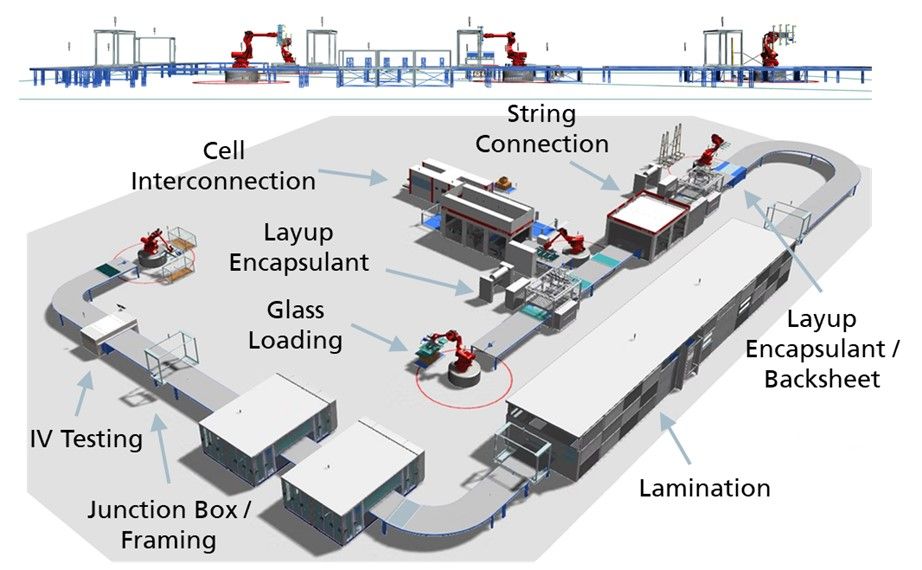

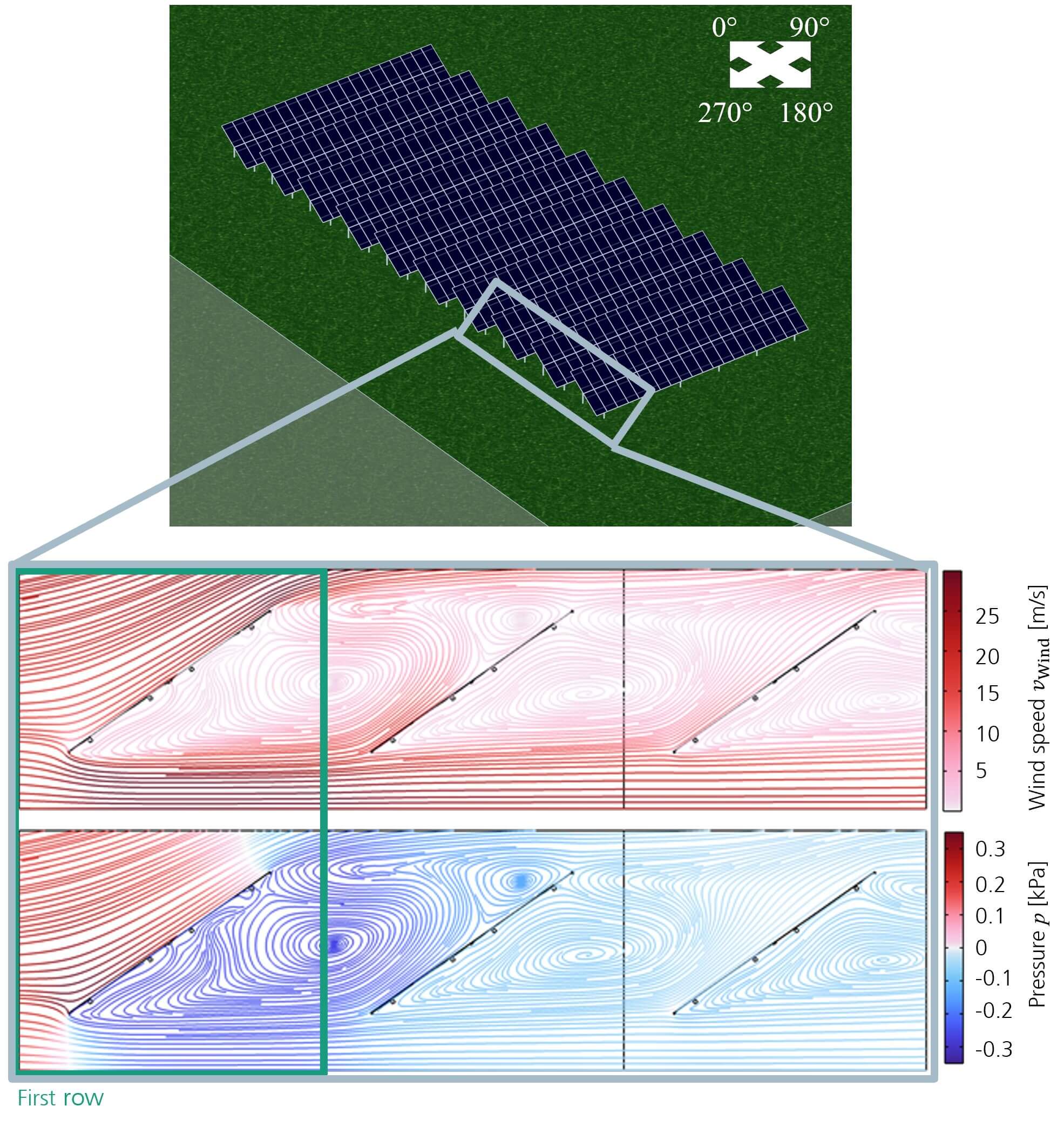

We start developing new PV module concepts and associated components on the computer, or more precisely on our high-performance computing cluster, even before the first prototype is built. In doing so, we draw on the wide range of possibilities in the field of digital product development and factory planning at Fraunhofer ISE.

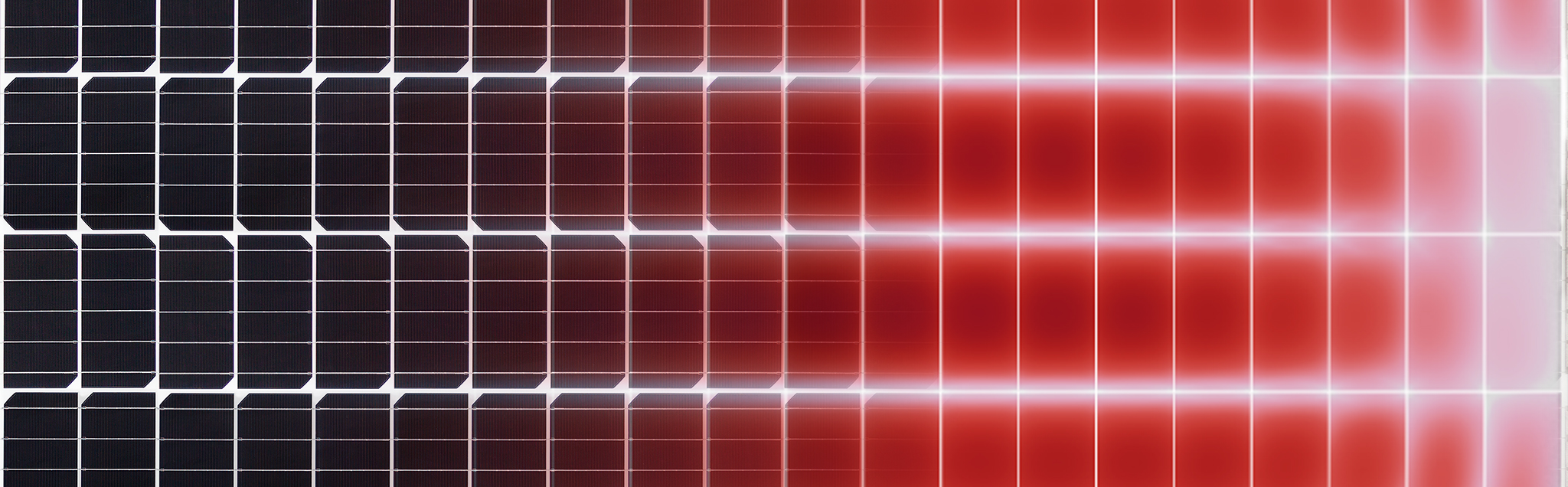

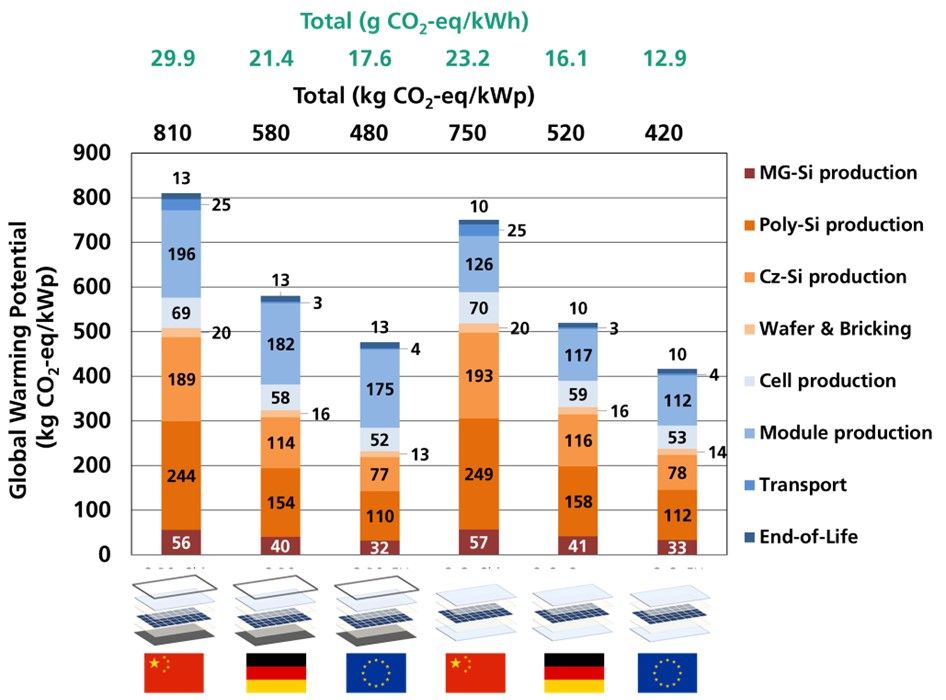

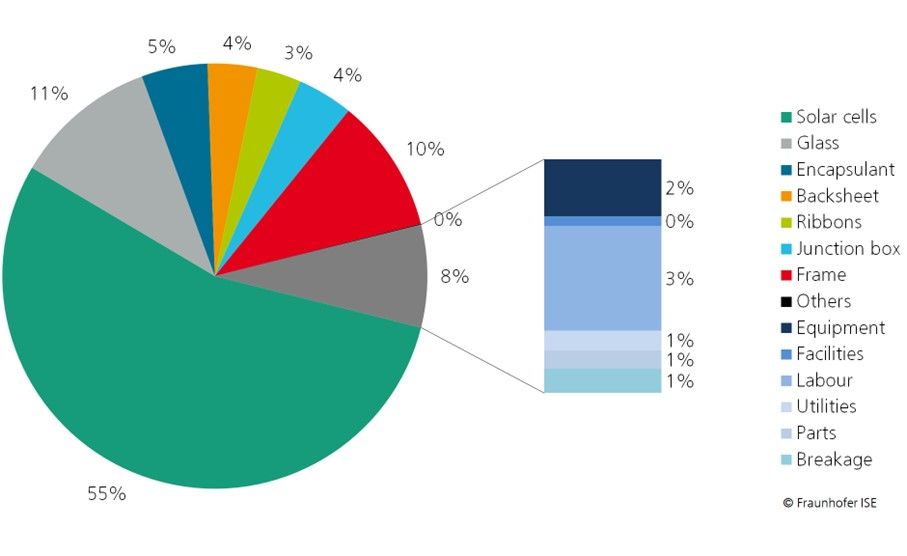

With the help of our simulations, we can precisely evaluate module concepts and materials even before the first prototype is produced. We consider aspects such as power and efficiency, mechanical stability, sustainability and module costs. Software-supported development thus saves time and costs and enables detailed analyses and holistic optimization. Our simulation tools are constantly validated and improved based on our experience at Module-TEC.

The factory simulations complement our cost accounting methods and thus contribute to the creation of an overall picture from which the total direct and indirect production costs of the module concepts can be derived.