Lithium-ion batteries (LIB) are revolutionizing the energy landscape, powering everything from portable electronics to electric vehicles and renewable energy systems. With their high energy density, efficiency, and long cycle life, LIBs are essential for the transition to sustainable energy solutions. Ongoing advancements in materials and design are making these batteries more environmentally friendly and cost-effective, addressing the growing demand for reliable energy storage.

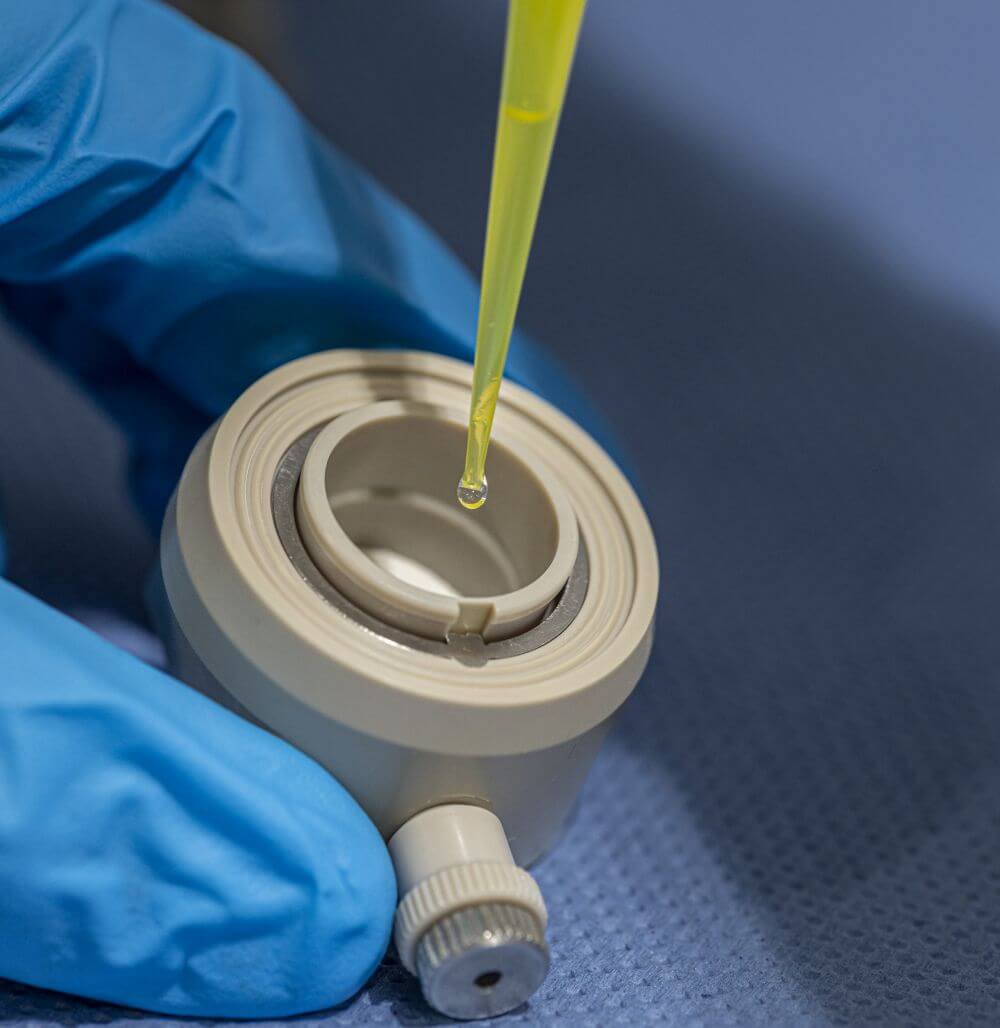

At Fraunhofer ISE, we focus on the entire lifecycle of lithium-ion batteries, beginning with the development of advanced battery active materials and extending to the recovery of battery materials through innovative recycling processes. The production and characterization of active materials, electrodes, and battery cells take place in our specialized laboratories, which include clean and dry rooms operating under various atmospheric conditions. We actively support research and development projects while collecting data for techno-economic analyses of lithium-ion technology. Our research enhances the performance and sustainability of lithium-ion batteries, ensuring they meet modern application demands while contributing to a more sustainable future. Through these efforts, we identify opportunities for improvement and innovation, advancing sustainable practices and overall battery technology efficiency.