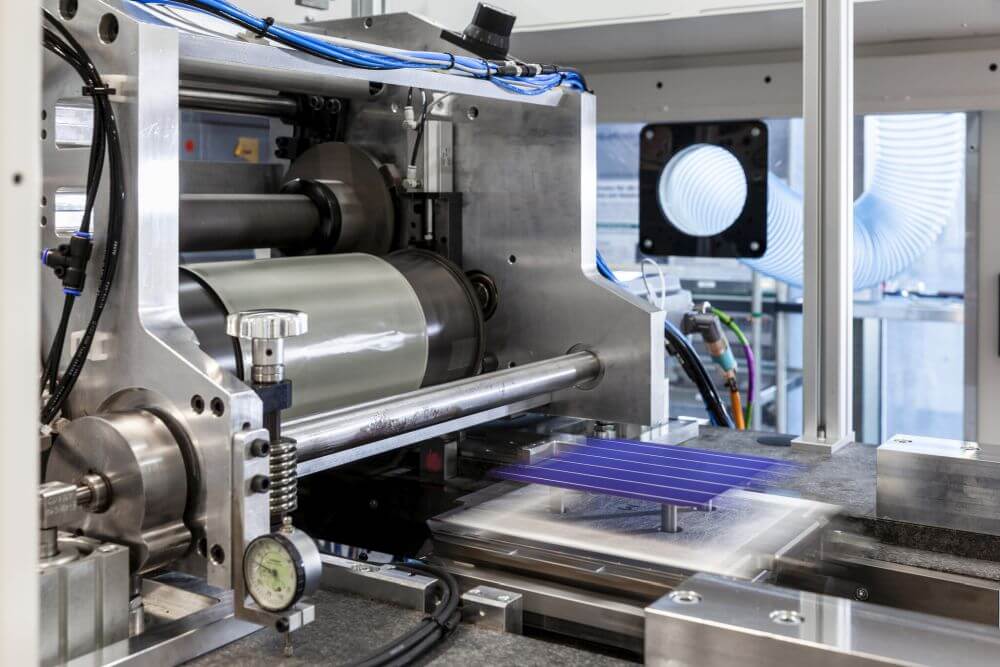

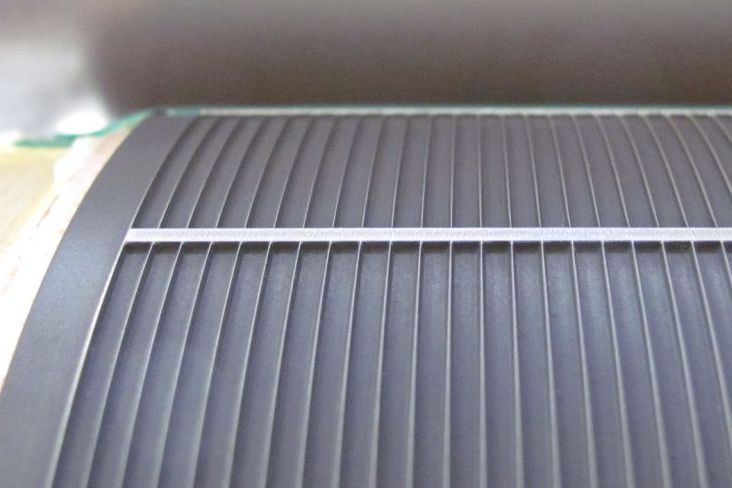

Rotary printing processes such as flexographic printing, rotary screen printing and gravure printing have been used in a wide range of industrial applications in the graphic and technical sectors for decades. Rotary printing processes are unique in terms of speed, precision and flexibility. Normally, web-shaped substrates are printed using rotary printing processes. However, printing on non-flexible substrates such as silicon solar cells, printed circuit boards, electronic components or chip cards is much more demanding. Coating such substrates at high printing speeds requires a high-precision transport system and precise alignment of the rotary printing units.

Such a technology was developed at Fraunhofer ISE in collaboration with project partners for the metallization of silicon solar cells and other functional applications. The use of rotary printing processes combines the high-precision transfer of extremely fine structures with a high throughput and thus a substantial increase in productivity. Beyond the metallization of silicon solar cells, this technology also offers great potential for a wide range of applications in the field of functional and technical printing.