Benjamin; Aßmann, Nicole; Schön, Jonas; Kwapil, Wolfram; Schindler, Florian; Roder, Sebastian; Monakhov, Eduard V.; Schubert, Martin |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Process influences on LeTID in Ga-doped silicon

Maischner, Felix; Kwapil, Wolfram; Greulich, Johannes; Jung, Yujin; Höffler, Hannes; Saint-Cast, Pierre; Schubert, Martin; Rein, Stefan; Glunz, Stefan |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Si-Epitaxy with Mixtures of Trichlorosilane and Silicon Tetrachloride Precursors at Different Temperatures

Drießen, Marion; Meyer, Tom; Ohnemus, Markus; Messmer, Pascal; Sorgenfrei, Ralf; Schindler, Florian; Weiss, Charlotte; Janz, Stefan |

Vortrag

Presentation

|

| 2023 |

The Impact of Different Hydrogen Configurations on Light- and Elevated-Temperature-Induced Degradation

Hammann, Benjamin; Assmann, Nicole; Weiser, Philip M.; Kwapil, Wolfram; Niewelt, Tim; Schindler, Florian; Søndenå, Rune; Monakhov, Eduard V.; Schubert, Martin |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

LeTID Stability Tests on Gallium-Doped Industrial PERC Cells and Wafers

Niewelt, Tim; Maischner, Felix; Khorani, Edris; Pain, Sophie; Grant, Nicholas E.; Kwapil, Wolfram; Altermatt, Pietro P.; Murphy, John D. |

Vortrag

Presentation

|

| 2023 |

Spectrometric Determination of Current Matching in Perovskite/Silicon Tandem Solar Cells

Bett, Alexander J.; Chojniak, David; Schachtner, Michael; Reichmuth, Kasimir; Schulze, Patricia; Kabakli, Özde Seyma; Heydarian, Minasadat; King, Hunter; Sittinger, Volker; Schindler, Florian; Goldschmidt, Jan Christoph; Hohl-Ebinger, Jochen; Siefer, Gerald; Bett, Andreas W.; Schubert, Martin |

Konferenzbeitrag

Conference Paper

|

| 2023 |

Epitaxially Grown p-type Silicon Wafers Ready for Cell Efficiencies Exceeding 25%

Rittmann, Clara; Schindler, Florian; Richter, Armin; Niewelt, Tim; Stolzenburg, Hannah; Steinhauser, Bernd; Dalke, Jonas; Drießen, Marion; Weiss, Charlotte; Janz, Stefan; Schubert, Martin |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

On the Robustness of the Determination of Metal-Induced Recombination from Photoluminescence Images on Solar Cells

Leon, Cyril; Saint-Cast, Pierre; Fell, Andreas; Greulich, Johannes; Rein, Stefan |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Loss Analysis of Fully-Textured Perovskite Silicon Tandem Solar Cells: Characterization Methods and Simulation toward the Practical Efficiency Potential

Er-Raji, Oussama; Meßmer, Christoph Alexander; Bett, Alexander J.; Fischer, Oliver; Reichmuth, Kasimir; Schindler, Florian; Bivour, Martin; Schultz-Wittmann, Oliver; Borchert, Anna Juliane; Hermle, Martin; Schön, Jonas; Heinz, Friedemann D.; Schubert, Martin; Schulze, Patricia; Glunz, Stefan |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Spatially Resolved and Subcell-Selective Implied Open-Circuit Voltage Measurements on Perovskite Silicon Tandem Solar Cells

Fischer, Oliver; Bui, Anh Dinh; Schindler, Florian; Macdonald, Daniel; Glunz, Stefan; Nguyen, Hieu T.; Schubert, Martin |

Vortrag

Presentation

|

| 2023 |

Comparing MDP, QSSPC and PL Imaging for the Production Control of Heterojunction Solar Cells

Diestel, Christian; Senthil Kumar, Saravana Kumar; Schüler, Nadine; Leonhardt, Marcel; Haunschild, Jonas; Rein, Stefan |

Poster

|

| 2023 |

LeTID in PERC Cells from Gallium-Doped Czochralski Silicon: Extent, Accelerated Testing and Mitigation via an Adapted Firing Process

Maischner, Felix; Greulich, Johannes; Kwapil, Wolfram; Ourinson, Daniel; Glunz, Stefan; Rein, Stefan |

Vortrag

Presentation

|

| 2023 |

LeTID Mitigation via an Adapted Firing Process in p-Type PERC Cells from Gallium-doped Czochralski Silicon

Maischner, Felix; Greulich, Johannes; Kwapil, Wolfram; Ourinson, Daniel; Glunz, Stefan; Rein, Stefan |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Hydrogen Reactions in c-Si:B During Illumination at Room Temperature

Kwapil, Wolfram; Hammann, Benjamin |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

High Lifetime Ga-doped Cz-Si for Carrier-Selective Junction Solar Cells

Horzel, Jörg; Mack, Sebastian; Voicu Vulcanean, Ioan; Zimmermann, Karin; Pingel, Sebastian; Kwapil, Wolfram; Maischner, Felix; Höffler, Hannes; Bashardoust, Sattar; Wagenmann, Dirk; Greulich, Johannes; Seif, Johannes; Steinmetz, Anamaria; Rentsch, Jochen |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Contactless Inline IV Measurement of Solar Cells Using an Empirical Model

Kunze, Philipp; Greulich, Johannes; Tummalieh, Ammar; Wirtz, Wiebke; Höffler, Hannes; Wöhrle, Nico; Glunz, Stefan; Rein, Stefan; Demant, Matthias |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Maximizing Current Density in Monolithic Perovskite Silicon Tandem Solar Cells

Heydarian, Minasadat; Meßmer, Christoph Alexander; Bett, Alexander J.; Heydarian, Maryamsadat; Chojniak, David; Kabakli, Özde Seyma; Tutsch, Leonard; Bivour, Martin; Siefer, Gerald; Schubert, Martin; Goldschmidt, Jan Christoph; Hermle, Martin; Glunz, Stefan; Schulze, Patricia |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Overview of key results achieved in H2020 HighLite project helping to raise the EU PV industries' competitiveness

Tous, Loïc; Govaert, Jonathan; Harrison, Samuel; Carrière, Carolyn; Barth, Vincent; Giglia, Valentin; Buchholz, Florian; Chen, Ning; Halm, Andreas; Faes, Antonin; Nogay, Gizem; Quest, Hugo; Rößler, Torsten; Fellmeth, Tobias; Reinwand, Dirk; Stolzenburg, Hannah; Schindler, Florian; Mittag, Max; Morlier, Arnaud; Bokalič, Matevž; Brecl, Kristijan; Kikelj, Miha; Topic, Marko; Kester, Josco C.P.; Wendlandt, Stefan; Galiazzo, Marco; Voltan, Alessandro; Galbiati, Giuseppe; Ortiga, Marc Estruga; Torregrosa, Frank; Grimm, Michael; Denafas, Julius; Radavičius, Tadas; Lukinskas, Povilas; Savisalo, Tuukka; Regrettier, Thomas; Gordon, Ivan |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Next Generation High-Throughput Cell Production Technologies: Impact on Equipment CAPEX, Footprint, and Labour Requirements

Goraya, Baljeet Singh; Georgiou-Sarlikiotis, Vasileios; Meßmer, Marius; Wolf, Andreas; Zimmer, Martin; Klawitter, Markus; Lorenz, Andreas; Ourinson, Daniel; Schneider, Jale; Greulich, Johannes; Emanuel, Gernot; Clement, Florian; Nold, Sebastian |

Vortrag

Presentation

|

| 2023 |

Quantifying Surface Recombination - Improvements in Determination and Simulation of the Surface Recombination Parameter J0s

Hammann, Benjamin; Steinhauser, Bernd; Fell, Andreas; Post, Regina; Niewelt, Tim; Kwapil, Wolfram; Wolf, Andreas; Richter, Armin; Höffler, Hannes; Schubert, Martin |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Monolithic Two-Terminal Perovskite/Perovskite/Silicon Triple-Junction Solar Cells with Open Circuit Voltage > 2.8 V

Heydarian, Maryamsadat; Heydarian, Minasadat; Bett, Alexander J.; Bivour, Martin; Schindler, Florian; Hermle, Martin; Schubert, Martin; Schulze, Patricia; Borchert, Anna Juliane; Glunz, Stefan |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Spatially Resolved Power Conversion Efficiency for Perovskite Solar Cells via Bias-Dependent Photoluminescence Imaging

Bui, Anh Dinh; Nguyen, Dang-Thuan; Fell, Andreas; Mozaffari, Naeimeh; Ahmad, Viqar; Duong, The; Li, Li; Truong, Thien N.; Wibowo, Ary Anggara; Nguyen, Nhat Dang Khoa; Fischer, Oliver; Schindler, Florian; Schubert, Martin; Weber, Klaus J.; White, Thomas P.; Catchpole, Kylie R.; Catchpole, Kylie R.; Macdonald, Daniel; Nguyen, Hieu T. |

Zeitschriftenaufsatz

Journal Article

|

| 2022 |

Verfahren und Vorrichtung zur Qualitätsbewertung einer Solarzelle

Greulich, Johannes; Höffler, Hannes; Wöhrle, Nico; Demant, Matthias |

Patent

|

| 2022 |

High Lifetime Ga-Doped Cz-Si for Carrier Selective Junction Solar Cells

Horzel, Jörg; Mack, Sebastian; Voicu Vulcanean, Ioan; Zimmermann, Karin; Pingel, Sebastian; Kwapil, Wolfram; Maischner, Felix; Höffler, Hannes; Bashardoust, Sattar; Wagenmann, Dirk; Greulich, Johannes; Seif, Johannes; Steinmetz, Anamaria; Rentsch, Jochen |

Konferenzbeitrag

Conference Paper

|

| 2022 |

LeTID mitigation via an adapted firing process in p-type PERC cells from SMART cast-monocrystalline, Czochralski and high-performance multicrystalline silicon

Maischner, Felix; Maus, Stephan; Greulich, Johannes M.; Lohmüller, Sabrina; Lohmüller, Elmar; Saint-Cast, Pierre; Ourinson, Daniel; Vahlman, Henri; Hergert, K.; Riepe, Stephan; Glunz, Stefan W.; Rein, Stefan |

Zeitschriftenaufsatz

Journal Article

|

| 2022 |

Combining drift-diffusion and equivalent-circuit models for efficient 3D tandem solar cell simulations

Fell, Andreas; Schultz-Wittmann, Oliver; Meßmer, Christoph Alexander; Schubert, Martin; Glunz, Stefan |

Zeitschriftenaufsatz

Journal Article

|

| 2022 |

Lessons learned from 25 years production technology research & development

Preu, Ralf; Rentsch, Jochen; Rein, Stefan; Clement, Florian; Nekarda, Jan; Saint-Cast, Pierre; Lohmüller, Sabrina; Lohmüller, Elmar; Greulich, Johannes; Wöhrle, Nico; Mack, Sebastian; Wolf, Andreas; Pingel, Sebastian; Steinmetz, Anamaria; Baliozian, Puzant; Goraya, Baljeet Singh; Nold, Sebastian; Glunz, Stefan; Bett, Andreas W. |

Vortrag

Presentation

|

| 2022 |

Epitaxially grown p-type silicon wafers ready for cell efficiencies exceeding 25 %

Rittmann, Clara; Dalke, Jonas; Richter, Armin; Steinhauser, Bernd; Drießen, Marion; Weiss, Charlotte; Schindler, Florian; Schubert, Martin; Janz, Stefan; Niewelt, Tim; Stolzenburg, Hannah |

Vortrag

Presentation

|

| 2022 |

Monolithic 2-Terminal Perovskite Silicon Tandem Solar Cells

Schulze, Patricia; Kabakli, Özde Seyma; Meßmer, Christoph Alexander; Heydarian, Minasadat; Er-Raji, Oussama; Heydarian, Maryamsadat; Efinger, Raphael; Schultz-Wittmann, Oliver; Fischer, Oliver; Bett, Alexander J.; Tutsch, Leonard; Pingel, Sebastian; Schubert, Martin; Hatt, Thibaud; Erath, Denis; Bivour, Martin; Goldschmidt, Jan Christoph; Glunz, Stefan; Hermle, Martin |

Vortrag

Presentation

|

| 2022 |

Monitoring of Porous Silicon Layers Used for Epitaxial Wafer Production with Inline Reflectance Spectroscopy

Vahlman, Henri Johannes; Al-Hajjawi, Saed; Haunschild, Jonas; Wöhrle, Nico; Richter, Maxi; Jablonka, Lukas; Schremmer, Hans; Rein, Stefan |

Zeitschriftenaufsatz

Journal Article

|

| 2022 |

21.4% Efficient SMART mono-Si PERC Solar Cells with Adapted Firing Process for LeTID Mitigation

Maischner, Felix; Maus, Stephan; Greulich, Johannes; Lohmüller, Sabrina; Lohmüller, Elmar; Saint-Cast, Pierre; Ourinson, Daniel; Hergert, Karin; Riepe, Stephan; Glunz, Stefan; Rein, Stefan |

Konferenzbeitrag

Conference Paper

|

| 2022 |

Laser-enhanced Contact Optimization on iTOPCon Solar Cells

Fellmeth, Tobias; Höffler, Hannes; Mack, Sebastian; Krassowski, Eve; Krieg, Katrin; Kafle, Bishal; Greulich, Johannes |

Zeitschriftenaufsatz

Journal Article

|