| Duration: | 09/2020 - 05/2024 |

| Contracting Authority/ Sponsors: | Bundesministerium für Wirtschaft und Energie (BMWi) |

| Project Partners: | teamtechnik Maschinen und Anlagen GmbH |

| Project Focus: |

ElVis – Electric Battery Interconnection: Innovative, Flexible, Fast and Cost-Effective

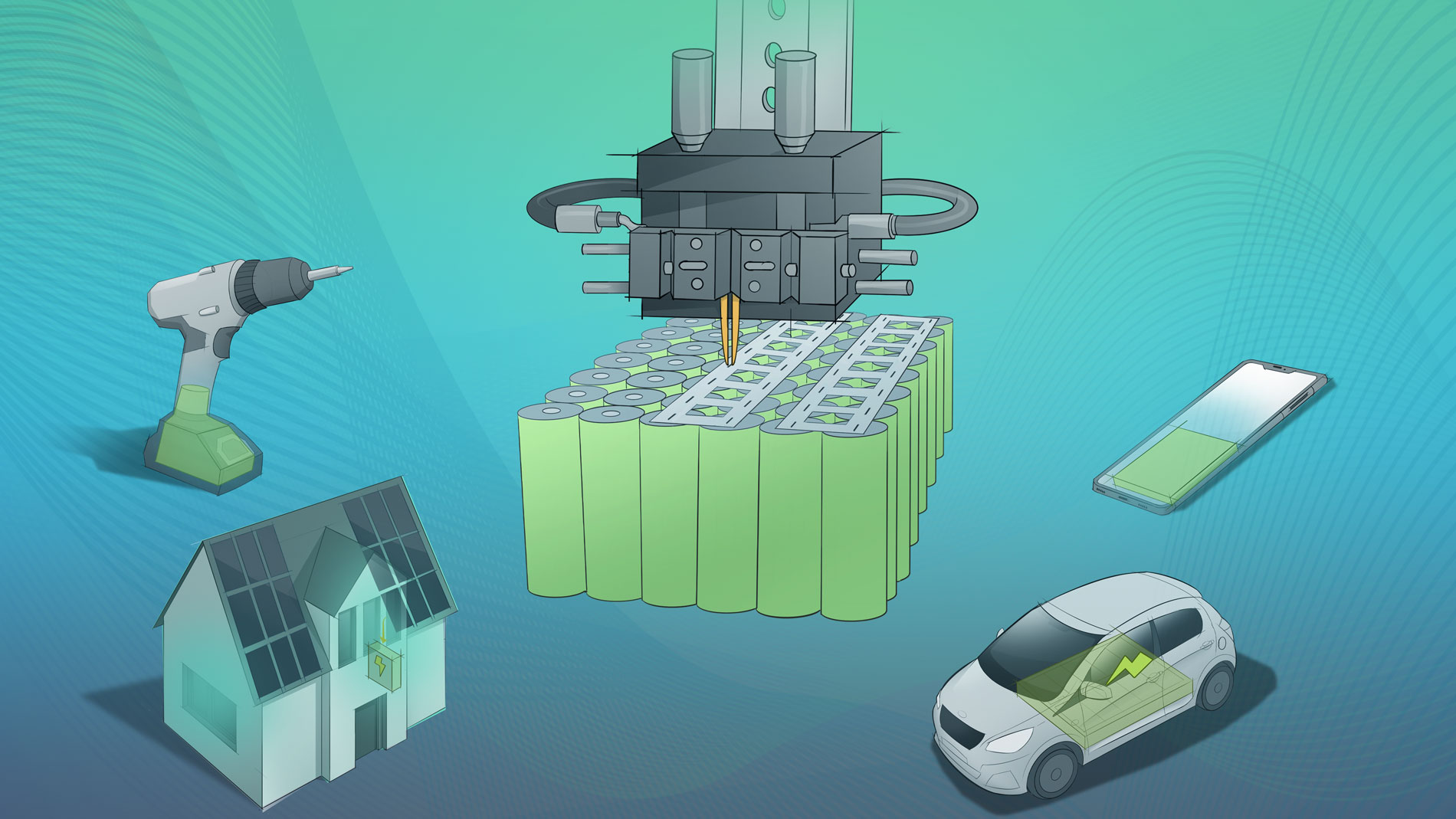

The use of electricity from renewable sources requires suitable storage systems for the constant supply of electricity from wind and solar energy. To achieve the necessary current and voltage characteristics of battery-powered devices, individual battery cells are assembled into battery modules or battery packs and electrically connected in series or parallel. The aim of the »ElVis« project is to develop a flexible interconnection system for battery cells. The interconnection technology of resistance welding of round battery cells is to be further developed and optimized.

An innovative modular principle is being designed for variable battery pack sizes and resistance welding variants and implemented by setting up a demonstrator system.

The modular principle will enable different battery module sizes to be interconnected cost-effectively with one system in the future. The development of connector dimensioning models will support time-efficient, material-saving and reliable interconnection.

Design interconnection system and build demonstrator system

The aim is to design and build an interconnection system for battery packs with a flexible interchangeable design for different battery pack sizes and interconnection technologies. The system is intended to interconnect round-cell battery packs quickly and cost-effectively for a wide range of applications from electromobility to the consumer sector. The technological focus is on the design of an intelligent modular principle and the development of transfer and handling systems through the use of linear drives and lightweight robots as well as human-machine interactions.

Investigate and optimize interconnection processes

With the optimization of the interconnection of battery cells, the project aims at the central manufacturing step in the production of battery modules. In order to precisely understand the welding processes at the interconnection points, the resulting joints are examined in detail electrically and mechanically. Our characterization methods from the field of solar cell interconnection are used here. The critical process parameters can be derived from the analysis results. In addition, the integrated sensor technology in the welding heads will allow conclusions to be drawn about the process control. With the knowledge gained, a detailed and targeted process development for resistance welding of battery cells can be carried out. The aim is to establish a favorable process for interconnecting high-current-capable connectors. The welding of cell connectors made of copper and aluminum is being investigated.

Ensuring quality with foresight

Flexible production through automatic evaluation of the welding parameters and the weld seam quality (keyword: predictive process maintenance) is in the foreground. This enables conclusions to be drawn about the electrode condition of the joining head in operation and thus precise planning of change, cleaning or calibration intervals, and production scrap is reduced. Furthermore, the required precision of the system for depositing, holding down and contact pressure of the connectors in the process is an important parameter that influences both the throughput and the quality of the resulting joint and for this reason should be considered in detail.

Develop models for optimal connector sizing

On the basis of the experimentally obtained findings and the electrical and mechanical parameters of the materials used and the production-related boundary conditions, models are to be developed that enable the calculation of the optimum connector dimensions for various applications. This will enable a producer of battery packs to easily and quickly calculate an interconnection for a desired battery pack. For the development, FEM simulations on the electrical and mechanical properties of the cell connectors and the interconnection will be carried out in the project.

Evaluate plant and process development techno-economically

The techno-economic evaluation of the equipment and process development in the project realizes the elaboration of the technical and economic benefits of the developed equipment and process technology for the customer in comparison with the available equipment stock. In addition, it evaluates how well the developed technologies fit into the requirements of a variable market, with constant change and new technology trends.