The PV module production laboratory Module-TEC at Fraunhofer ISE offers a unique infrastructure and comprehensive possibilities for the development and testing of PV module technologies on over 1,000 m2. From the development and production of prototypes, which can be individually designed, through to small-scale industrial production.

In addition to production and process technology, extensive analysis facilities are available for quality control and for evaluating long-term stability. Our research focuses on connection technology and encapsulation for all industrially used solar cell technologies (e.g. TOPCon, HJT) and for future high-efficiency technologies (e.g. silicon perovskite tandem). We also develop application-specific modules for building and vehicle integration.

Our team of scientists and engineers will support you from virtual analysis and joint design development to the construction of prototypes and small series and the evaluation of long-term stability. Thanks to a large selection of connection technologies and module materials (solar cells, glass, encapsulation materials, backsheets, connectors, etc.), different structures can be realized in a short time.

Test your new product ideas with us!

Innovative connection technology

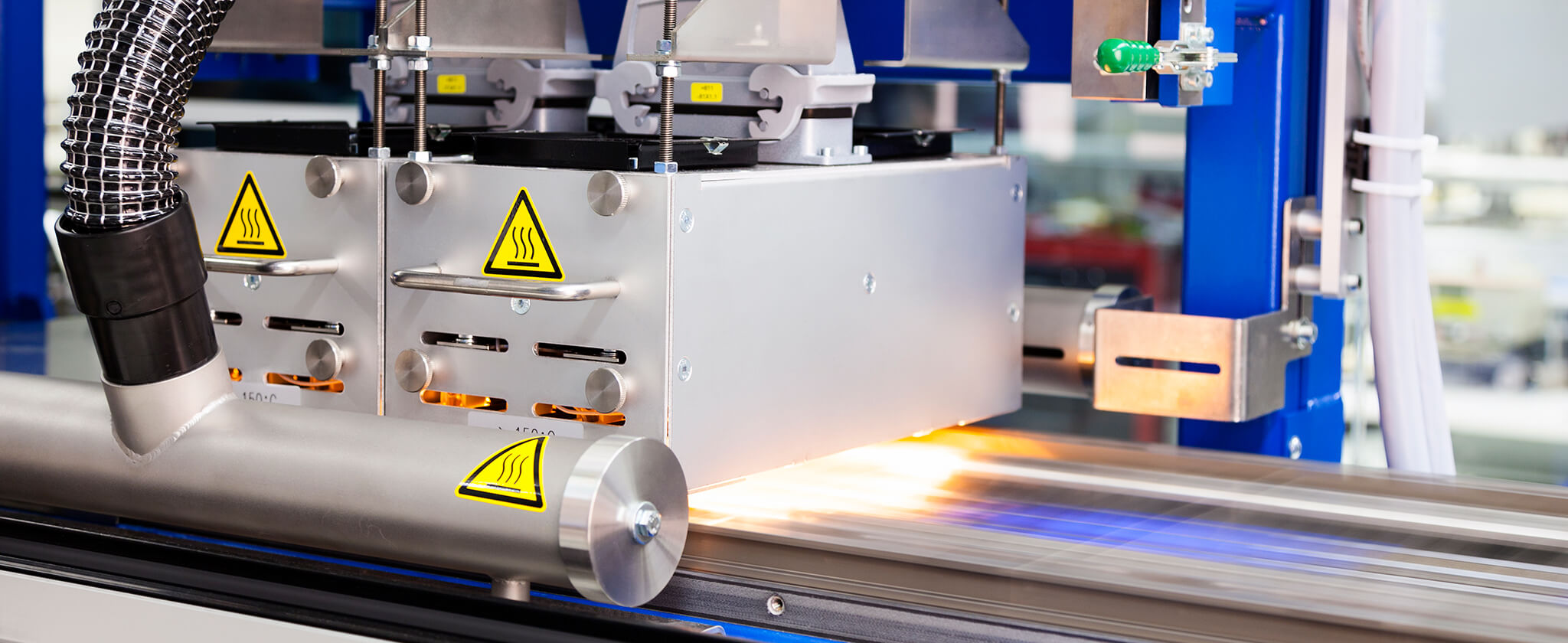

State-of-the-art industrial stringer systems with infrared soldering technology and conductive bonding are available for the series connection of solar cells. This enables us to implement the round wire interconnection widely used in the industry, interconnection with lead-free solders and low-temperature connection technology for HJT and tandem solar cells. Our systems interconnect common cell formats.

At Module-TEC, we also have industrial systems for shingle interconnection. We develop and realize customer-specific shingle modules in string and matrix technology.

Intelligent encapsulation

We carry out intensive material tests and material combination developments for the encapsulation of solar cell strings. Our industrial laminator enables the production of PV modules in glass-glass and glass-foil technology. We develop and realize lightweight modules and master the 3D lamination of curved glass.

Unique simulation, analysis and characterization

For the development and evaluation of PV modules, we make use of the unique characterization and material analysis capabilities of Fraunhofer ISE. Both the analysis of joints in connection technology and the characterization of module materials are among our core competencies.