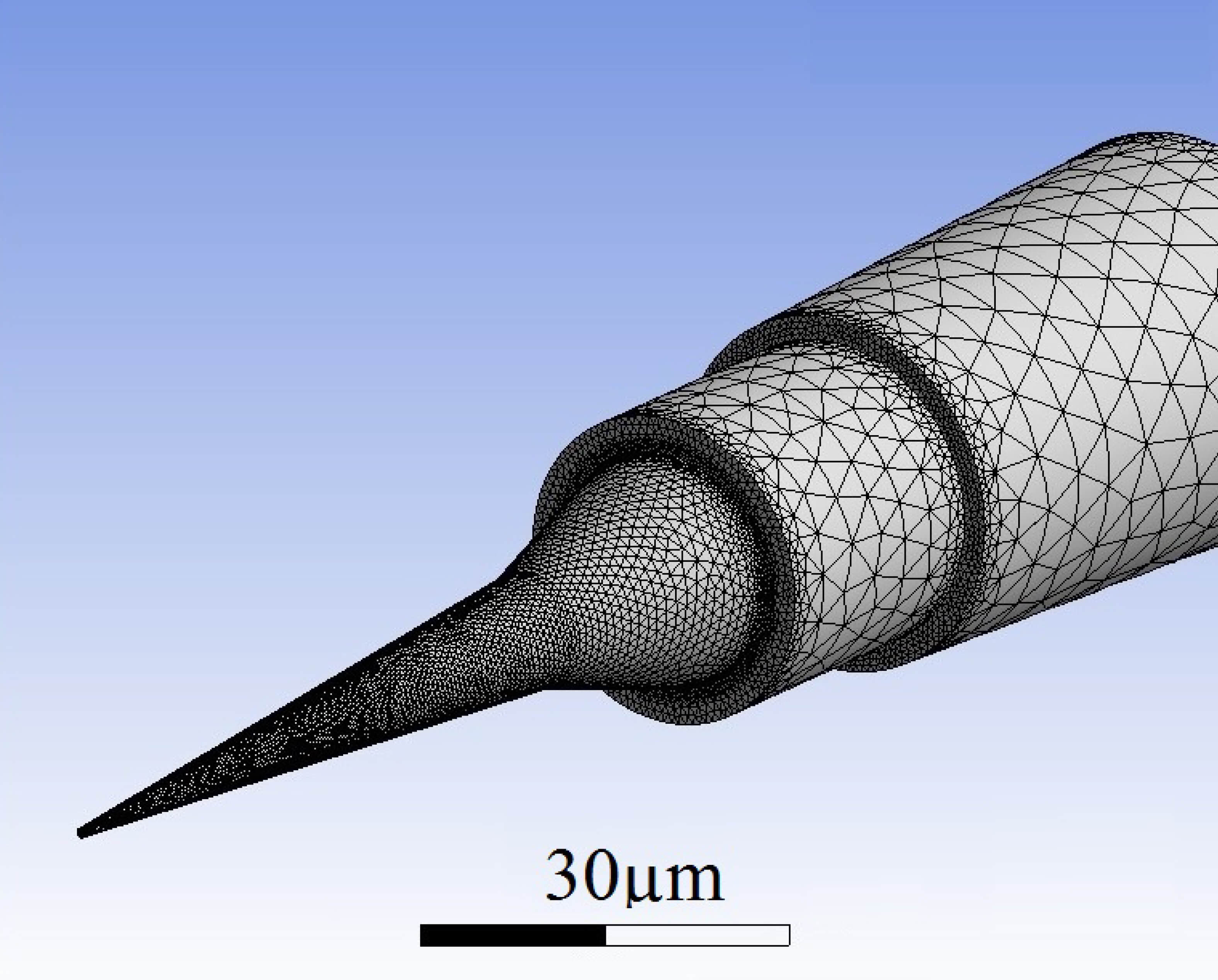

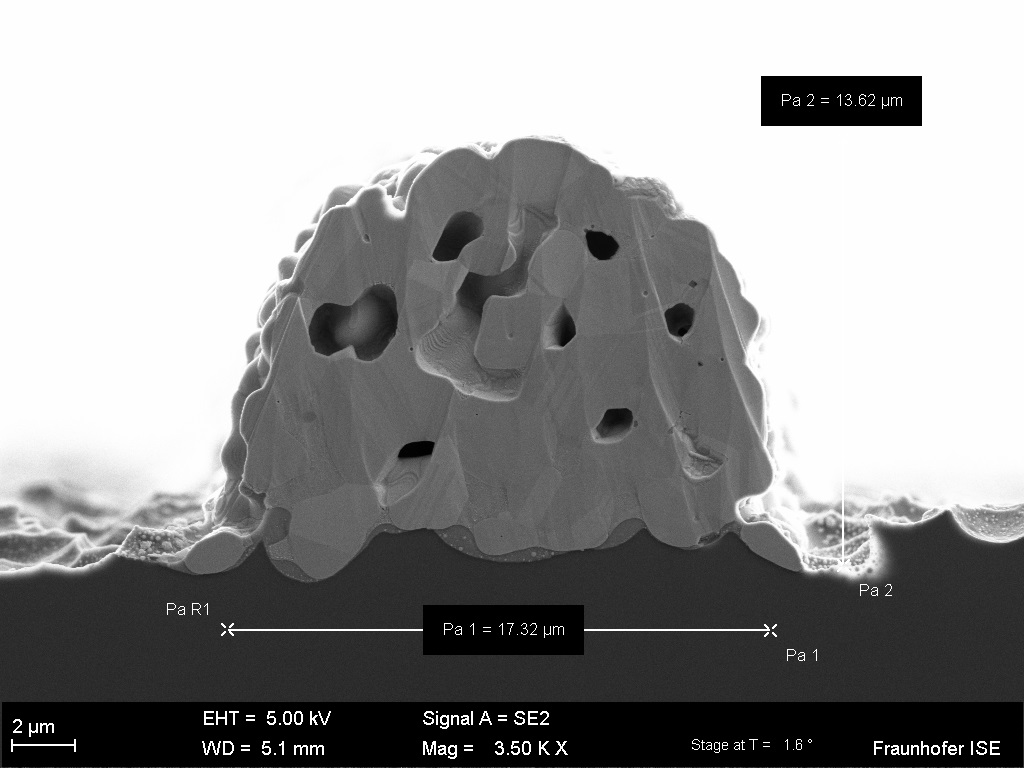

Dispensing is used in many areas of industrial production as a process for precise dosing and accurate positioning of fluids (silicon PV, thin film, etc.). Dispensing requires high-precision manufacturing of the nozzles, fast and micrometer-precise control of the dispensing head via the substrate and intensive rheological optimization of the fluids used. Dispensing can be used to produce very homogeneous structures with almost perfect shape and uniformity, for example ideal conductor structures with the finest line width and minimal deviations. A special feature is multi-nozzle dispensing, which combines the advantages of precision with high throughput. With multi-nozzle dispensing, the finest contact fingers, e.g. for the front side metallization of silicon solar cells, can be transferred in a highly parallel manner with perfect geometry and high throughput. However, the process also offers great potential for other applications. Multi-nozzle dispensing was developed at Fraunhofer ISE with the help of CFD simulations and has been commercialized by Highline Technology - a Fraunhofer ISE spin-off - since 2020.

Our infrastructure and services for dispensing:

- Industrial platform with high-precision 3-axis positioning system and multi-nozzle dispensing print head

- Laboratory equipment for single and multi-nozzle dispensing

- Development of specific print media with filament stretch effect to achieve the smallest structure sizes