Virtual Tour of our Fraunhofer ISE Center for High Efficiency Solar Cells

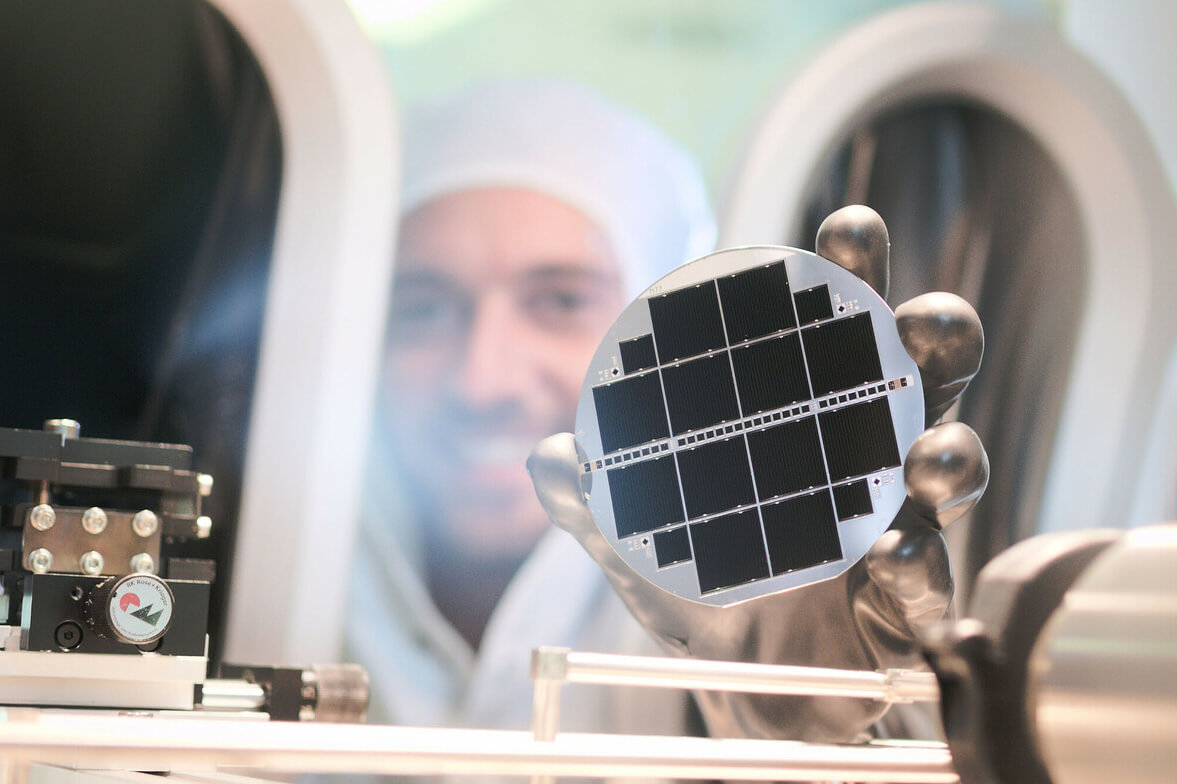

In the “Center for High Efficiency Solar Cells”, we evaluate technologies with which the highest PV efficiency values can be achieved, and we implement them at the uppermost international level. Applications for high efficiency solar cells include not only conventional solar modules but also power supplies for satellites, electric vehicles, autonomous sensors and electronic devices. Fraunhofer ISE holds several world records in the high efficiency solar cell sector, such as the record efficiency value for both-sides contacted silicon solar cells (26 %) and the top efficiency of 47.6 % for a four-junction solar cell based on a III-V multi-junction cell architecture.

To advance our position in photovoltaic cell research still further, we officially opened our new laboratory building in April 2021, after completing an intensive planning and building phase carried out over the past years. The new building contains cutting-edge cleanroom laboratories and equipment, which is suitable for addressing the future technological challenges. In the new Center for High Efficiency Solar Cells, advanced PV technology can be tested and optimized in state-of-the-art laboratories exceeding 1000 m2. In these facilities, research shall be conducted on innovative processes and technology for future application in industry. In addition to further development of silicon and III-V technology, one focus of the new center is on the combination of these two materials: High efficiency silicon-based tandem cells represent one of the most promising photovoltaic technologies. With the new laboratory building, Fraunhofer ISE aims to continue developing new, groundbreaking solar cell types and technologies in the future and thus increase the competitiveness of the German and European photovoltaic industry on the international level.

Flexibly usable clean-room laboratory (740 m² ) and further laboratories (340 m²) with customized ultra-pure media supply systemHigh-temperature diffusion (BBr3, POCl3)High-temperature oxidation (dry and moist)Ion implantation (P, B, H, Ga, Si)Wet-chemical processes for purification and structuring of Si or III-V wafersYellow-light zone for photolithography and laser lithography to create microstructures with bifacial alignmentWafer-bonding technology (for bonding III-V wafers or III-V and Si wafers)Plasma technology (PECVD and LPCVD deposition and plasma etching)Atomic layer deposition (ALD) for the deposition of Al2O3, TiOx, ITO, TCOs, etc.Processing of wafer dimensions up to M4 (162 x 162 mm2)Thermal and electron-beam evaporation of metals and dielectric layersGalvanic metallization for contacting solar cellsExtensive instrumentation for characterizing materials and components |