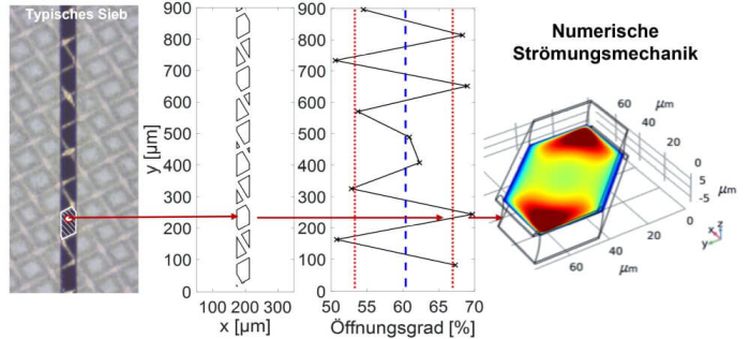

In addition to numerous 2D and 3D simulations of various printing processes, optical quality control methods are also being developed in the "Digitalization and Simulation of Printing Processes" work area. The methods are used by our research team in the context of digitization, with a particular focus on their application in the metallization of solar cells. These approaches aim to increase the efficiency and precision of metallization processes and thus contribute to the overall improvement of solar cell technology. By integrating advanced digital tools and optical control techniques, optimal process control is realized, which enables a deep insight into process parameter interactions. In combination with artificial intelligence, different processes can thus be better understood and optimized. With the help of inline quality control and 3D simulations, semantic data is generated which enables A.I. models to learn the relationships between input parameters and print results. As part of various projects, digital twins are being developed that enable real-time monitoring and precise control of various metallization processes. In the context of the metallization of solar cells, this offers the possibility of detecting and rectifying defects more quickly, resulting in fewer rejects and improved metallization quality.