News #17

Fraunhofer ISE Successfully Produces TOPCon Solar Cell with 24 Percent Efficiency in M10 Format

The Fraunhofer Institute for Solar Energy Systems ISE is the first European research institute to switch to large-area M10 silicon wafers. A TOPCon solar cell immediately achieved a very good efficiency of 24.0 percent. This result was presented for the first time at the 20th Photovoltaic Technology Advisory Board Meeting of Fraunhofer ISE.

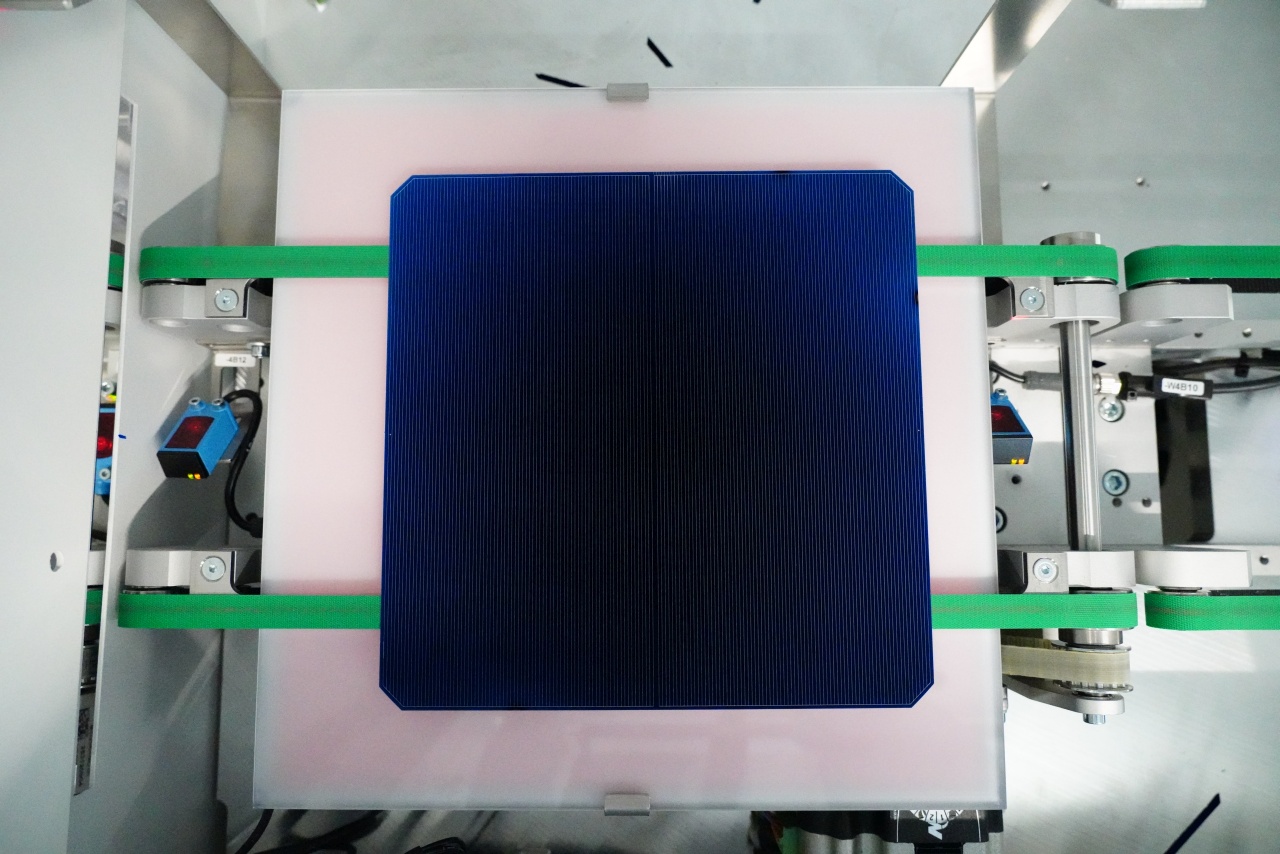

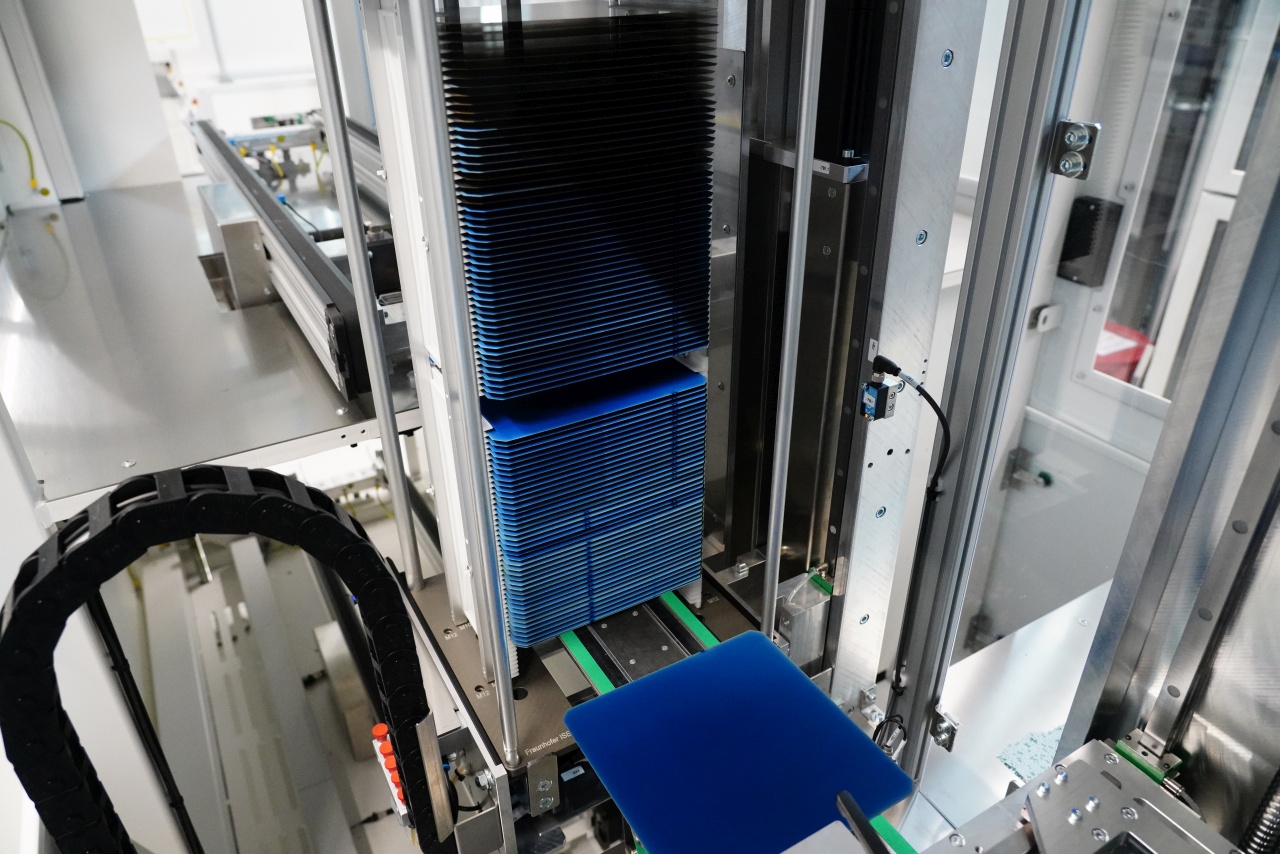

The trend in the photovoltaic industry is towards ever larger solar cells: While wafers with an edge length of 156.75 millimeters accounted for 80 percent of the market in 2018, wafers with an edge length of 182 millimeters dominate the market today. Quadratic wafers of this size bear the trade name “M10”. Solar modules with a large cell format are not only superior in terms of manufacturing costs, but also in terms of performance and efficiency. Large photovoltaic companies have therefore focused their investments on large-area wafers.

Now Fraunhofer ISE has successfully transitioned to the new format with the successful production of the large-format TOPCon solar cell (Tunnel Oxide Passivated Contact) within its PV Technology Evaluation Center (PV-TEC). "We are very excited that we can now support our industrial partners in optimizing their production processes with this large-area wafer format or even in newly entering into the production of such solar cells," says Sabrina Lohmüller. The physicist is deputy head of the Silicon and Perovskite-Silicon Tandem Solar Cells department and is also responsible for quality management at PV-TEC.

The highly efficient TOPCon cell architecture was originally developed at Fraunhofer ISE and was presented in 2013 for the first time demonstrating its record efficiency. In the last two years, production capacity of this cell type has been massively expanded worldwide. According to the International Roadmap Photovoltaics published by the VDMA, TOPCon solar cells will have a market share of almost 50 percent by 2024.

The large-format TOPCon solar cell, which was presented to industry representatives and funding bodies for the first time at the Photovoltaic Technology Advisory Board meeting in Freiburg, was processed entirely at Fraunhofer ISE. The highly efficient, approximately 120 µm thin solar cell was metallized with screen-printed contact fingers and calibrated at the CalTeC at the Institute for Solar Energy Research in Hameln. Researchers at Fraunhofer ISE also electroplate M10 solar cells with copper for metallization.

"Achieving an efficiency of 24.0% with the first batch suggests that we will exceed 25% with the next optimization steps. This recent success lays the foundation for our medium-term goal of large-area silicon-based tandem solar cells with an efficiency potential of well over 30 percent," says Dr. Ralf Preu PD, director of the Photovoltaics Division at Fraunhofer ISE, looking ahead.

Last modified: