Inkjet is a digital printing technique that enables the contactless and extremely precise application of various fluids (inks) as droplets. Fraunhofer ISE has many years of experience in the development of inkjet printing processes in which nano-scale metal particles, perovskites, waxy electroplating and etching barriers (including UV-curing ones) and dopants are printed with maximum resource efficiency and precision. For adequate wetting of inks on substrates, Fraunhofer ISE offers the complete portfolio for the characterization of media with regard to viscosity and surface tension. By using inkjet printers in glove boxes, the wetting environment can be adapted. Fraunhofer ISE also offers pre-processes for the activation of surfaces, for example using plasma.

Inkjet

Our Infrastructure and Services for Inkjet:

- Various setups (including glove boxes) with different print heads for the development of inkjet printing processes (semi-industrial systems, laboratory systems)

- Process integration of inkjet printing processes into the core applications of Fraunhofer ISE (such as silicon-based solar cells)

- Development of components for the conditioning of substrates

- Rheological tests on inks in inkjet-relevant frequency ranges (1 kHz)

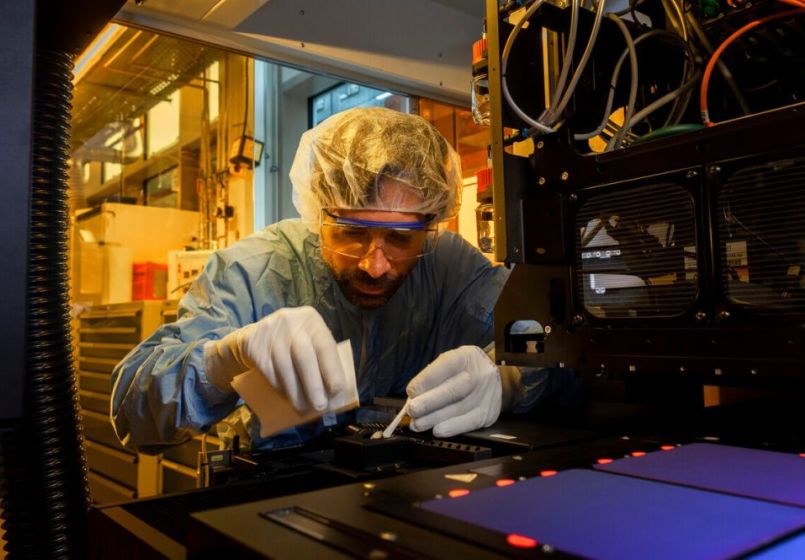

Solar cell printing with inkjet systems at Fraunhofer ISE. Four industrial solar cells are processed in one process in order to increase throughput.

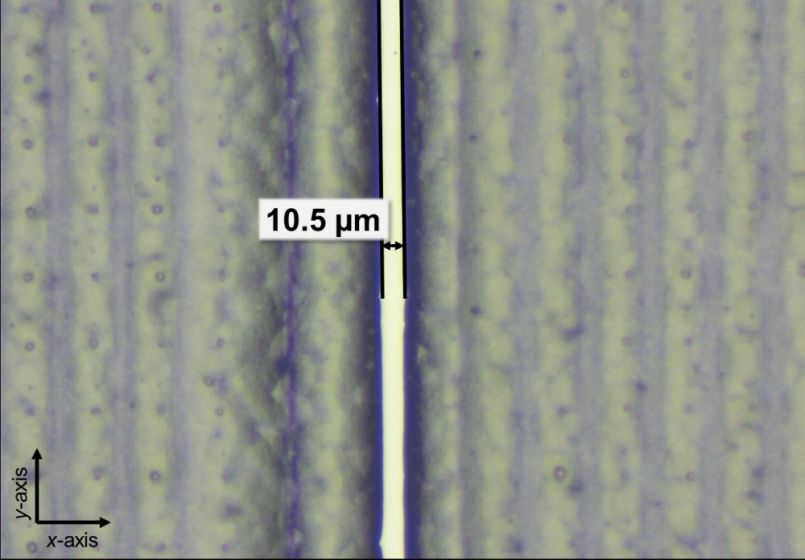

Top view of an inkjet-printed electroplating barrier (mask) with an opening structure width of 10.5 µm using Mask&Plate technology. In addition to the electroplating barrier application, the inkjet-printed structures can also be used as an etching barrier.

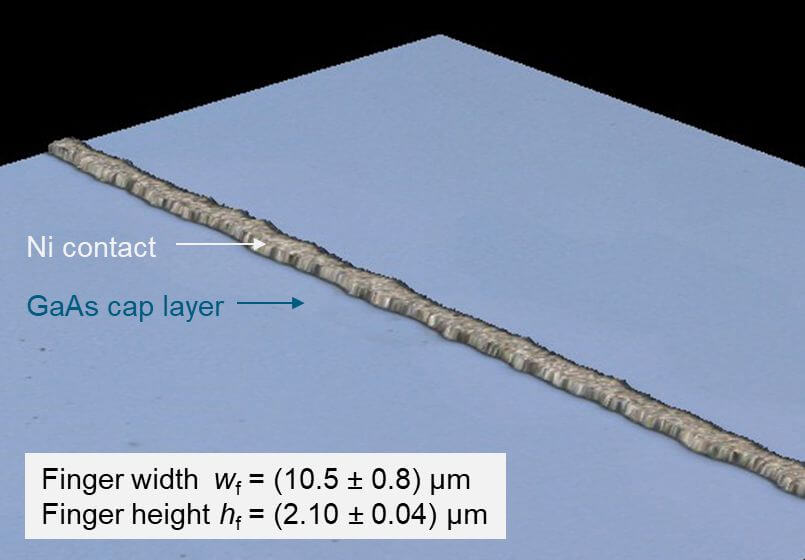

Plated electrode defined with inkjet using Mask&Plate technology for contacting high-efficiency solar cells (here: III-V solar cells).